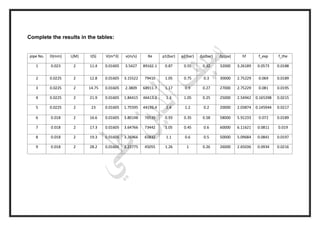

The document outlines an experiment conducted at Baghdad University to measure friction loss along pipes of various diameters and flow rates, aiming to compare experimental results of the Darcy-Weisbach coefficient with theoretical values. It details the apparatus used, theoretical background on pressure loss and friction factor calculations, and a step-by-step experimental procedure. Results and discussions explore the relationship between Reynolds number and friction factor, as well as the impact of diameter changes on head loss.