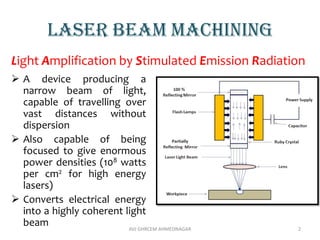

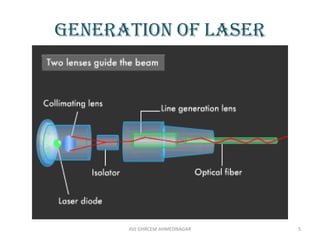

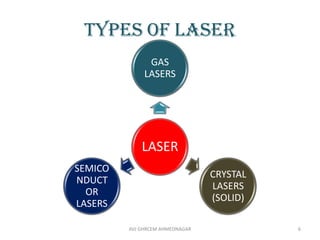

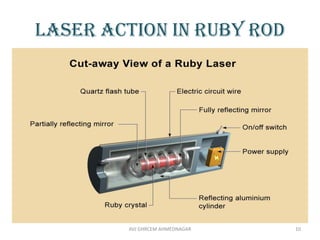

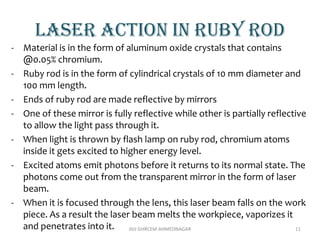

The document provides an overview of the laser beam machining (LBM) process, including its principles, types of lasers, setup, advantages, disadvantages, and applications. It highlights different laser types such as gas, solid, and semiconductor, and explains the operational setup involving a ruby rod, flash lamp, cooling system, and lens arrangement. LBM is noted for precision machining capabilities, although it comes with high costs and requires skilled operation.