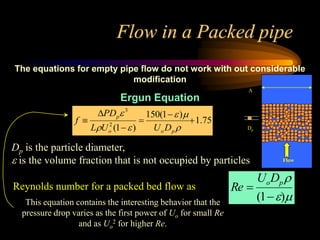

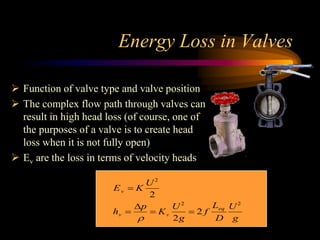

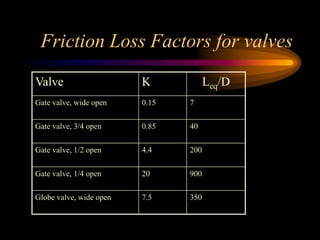

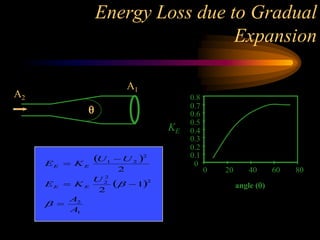

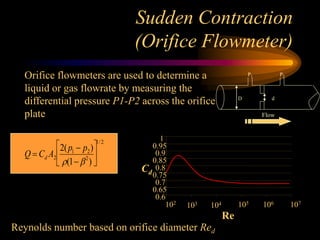

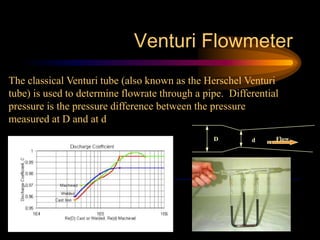

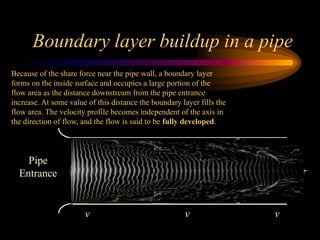

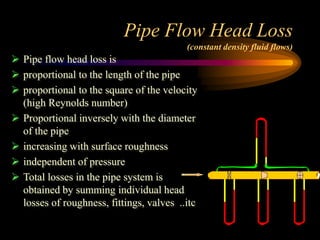

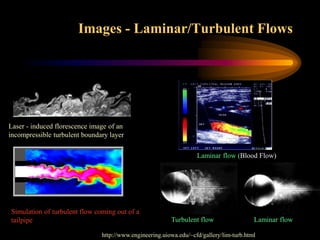

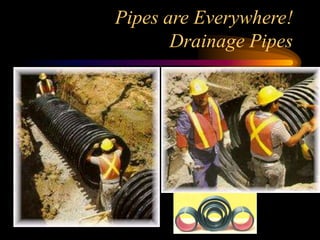

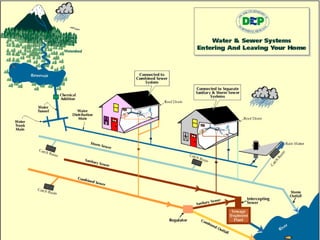

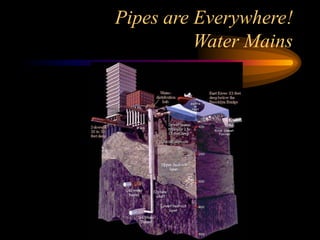

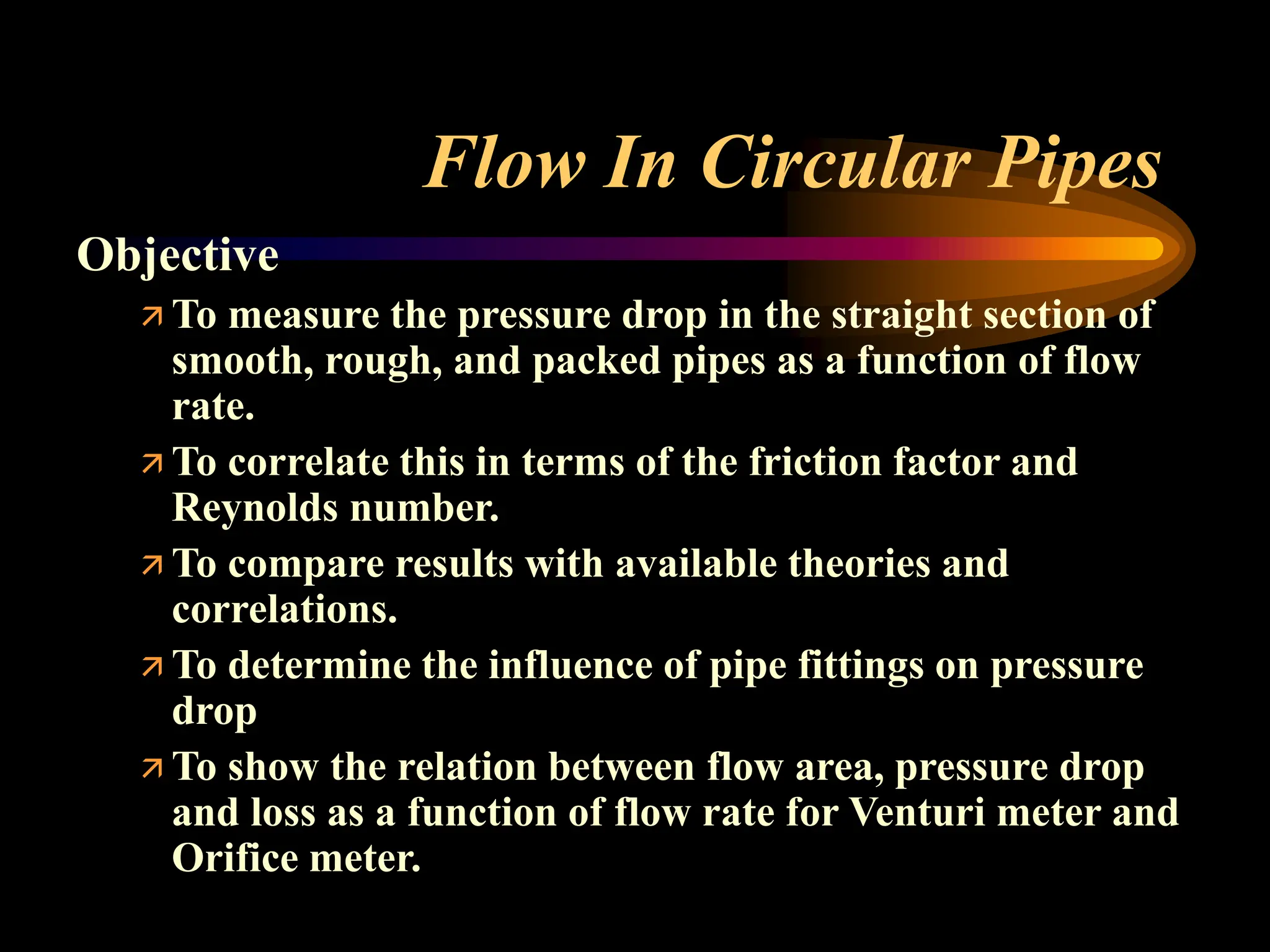

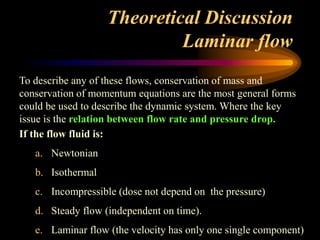

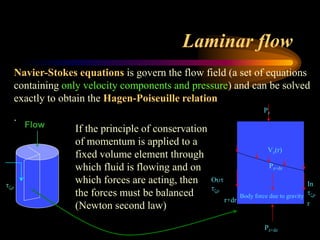

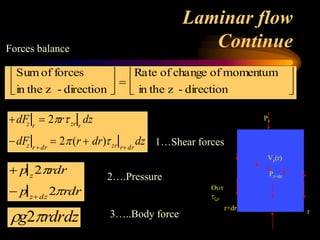

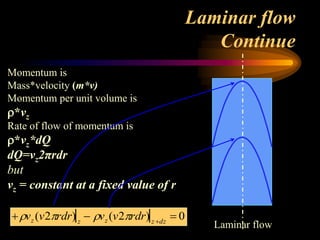

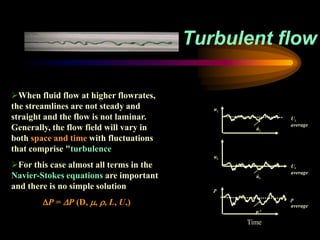

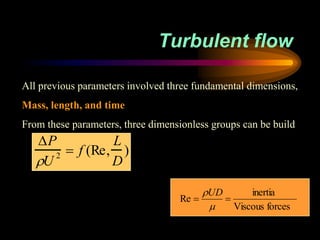

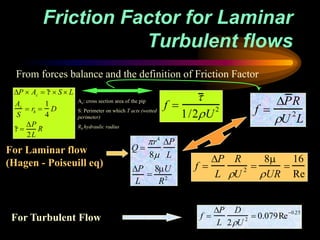

The document discusses flow in circular pipes. It outlines the objectives of measuring pressure drop in smooth, rough and packed pipes as a function of flow rate. It aims to correlate these measurements in terms of friction factor and Reynolds number. The apparatus used includes pipe networks, rotameters and manometers. Laminar and turbulent flow are examined theoretically using concepts like boundary layers, velocity profiles, friction factors and Reynolds number. Flow in valves, expansions, contractions and venturi/orifice meters is also analyzed. Head losses are shown to depend on length, velocity, diameter and roughness. Pipes are ubiquitous in nature, infrastructure and engineering systems.

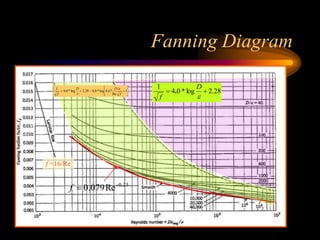

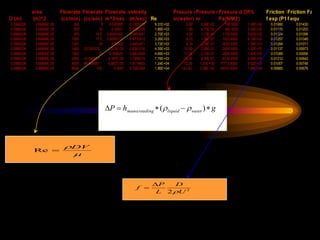

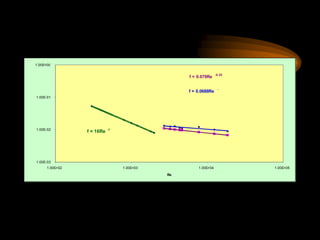

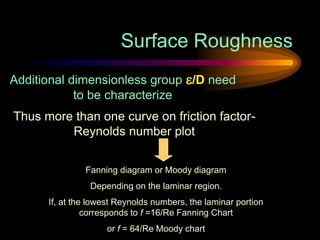

![Friction Factor for Smooth, Transition,

and Rough Turbulent flow

1

f

4.0 * log Re* f

0.4

Smooth pipe, Re>3000

1

f

4.0 * log

D

2.28

Rough pipe, [ (D/)/(Re√ƒ) <0.01]

1

f

4.0*log

D

2.28 4.0*log 4.67

D/

Re f

1

Transition function

for both smooth and

rough pipe

f

P

L

D

2U2

f 0.079Re0.25](https://image.slidesharecdn.com/flowinpipe-231013085012-960b0d6e/85/Flowinpipe-ppt-15-320.jpg)