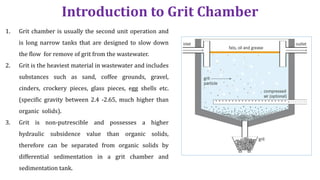

- Grit chambers are used to remove grit (heavy inorganic solids like sand and gravel) from wastewater to protect equipment.

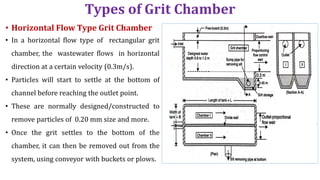

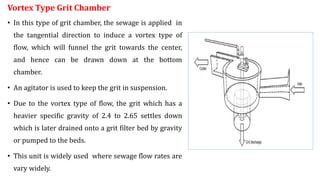

- There are three main types of grit chambers: horizontal flow, aerated, and vortex. Horizontal flow uses gravity settling, aerated uses air to create spiral flow, and vortex uses tangential inflow to induce a vortex.

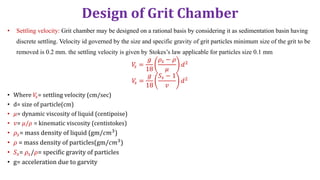

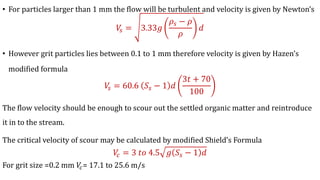

- Grit chamber design considers the settling velocity and size of grit particles. Parameters like detention time, number of units, flow velocity, and loss of head are also designed.

- Cleared grit is collected manually or mechanically, then disposed of through dumping, burying, or landfilling. Odorous grit should be buried.