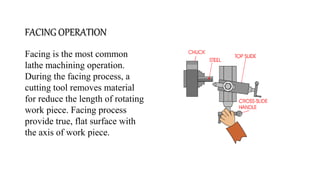

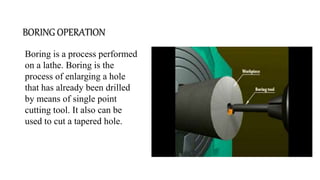

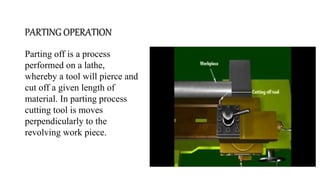

This document provides an overview of lathe machines. It begins with an introduction that defines a lathe as a machine tool used to remove metal to shape and size workpieces. It then covers the history of lathes, classifications of different lathe types, the main parts of a lathe, how lathes work, and common lathe operations such as turning, facing, drilling, boring, grooving and parting. The document concludes that lathes are heavy-duty tools widely used in engineering to cut, shape and drill metals, woods, plastics and other materials.