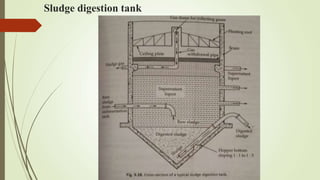

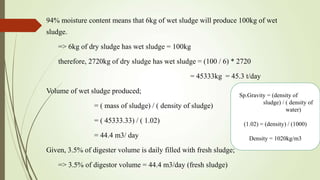

This document discusses the sludge digestion process. It involves three stages: acid fermentation where organic solids are broken down, acid regression where volatile acids are converted, and alkaline fermentation where methane is produced. Key factors that affect digestion are temperature, pH, seeding with digested sludge, and mixing raw and digested sludge. The document also provides an example design for a sludge digestion tank to handle 40,000 people based on sludge production rates and tank sizing calculations.