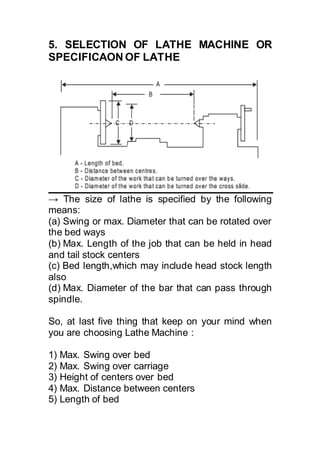

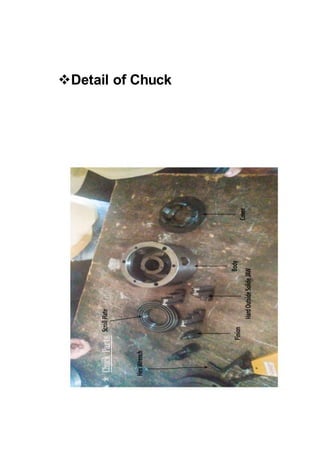

This report summarizes a lathe machine. It begins with an introduction on the history of lathes and the difference between manufacturing and production. It then discusses the construction details of various types of lathes. The report outlines the materials used for cutting tools and safe operation of lathes. Selection criteria for choosing a lathe machine is presented. Finally, dangers, safety practices, and maintenance of lathe machines are covered. Photos further illustrate the details of lathe machines.