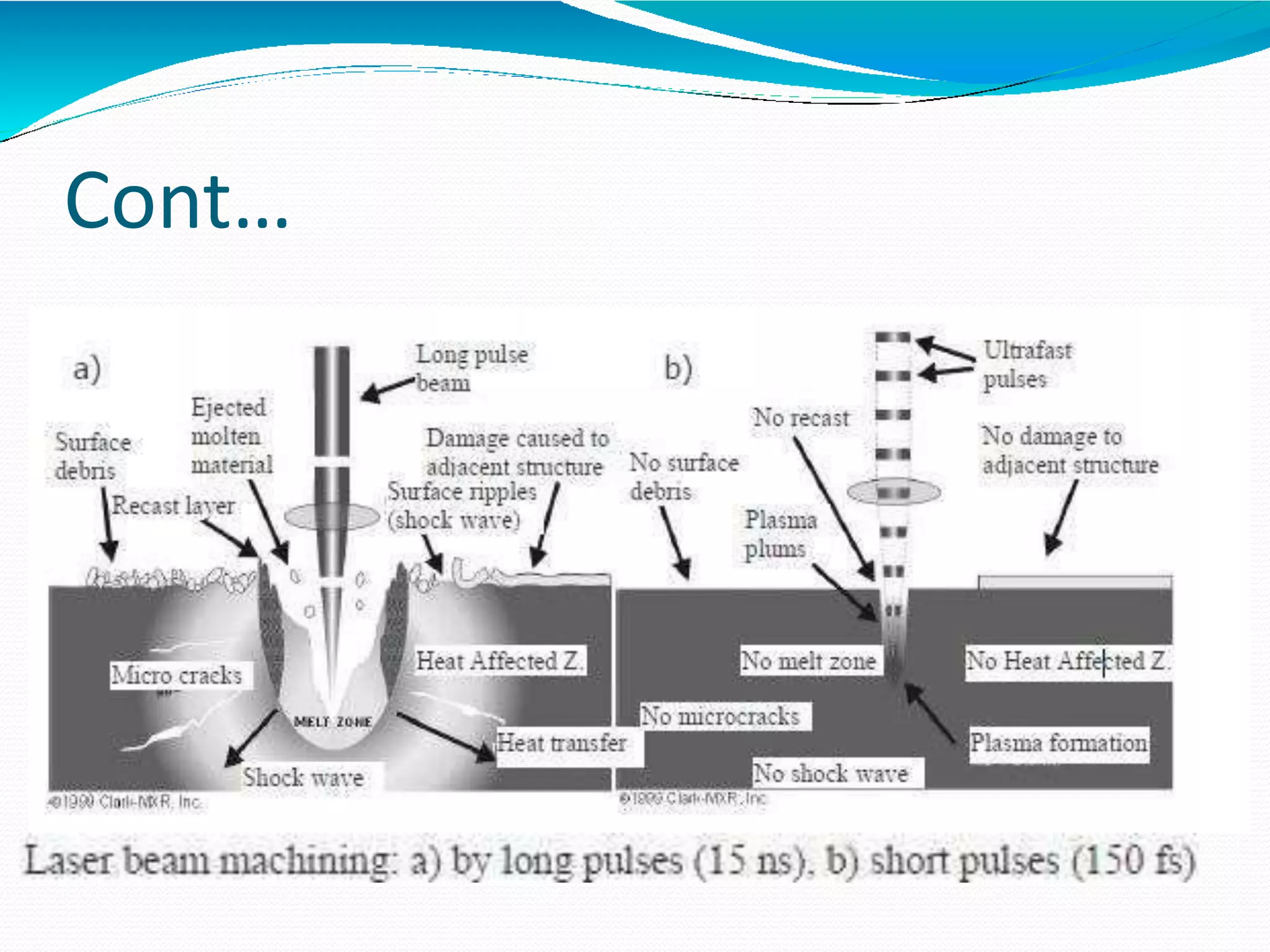

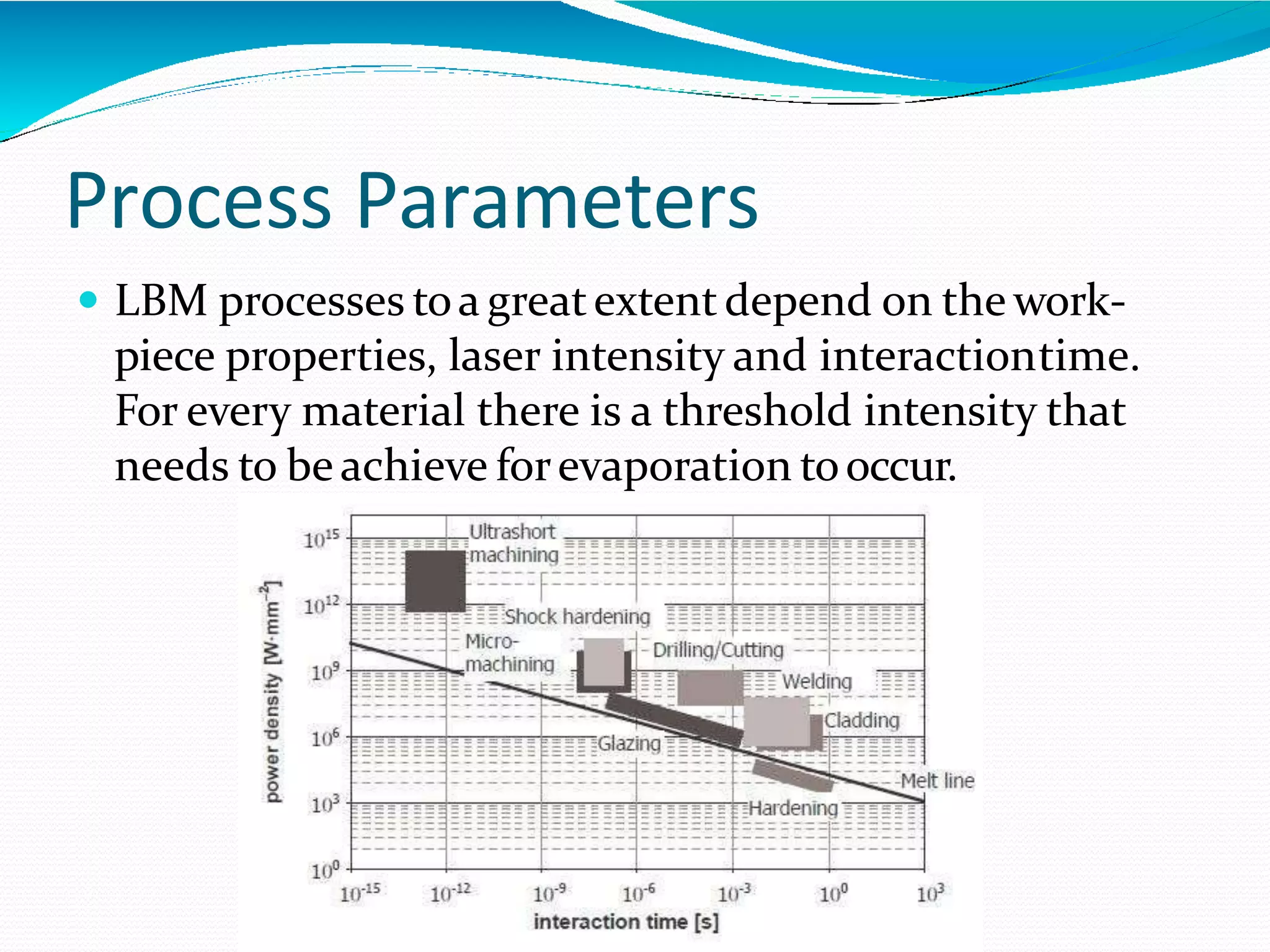

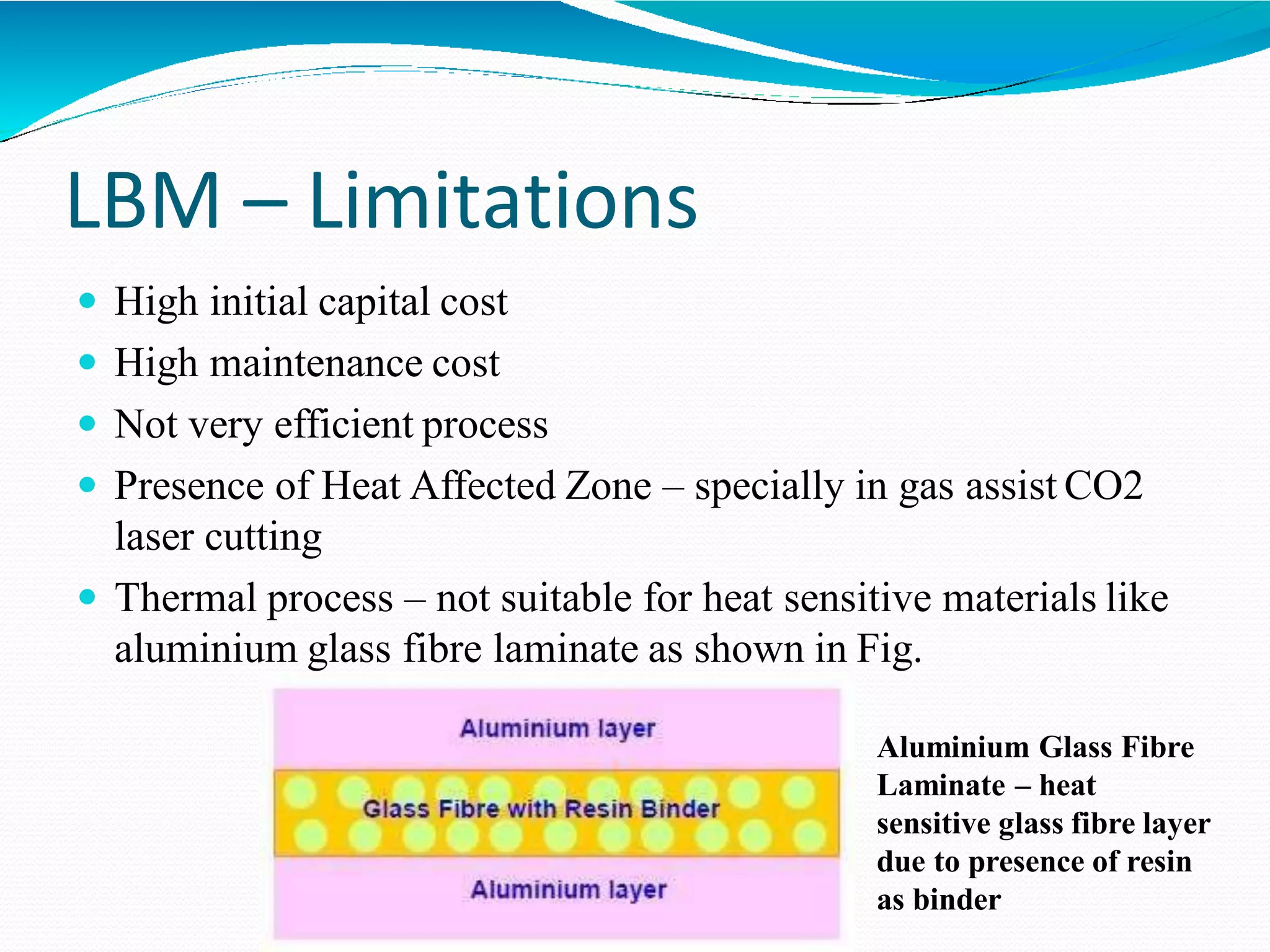

The document discusses laser beam machining (LBM), noting that laser light can break chemical bonds due to its amplified, monochromatic, polarized, and coherent properties. LBM uses laser energy to carry out processes like machining, heat treatment, and rapid prototyping. During LBM, laser energy is absorbed by the work material, causing rapid heating, melting, vaporization, and removal of material. The removal rate depends on factors like laser intensity, exposure time, and material properties. Key applications of LBM include drilling, cutting, welding, and cladding. Advantages are high precision and no physical tool wear, while limitations include high costs and thermal effects.