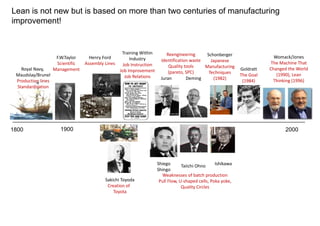

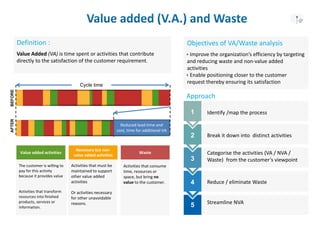

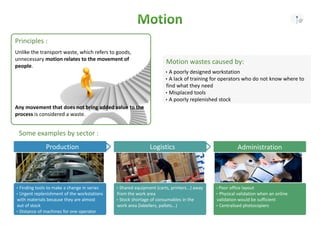

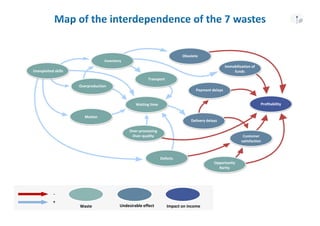

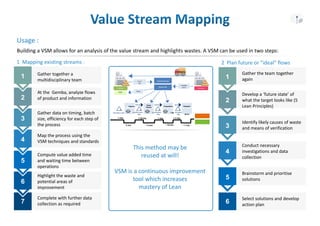

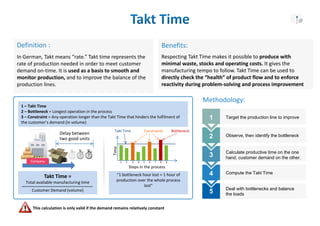

Lean thinking is based on over two centuries of manufacturing improvement. It aims to improve efficiency by targeting and reducing waste and non-value added activities through identifying value-adding activities from the customer's perspective, categorizing all activities, breaking processes down, and streamlining non-value added activities. The main types of waste are overproduction, waiting time, transport, over-processing, inventory, motion, defects, and unused employee skills. Lean principles focus on specifying value, identifying all process steps, removing barriers to smooth and continuous flow, and continuously improving to achieve perfection.