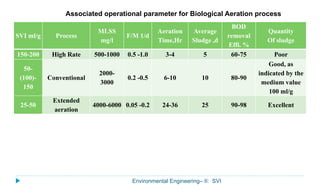

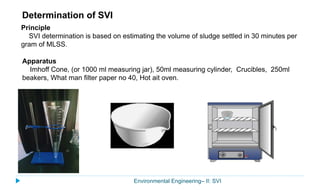

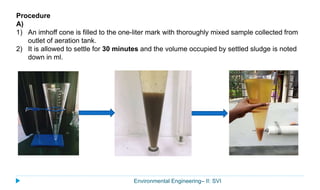

This document provides information about the Sludge Volume Index (SVI), which is used to monitor the efficiency of aeration systems in activated sludge wastewater treatment processes. SVI is determined by measuring the volume in ml occupied by 1 gram of mixed liquor sample after allowing it to settle for 30 minutes. SVI values indicate the type of process and quality of sludge. A SVI over 200 ml/g indicates bulking sludge, which is undesirable. The document outlines the procedure to determine SVI in a lab and discusses factors that influence SVI values such as plant design, operations, and influent wastewater characteristics.

![Environmental Engineering– II: SVI

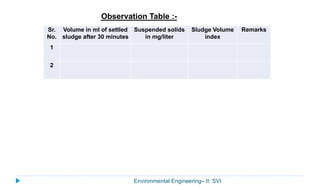

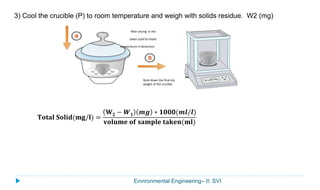

6) The filtrate is evaporated to dryness in hot air oven for about eight hour at 1030 to1050c. It is

then allowed to cool in desiccator & weighed accurately (W4)

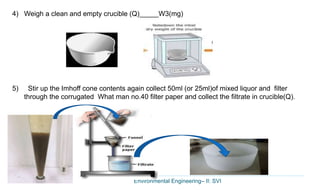

Dissolved 𝐒𝐨𝐥𝐢𝐝(𝐦𝐠/𝐥) =

𝐖 𝟒

−𝑾 𝟑

𝒎𝒈 ∗𝟏𝟎𝟎𝟎(𝒎𝒍/𝒍)

𝐯𝐨𝐥𝐮𝐦𝐞 𝐨𝐟 𝐬𝐚𝐦𝐩𝐥𝐞 𝐭𝐚𝐤𝐞𝐧(𝐦𝐥)

Mixed Liquor Suspended Solids (MLSS) = MLTS – MLDS

SVI, ml/g = [V (ml/l) ×1000(mg/g)] / MLSS (mg/g)]](https://image.slidesharecdn.com/svi-201103102824/85/Sludge-Volume-Index-SVI-12-320.jpg)