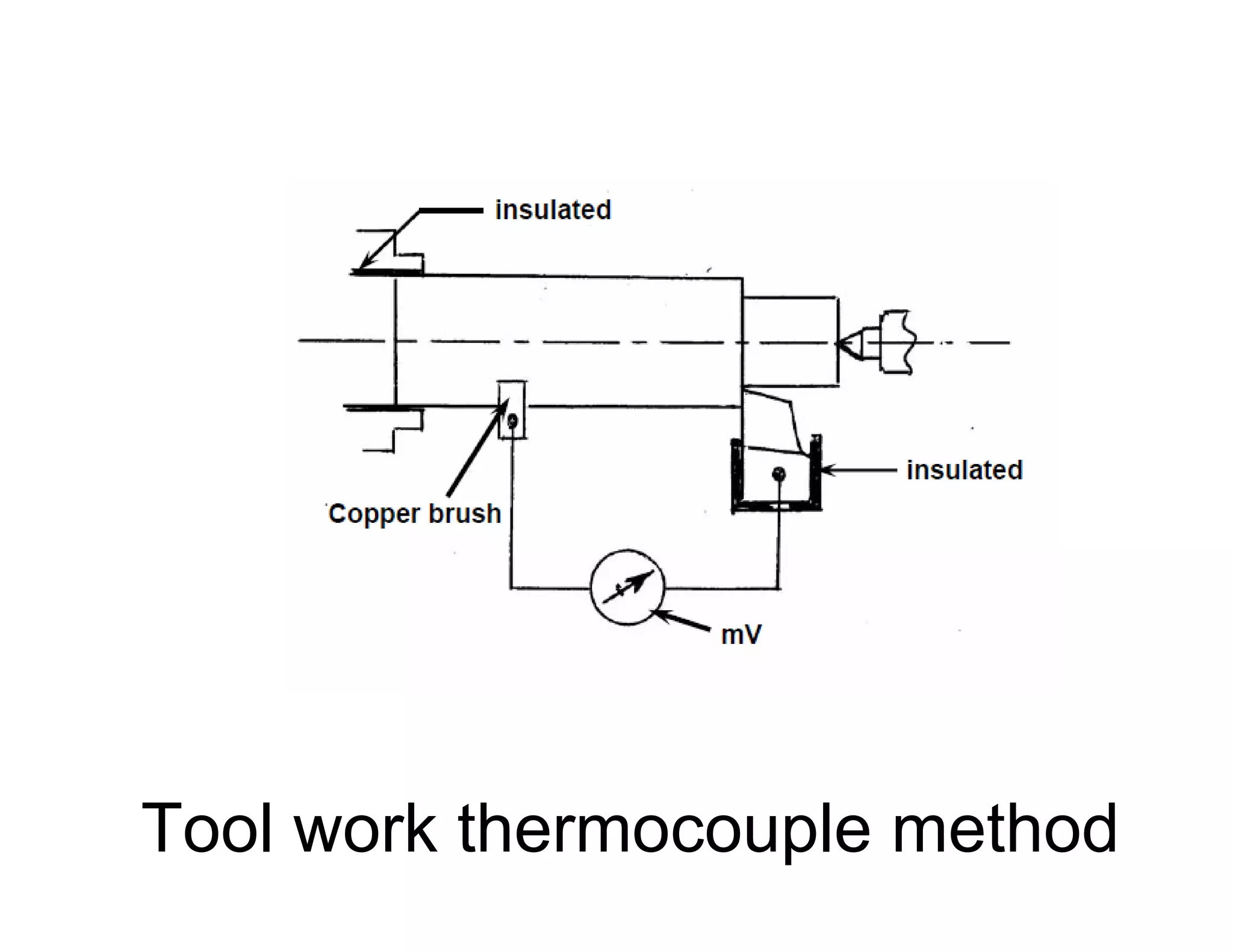

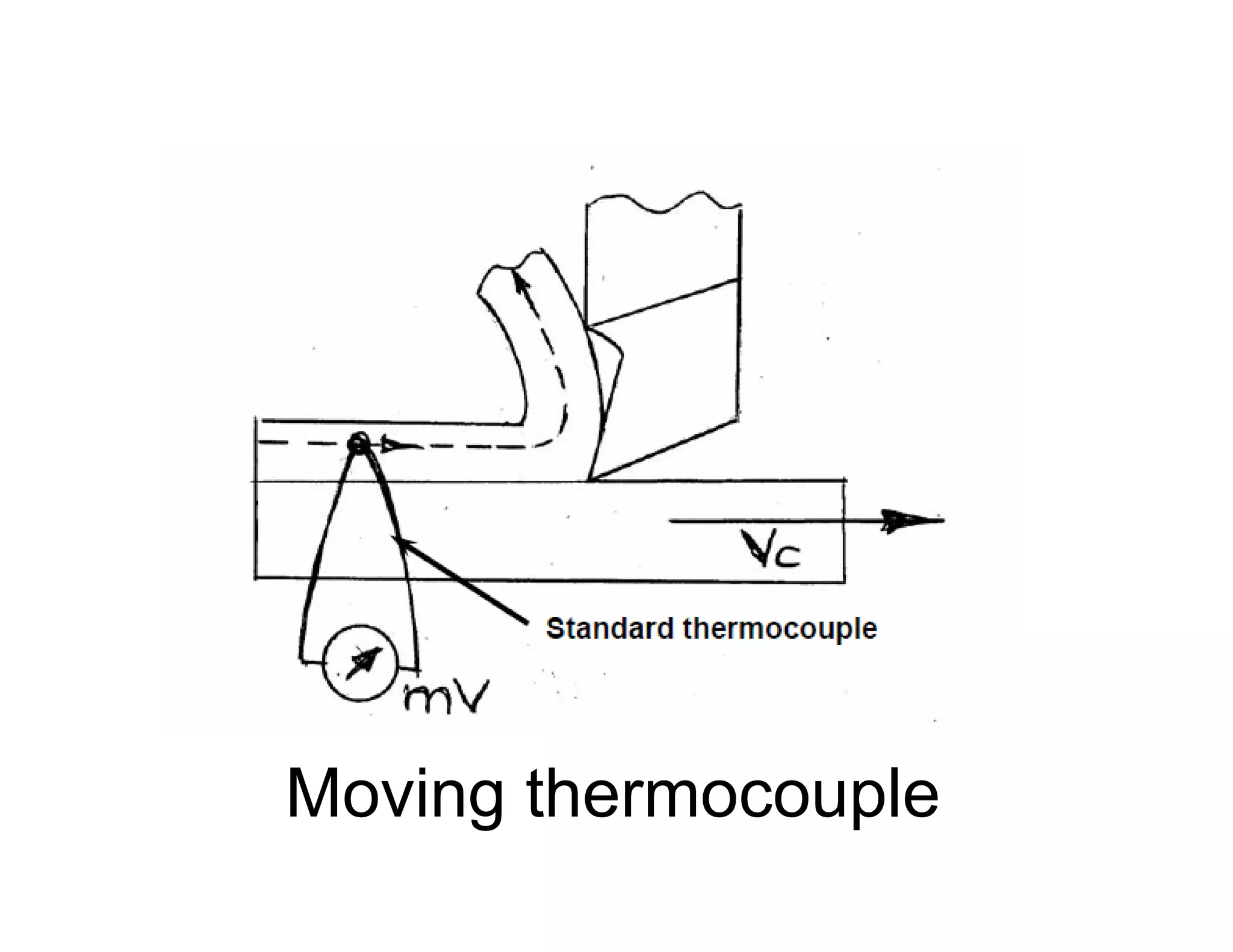

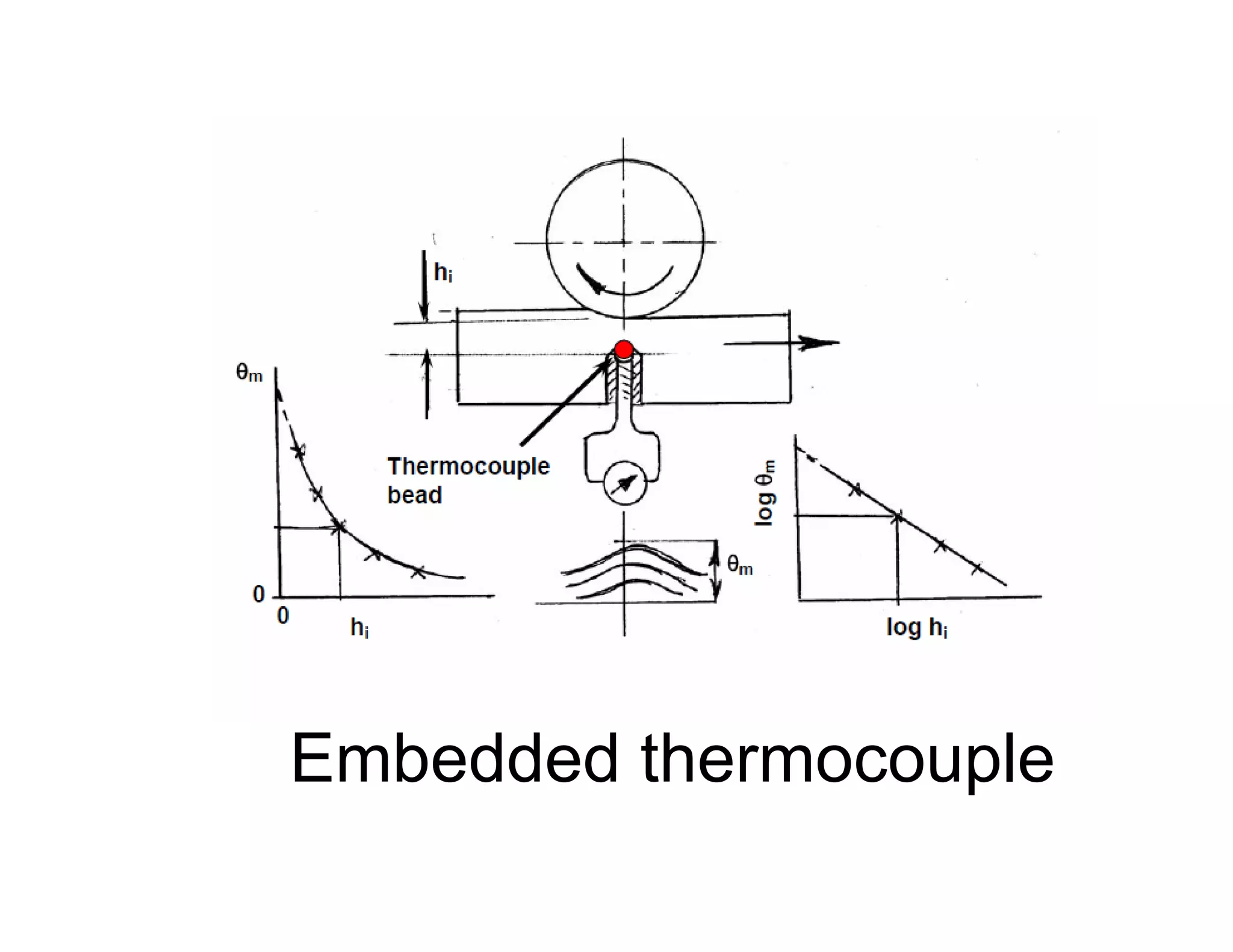

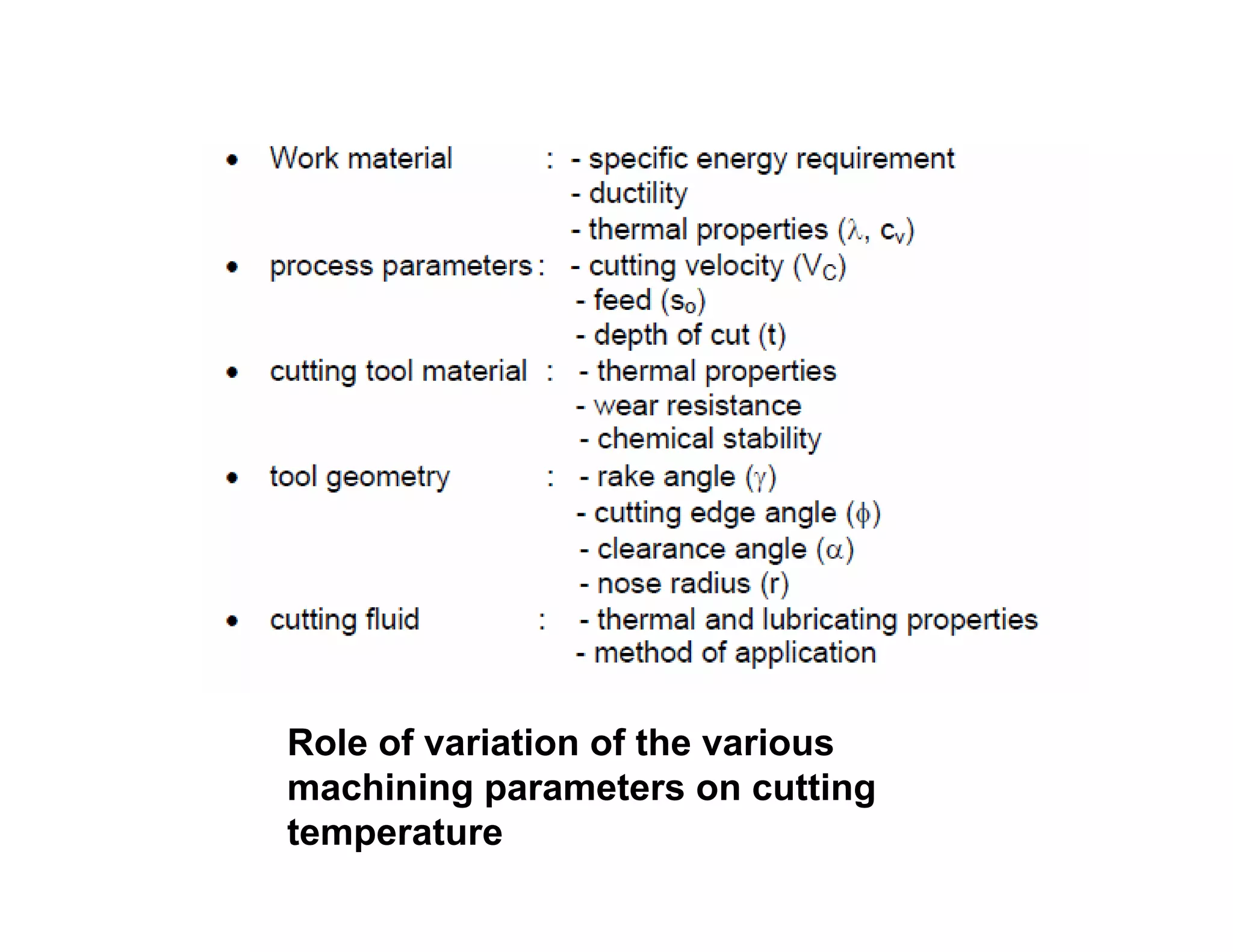

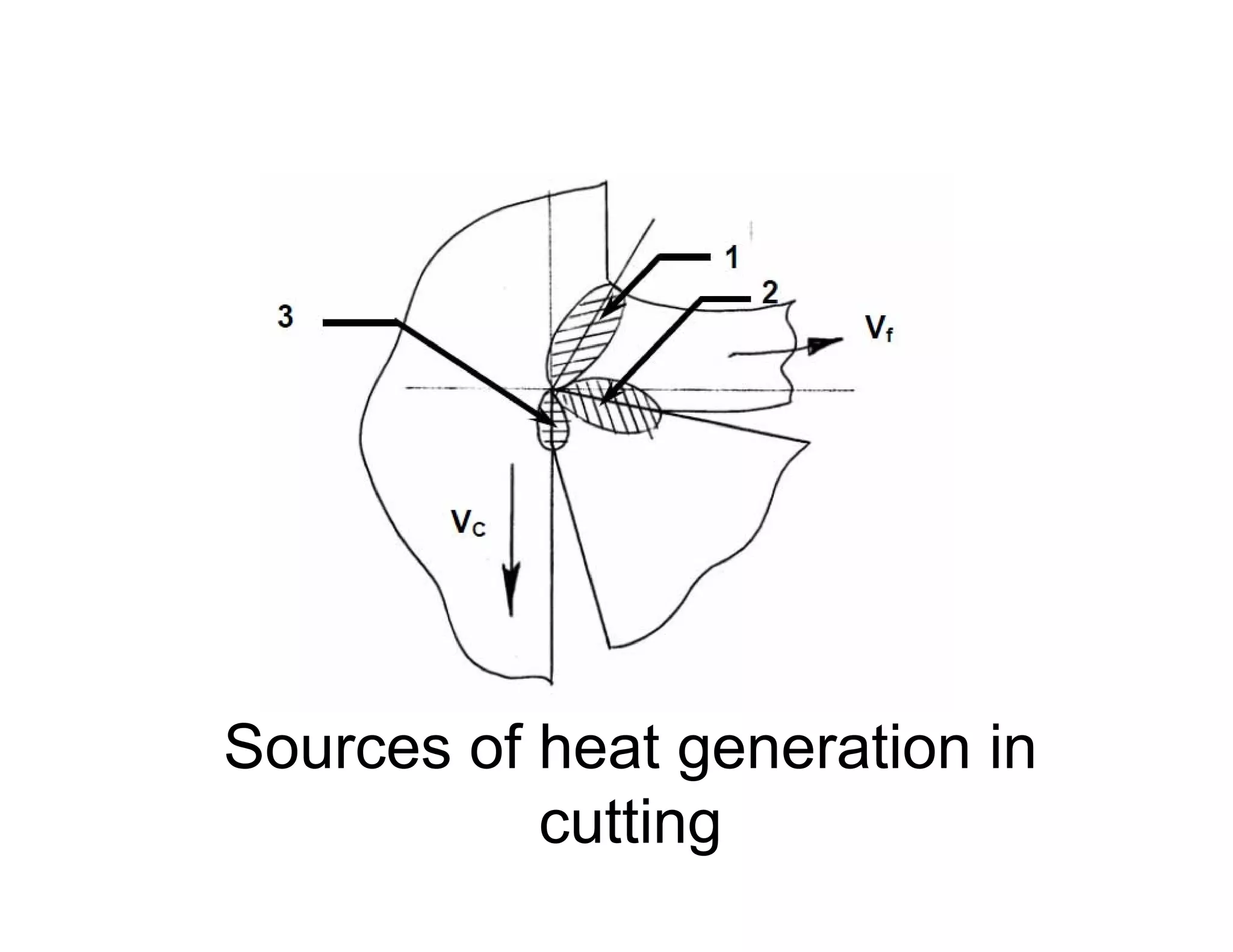

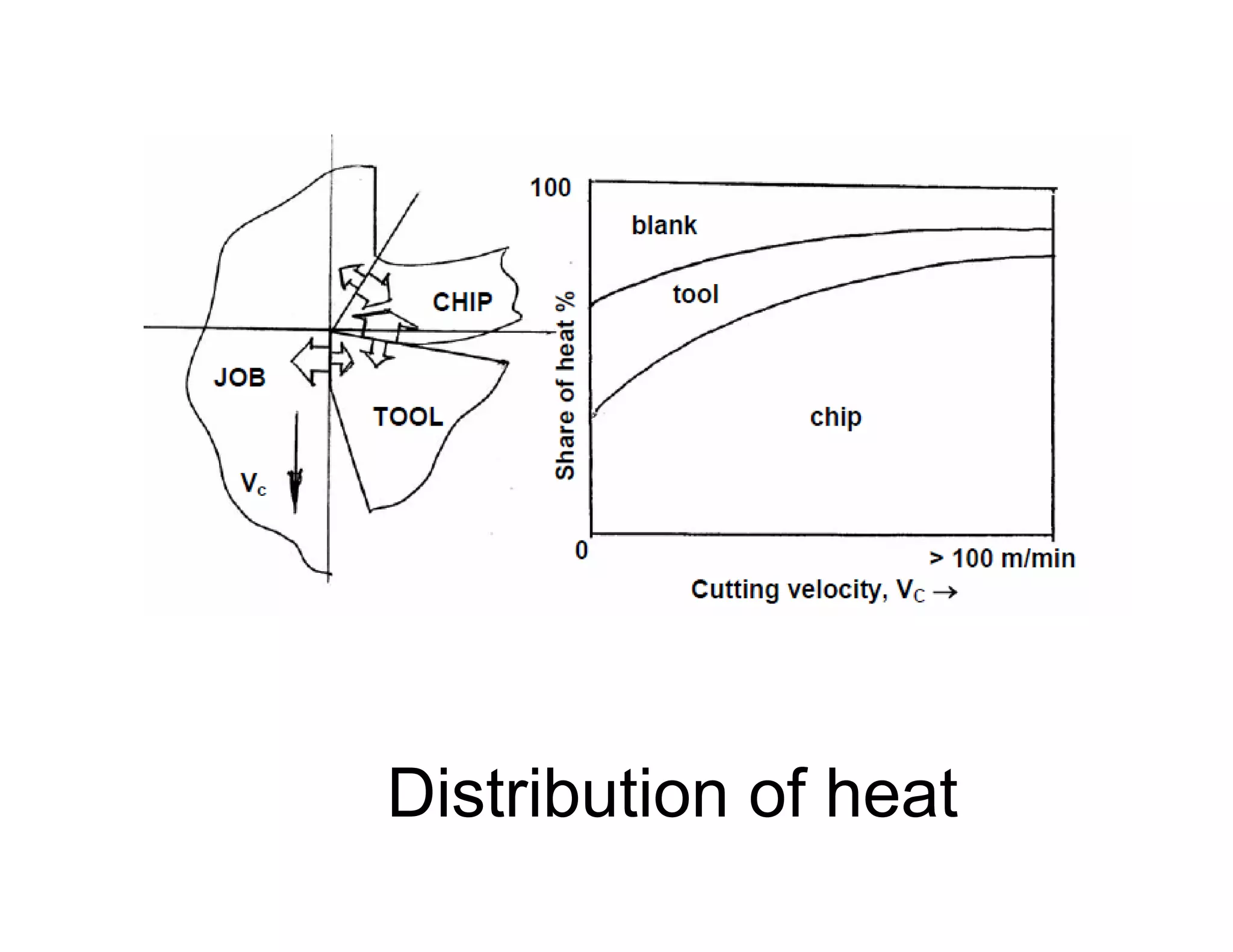

This document discusses cutting temperature in machining. It outlines sources of heat generation during cutting including plastic deformation and friction. High temperatures can cause rapid tool wear, thermal damage to the workpiece, and residual stresses. Measuring temperature helps assess machinability, select cutting tools and fluids, and analyze temperature distribution. Important parameters include shear zone temperature, chip-tool interface temperature, and work-tool interface temperature. Both analytical and experimental methods are used to measure temperature, such as tool work thermocouples, moving thermocouples, and infrared techniques. Varying machining parameters impacts cutting temperature.

![is a function of shear angle Φ

and non dimesional quantity Ə

Ə= ƿcVt1/k

k-thermal conductivity of the material

ß =0.15 ln (27.5/ Ə tan Φ)

√

ƟS + 1.13 [ (Ət2/l)(Ws/ƿcvwt1)]

l - length of contact bet.tool and chip](https://image.slidesharecdn.com/cuttingtemperature-120104221648-phpapp02/75/Cutting-temperature-9-2048.jpg)

![Ɵs av = Ws/ƿcvwt1

l/t2 = [1+tan (Φ -α )]

Ɵs=1.13 √(1/ƿcvt1k[1+tan (Φ -α )] (Ws/w)

Ɵ= Ɵ0+ Ɵp +ƟS](https://image.slidesharecdn.com/cuttingtemperature-120104221648-phpapp02/75/Cutting-temperature-10-2048.jpg)