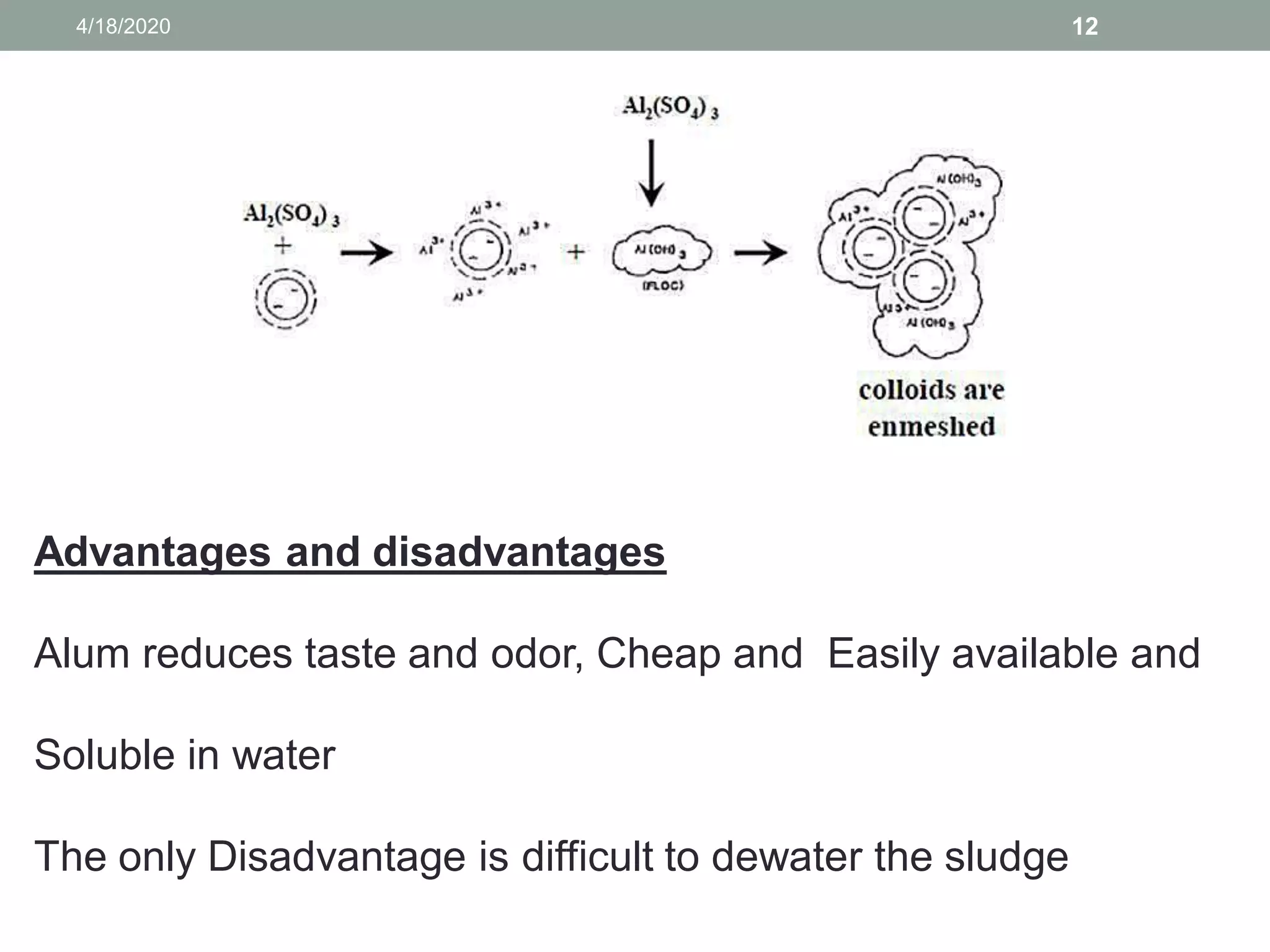

The document covers the principles and processes of coagulation and flocculation in water treatment, focusing on their mechanisms, types of coagulants, and the design of flocculators. It discusses the interactions between colloids, the destabilization process, and various coagulants like aluminum sulfate and ferrous sulfate with their respective advantages and disadvantages. Additionally, it details mixing techniques and design criteria for equipment used in these processes.

![4/18/2020 25

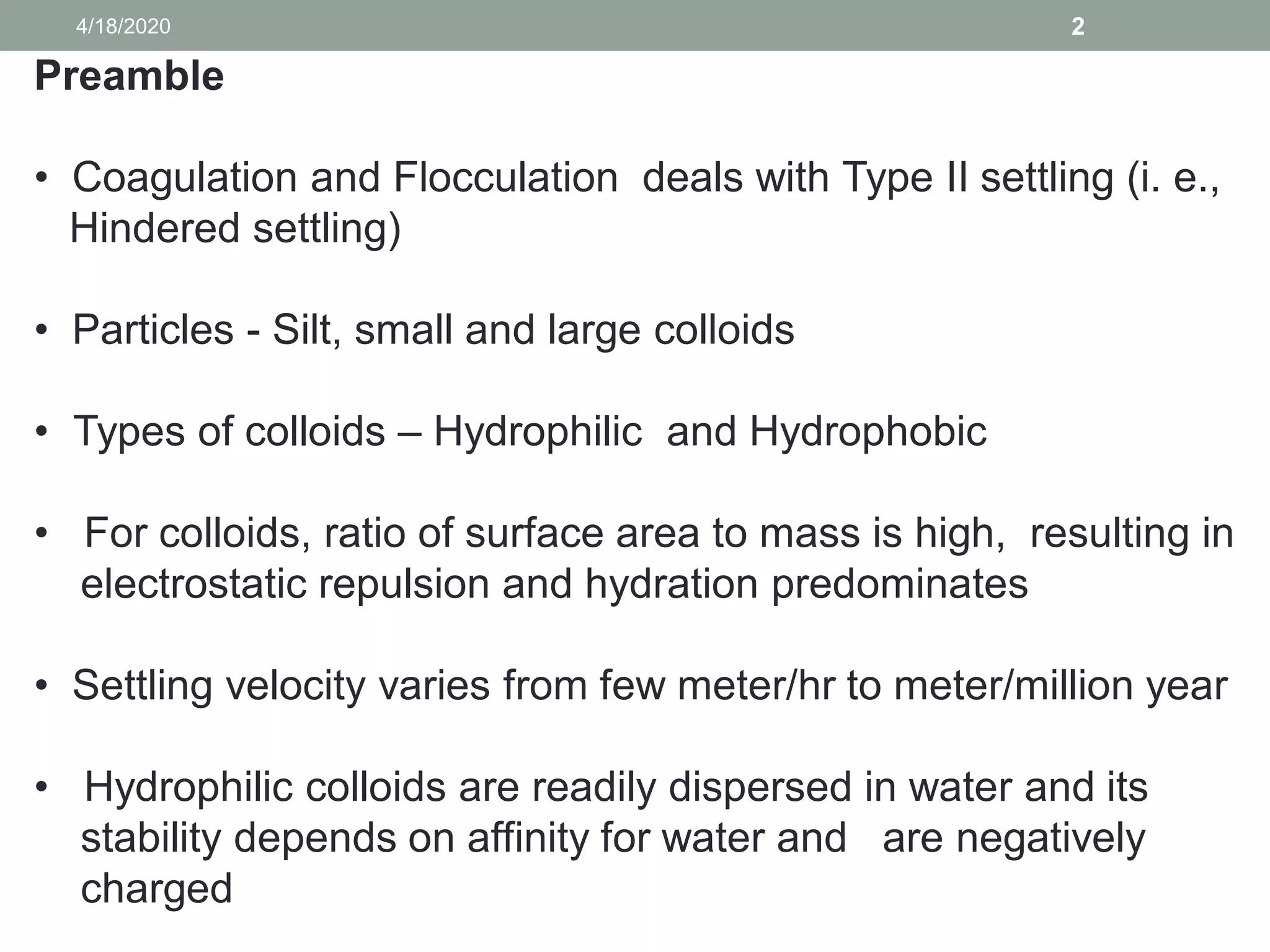

i) Flash mixer (Mixing basin)

• The power input required for mixing is expressed

in terms of temporal mean velocity gradient, G’

• G’ = [ P/µ.V]1/2

G’ = Velocity gradient (per second)

µ = Absolute or dynamic viscosity of water in Ns/m2

V = Volume of water to which P is applied, in m3

The unit of G’ will evidently be 1/s (i.e., per second)](https://image.slidesharecdn.com/coagulation-200418125021/75/Coagulation-aided-Sedimentation-25-2048.jpg)