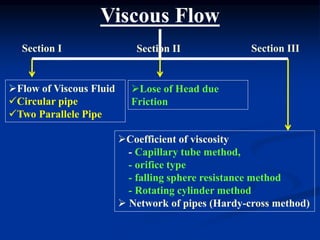

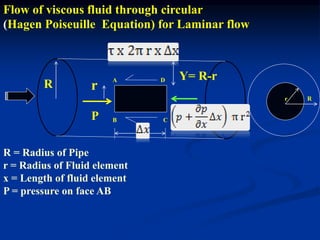

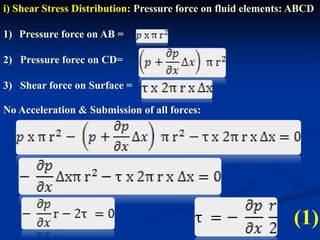

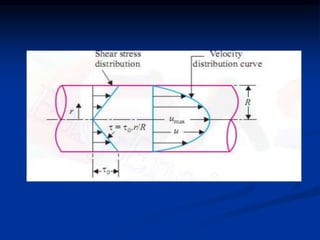

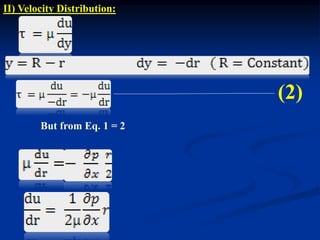

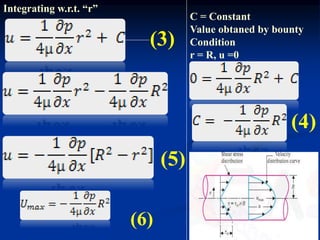

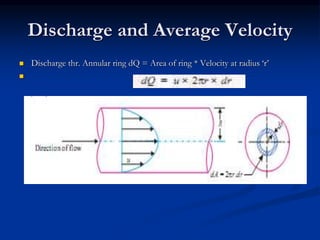

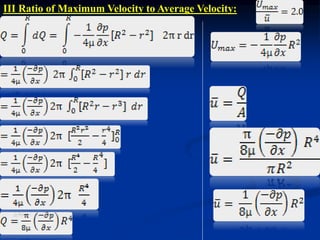

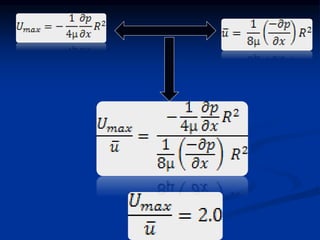

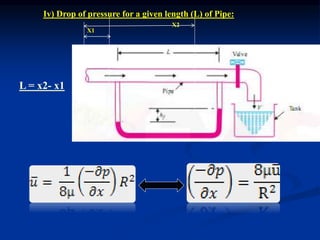

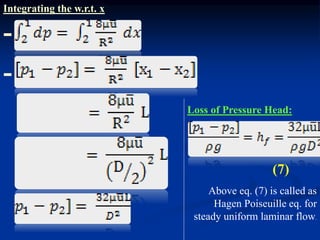

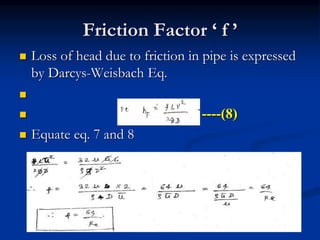

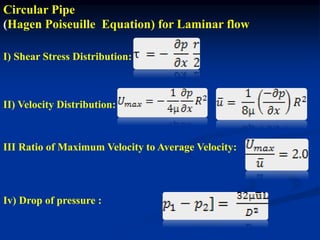

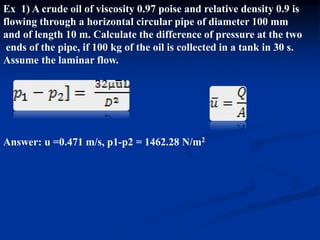

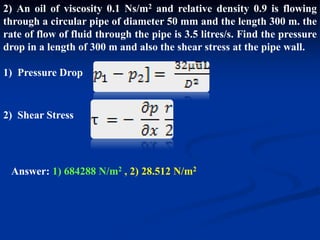

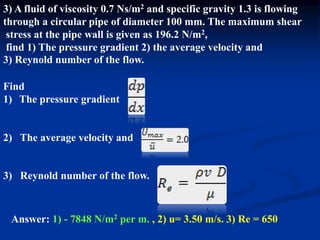

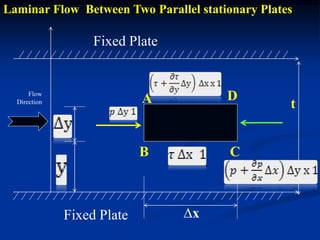

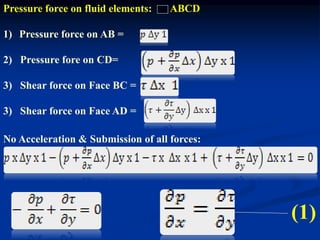

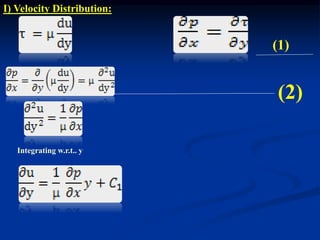

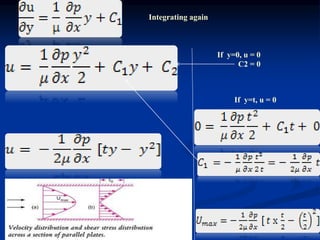

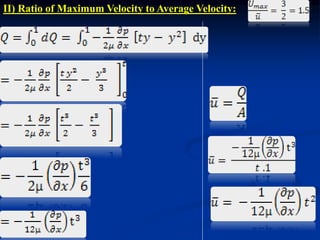

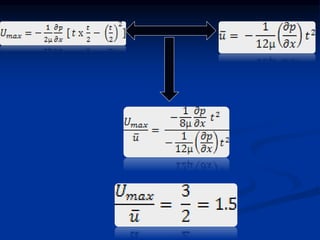

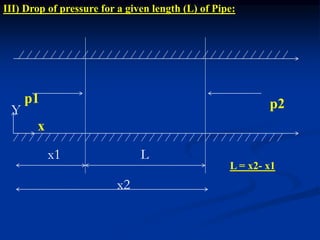

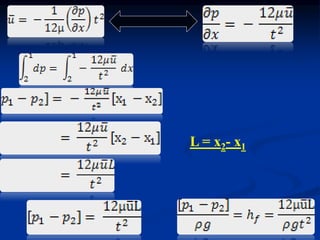

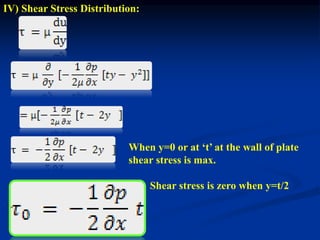

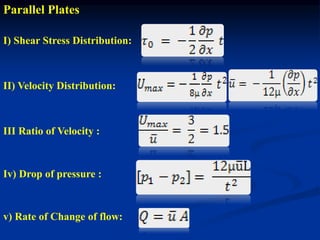

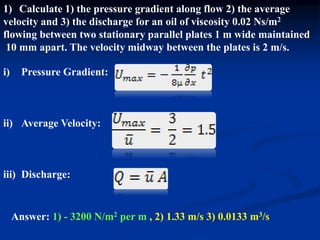

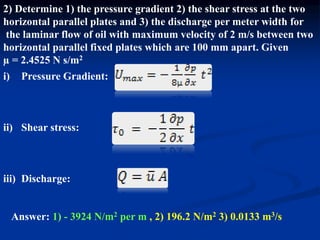

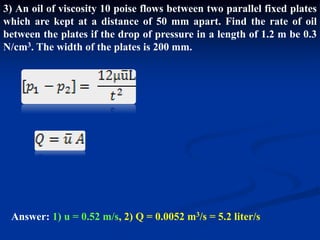

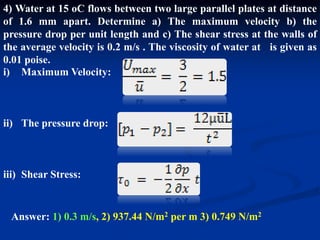

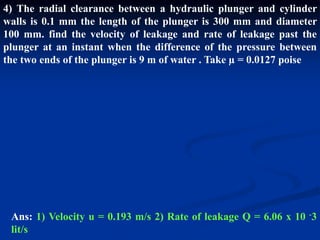

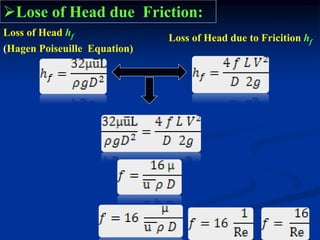

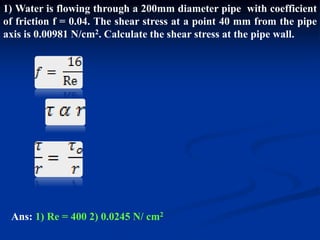

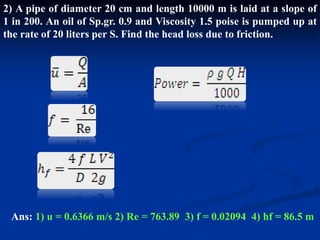

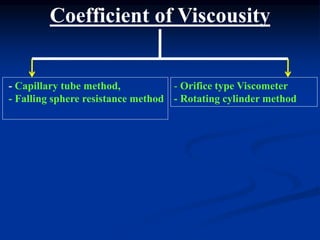

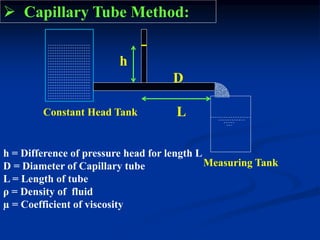

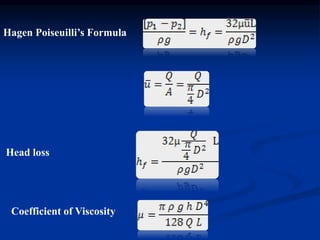

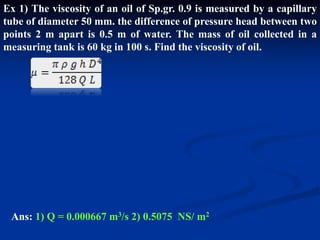

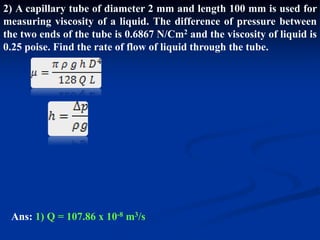

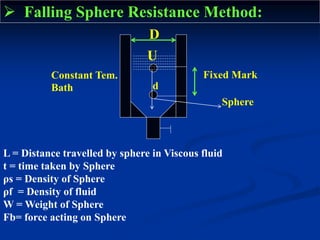

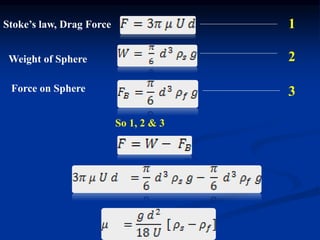

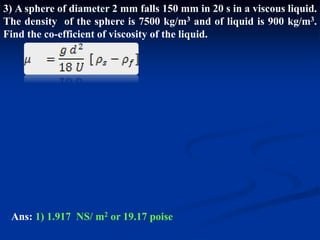

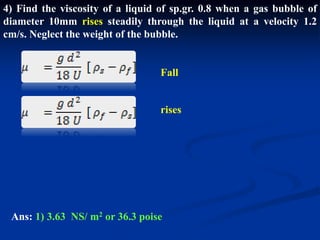

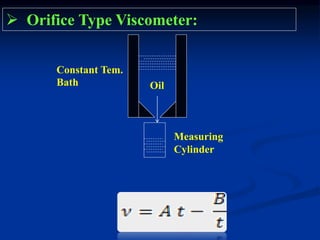

The document discusses fluid dynamics, focusing on the flow of viscous fluids through pipes and between parallel plates, detailing equations such as Hagen-Poiseuille for laminar flow and Darcy-Weisbach for head loss due to friction. It includes various methods for measuring viscosity, including capillary tube and falling sphere resistance methods, along with examples and calculations of pressure drop, shear stress, and average velocity. Additionally, it covers specific problems related to flow rates and pressure gradients for different fluids and pipe configurations.