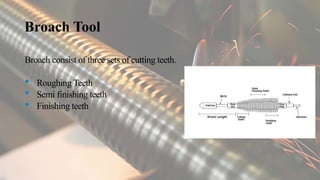

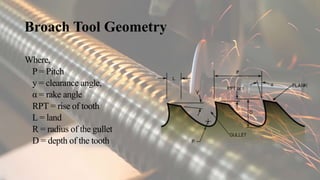

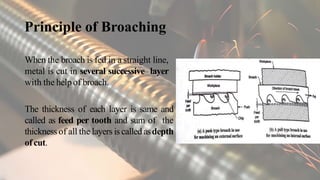

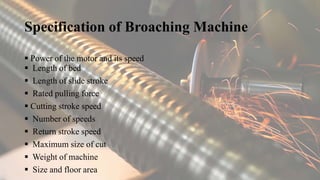

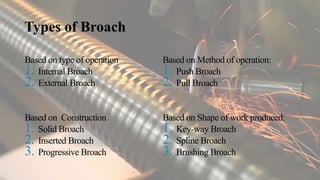

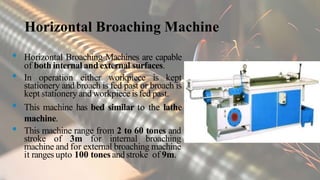

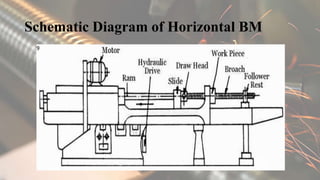

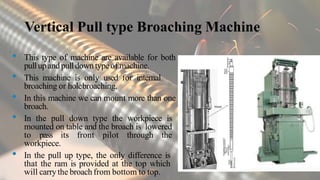

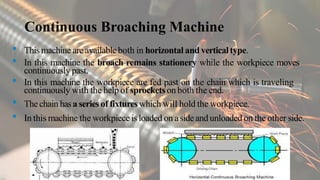

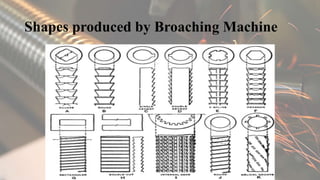

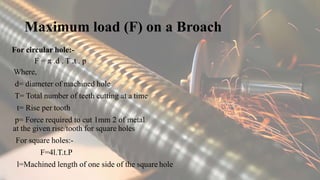

The document discusses broaching machines and the broaching process. Broaching involves using a broach tool with multiple cutting teeth to machine internal or external surfaces. Broaching machines include horizontal, vertical pull, continuous, and rotary table types. Broaching produces parts with good dimensional accuracy and surface finish. It is commonly used to cut keyways, splines, and other features on mechanical components.