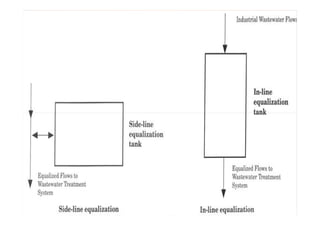

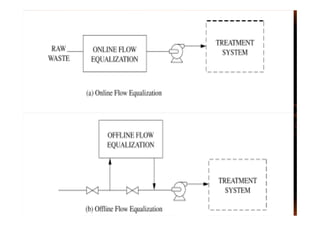

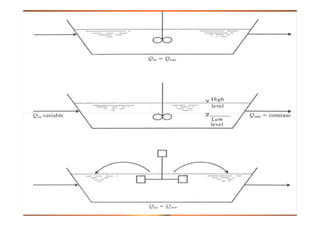

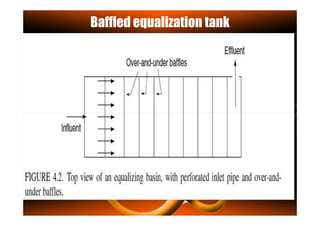

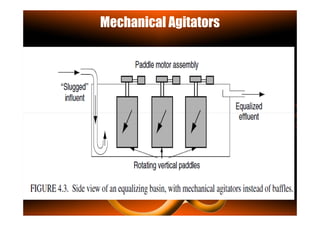

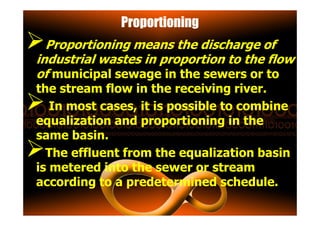

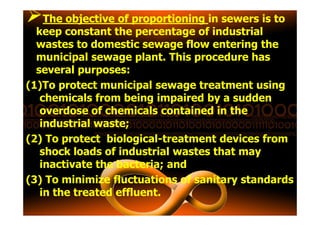

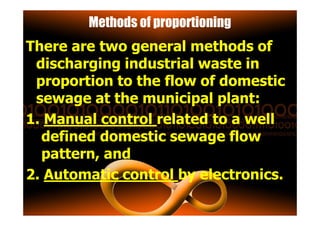

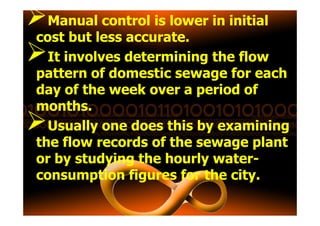

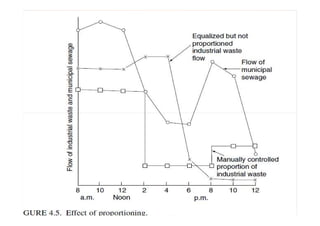

The document discusses the importance of equalization and proportioning in industrial wastewater treatment, stating that they help deliver a constant and manageable quantity and quality of waste to receiving environments. Equalization minimizes fluctuations in wastewater characteristics, while proportioning ensures that industrial waste is discharged in proportion to domestic sewage flow. Effective equalization methods include in-line and side-line systems, with various techniques for mixing waste to facilitate treatment.

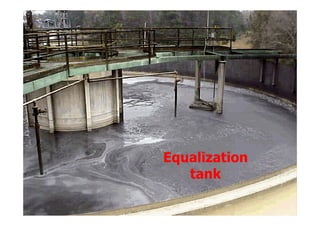

![Equalization is a method of

retaining waste in a basin so that

the effluent discharged is fairly

uniform in its water qualityuniform in its water quality

characteristics (pH, color,

turbidity, alkalinity, biochemical

oxygen demand [BOD], and so

forth).](https://image.slidesharecdn.com/l-8equalizationandproportioning-150311205130-conversion-gate01/85/L-8-equalization-and-proportioning-4-320.jpg)