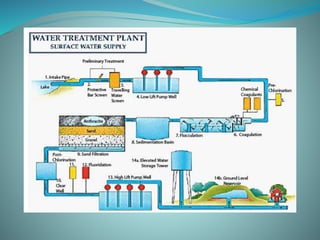

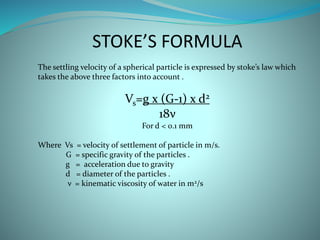

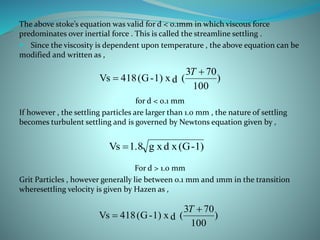

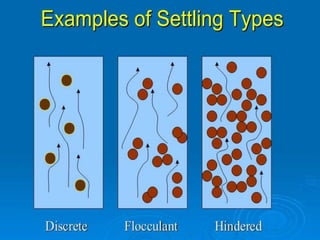

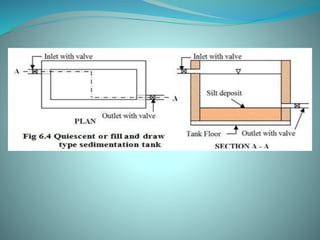

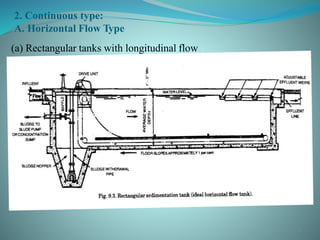

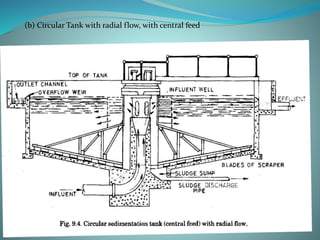

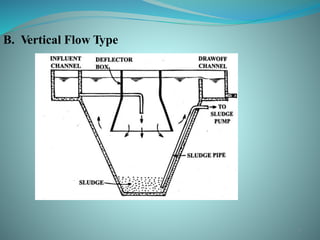

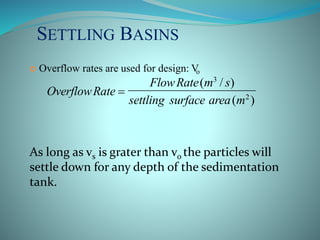

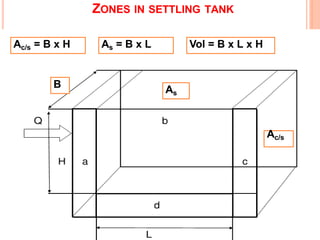

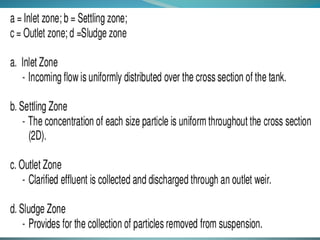

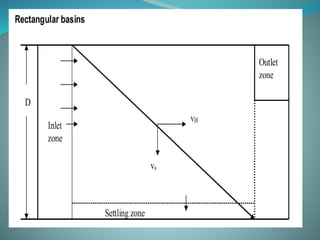

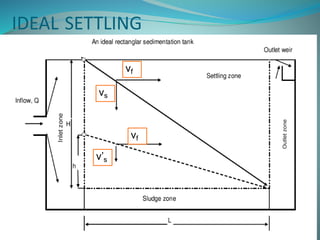

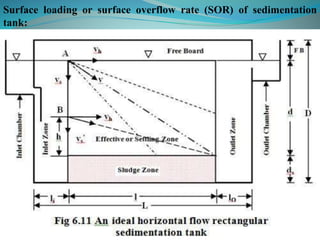

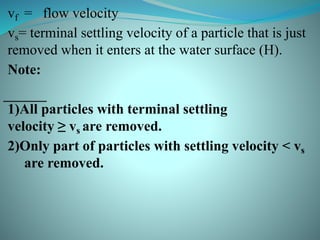

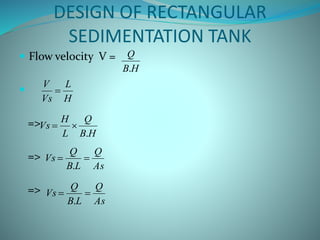

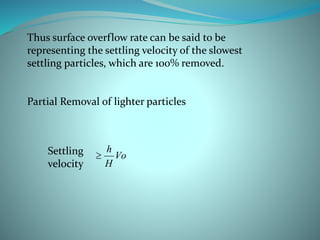

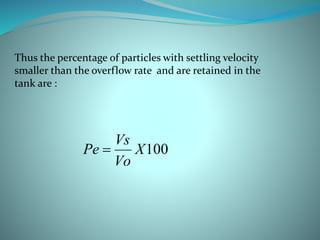

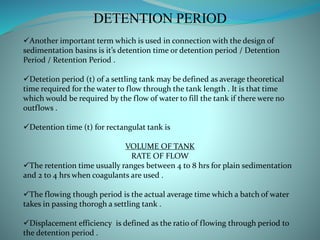

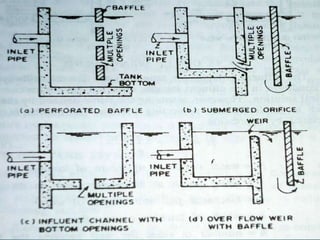

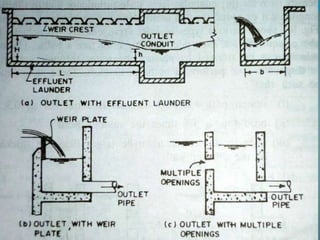

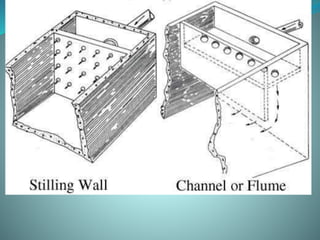

The document discusses sedimentation in water treatment. It defines sedimentation as the gravitational accumulation of solids at the bottom of water. It then discusses factors that affect sedimentation rates such as particle size and shape, water viscosity, and temperature. Stokes' formula and other equations for calculating particle settling velocity are provided. The main types of sedimentation tanks - quiescent/fill and draw, horizontal flow rectangular and circular, and vertical flow - are described. Key design considerations like surface overflow rate and detention period are also summarized. Finally, the need for periodic sludge removal from sedimentation tanks is mentioned.