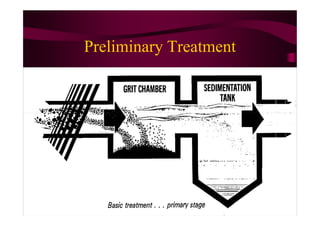

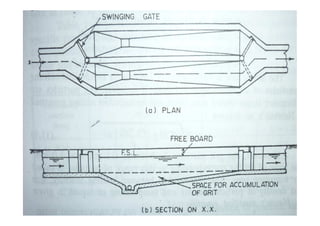

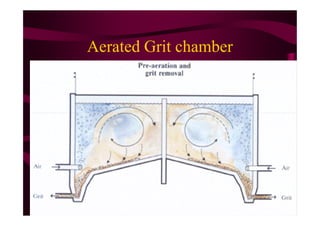

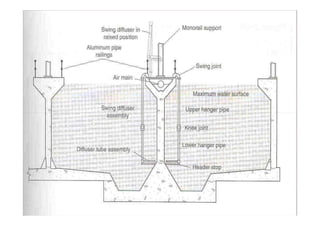

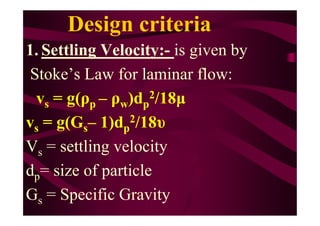

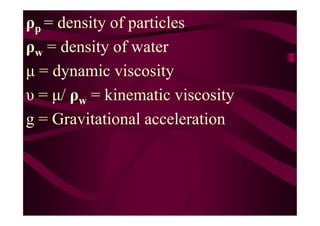

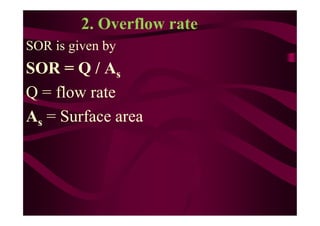

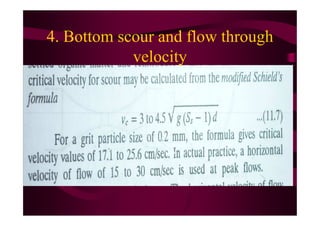

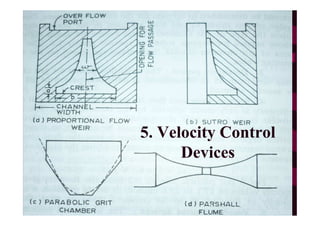

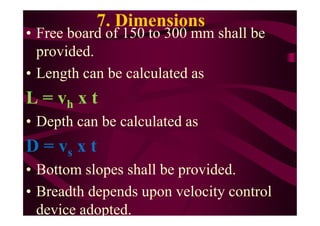

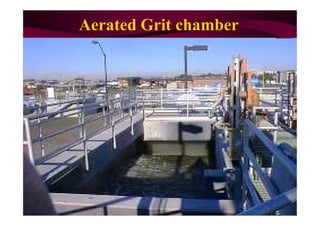

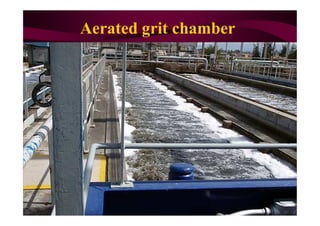

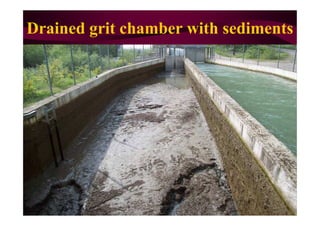

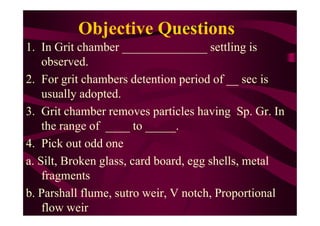

Grit chambers are sedimentation basins designed to remove inorganic particles such as sand and gravel before sewage enters finer screening processes. They can be mechanically or manually cleaned and include horizontal and aerated types, with specific design criteria for settling velocity, overflow rate, and dimensions. The collected grit is often disposed of through washing, filling low-lying areas, or incineration, and requires a defined detention period for effective operation.