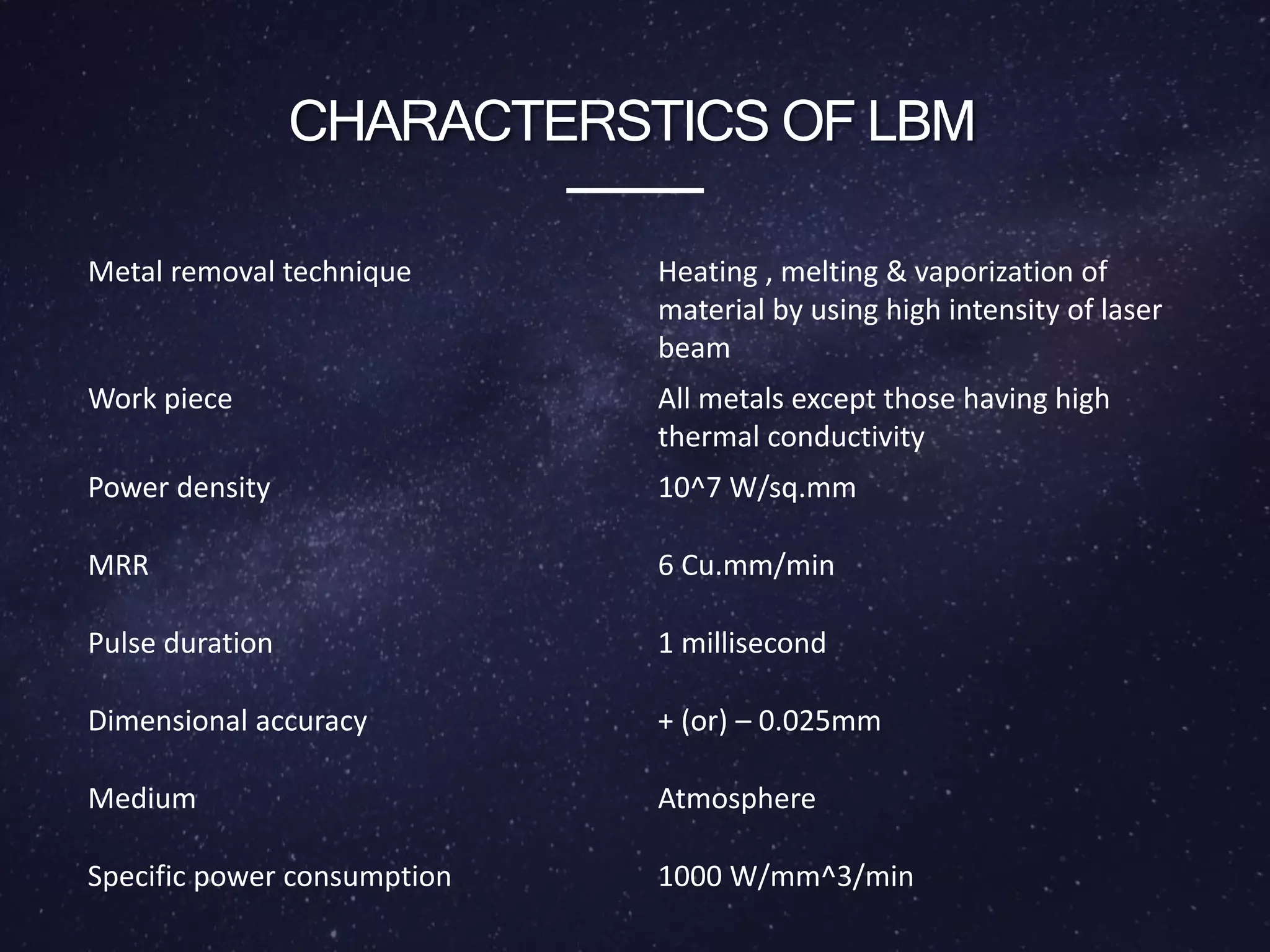

Laser Beam Machining (LBM) is a nonconventional process that uses high-energy laser beams to heat, melt, and vaporize workpiece materials. While LBM offers advantages like low tool wear and the ability to machine various materials, it has disadvantages such as low energy efficiency and challenges in producing deep or blind holes. Applications include macro machining, surgery, and micro-drilling, making LBM a versatile method for complex machining tasks.