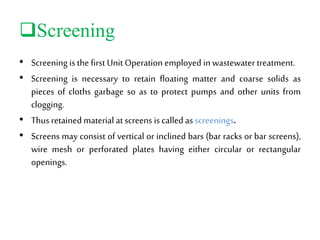

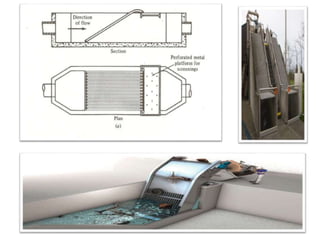

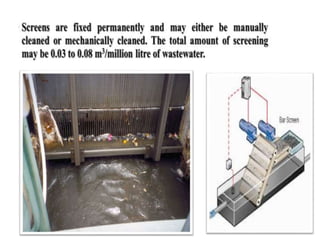

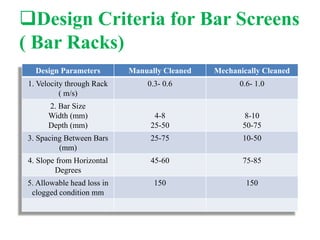

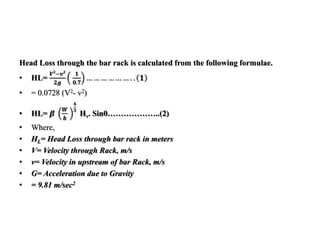

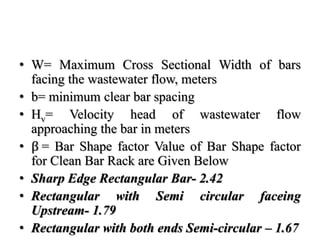

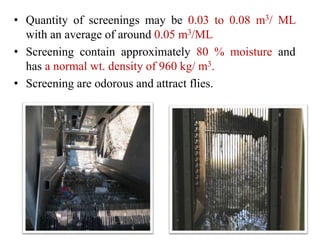

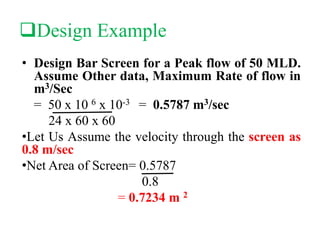

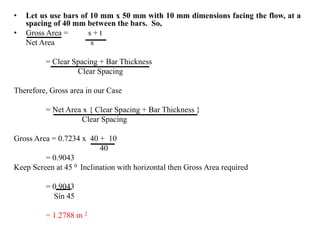

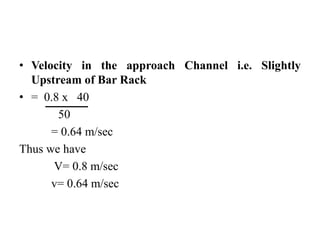

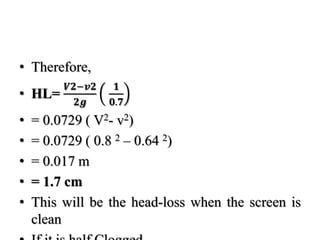

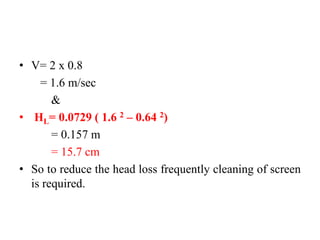

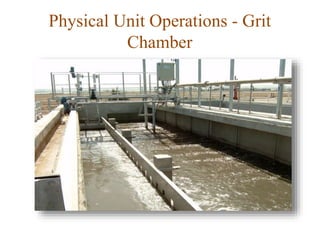

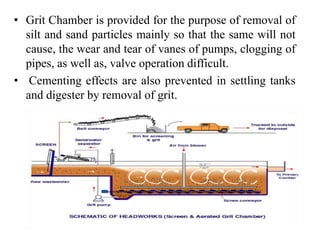

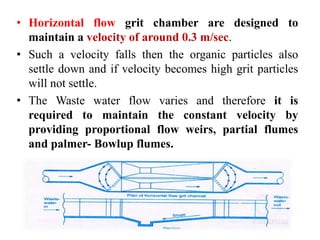

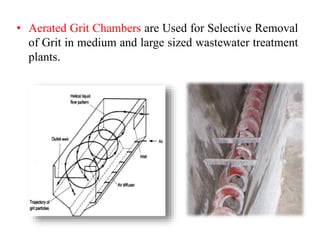

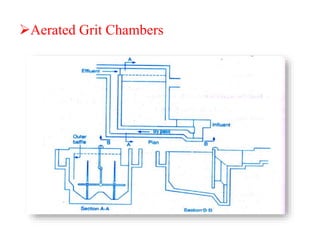

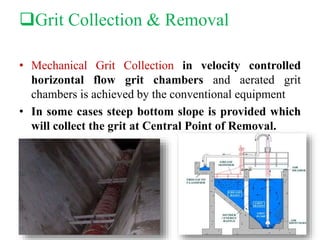

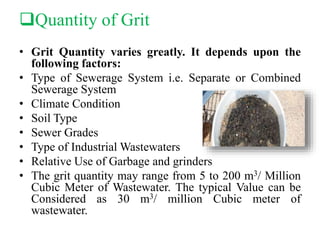

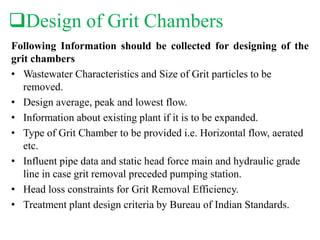

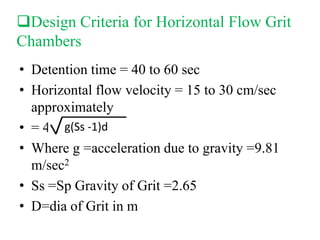

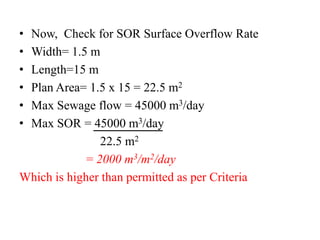

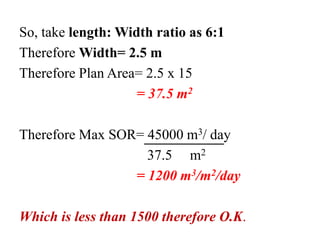

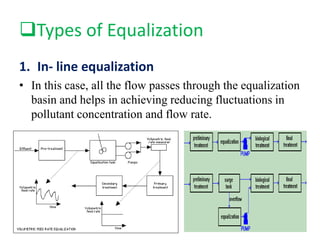

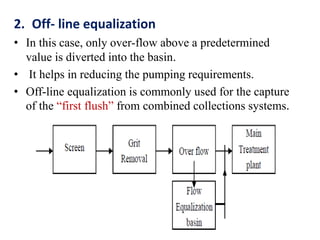

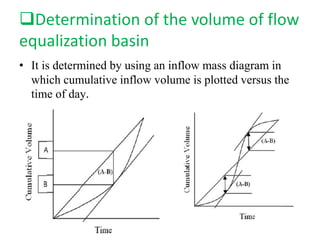

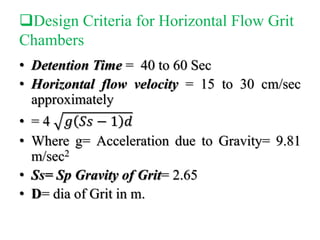

This document provides information on physical unit operations for wastewater treatment including screening, grit removal, and equalization. It discusses the design criteria and processes for bar screens, grit chambers, and flow equalization basins. Screening is the first step and removes large solids to protect equipment. Grit chambers use reduced velocities to settle out sand and grit. Equalization basins dampen flow variations by storing flow to provide a constant rate to downstream processes. Design considerations for each include sizing, velocities, detention times, and removal efficiencies based on wastewater flow rates and characteristics.