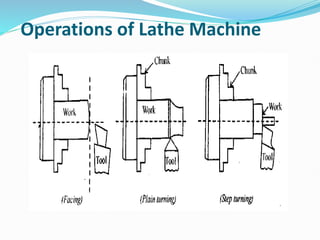

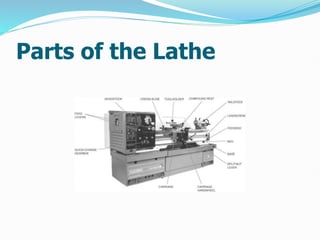

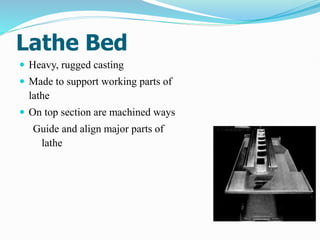

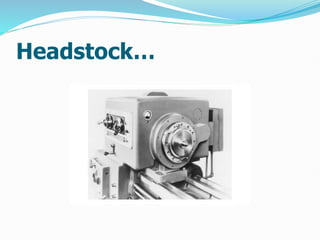

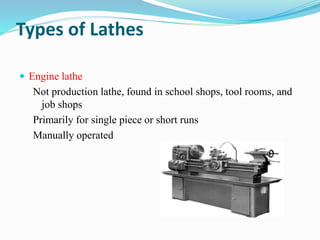

The document provides a comprehensive overview of lathe machines, detailing their history, operations, parts, advantages, and different types. It describes the lathe's functionality as crucial in metalworking and highlights its evolution from early wood lathes to modern CNC technology. The document emphasizes the machine's significance in producing precise components and its wide-ranging applications in various industries.