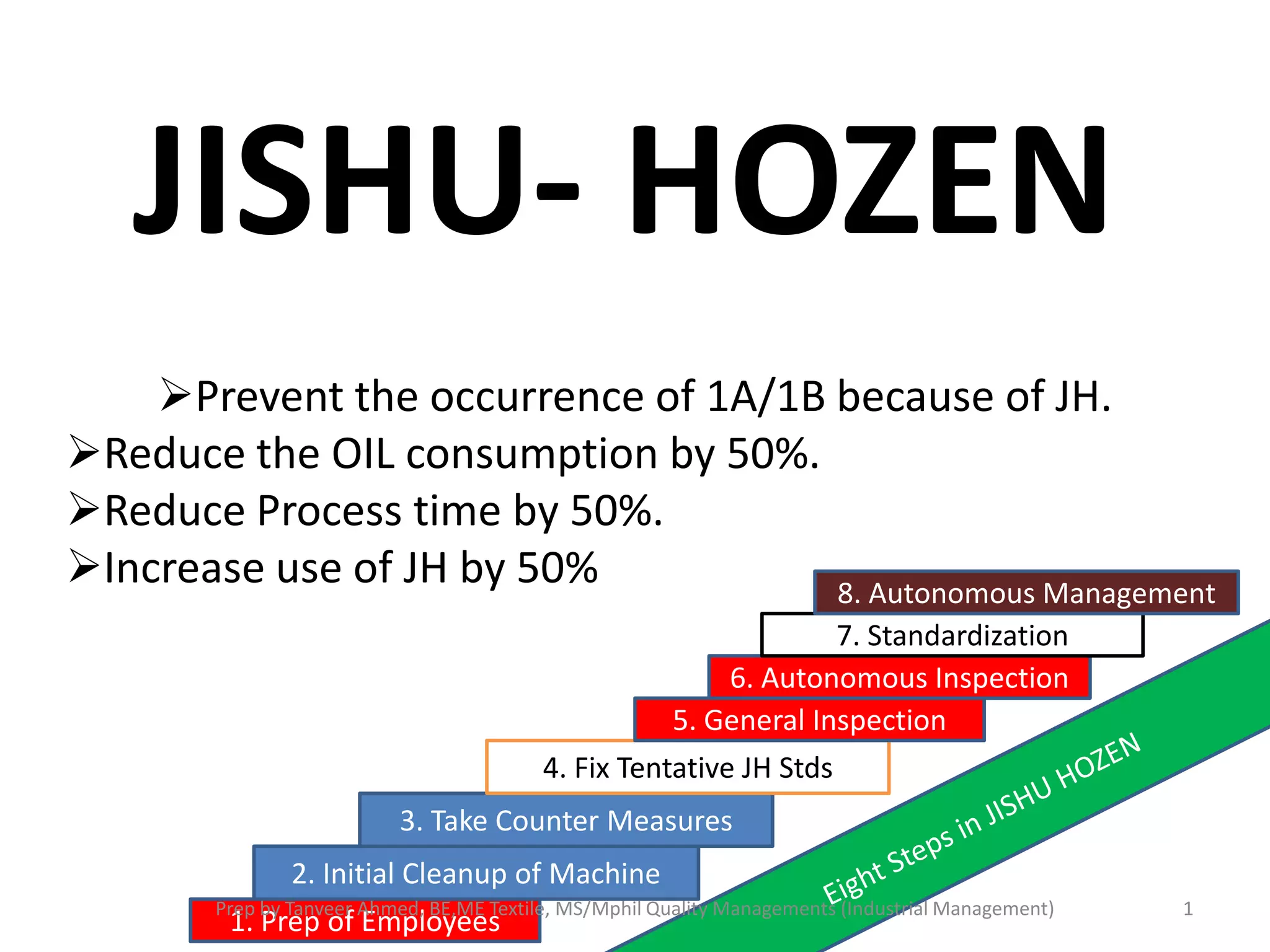

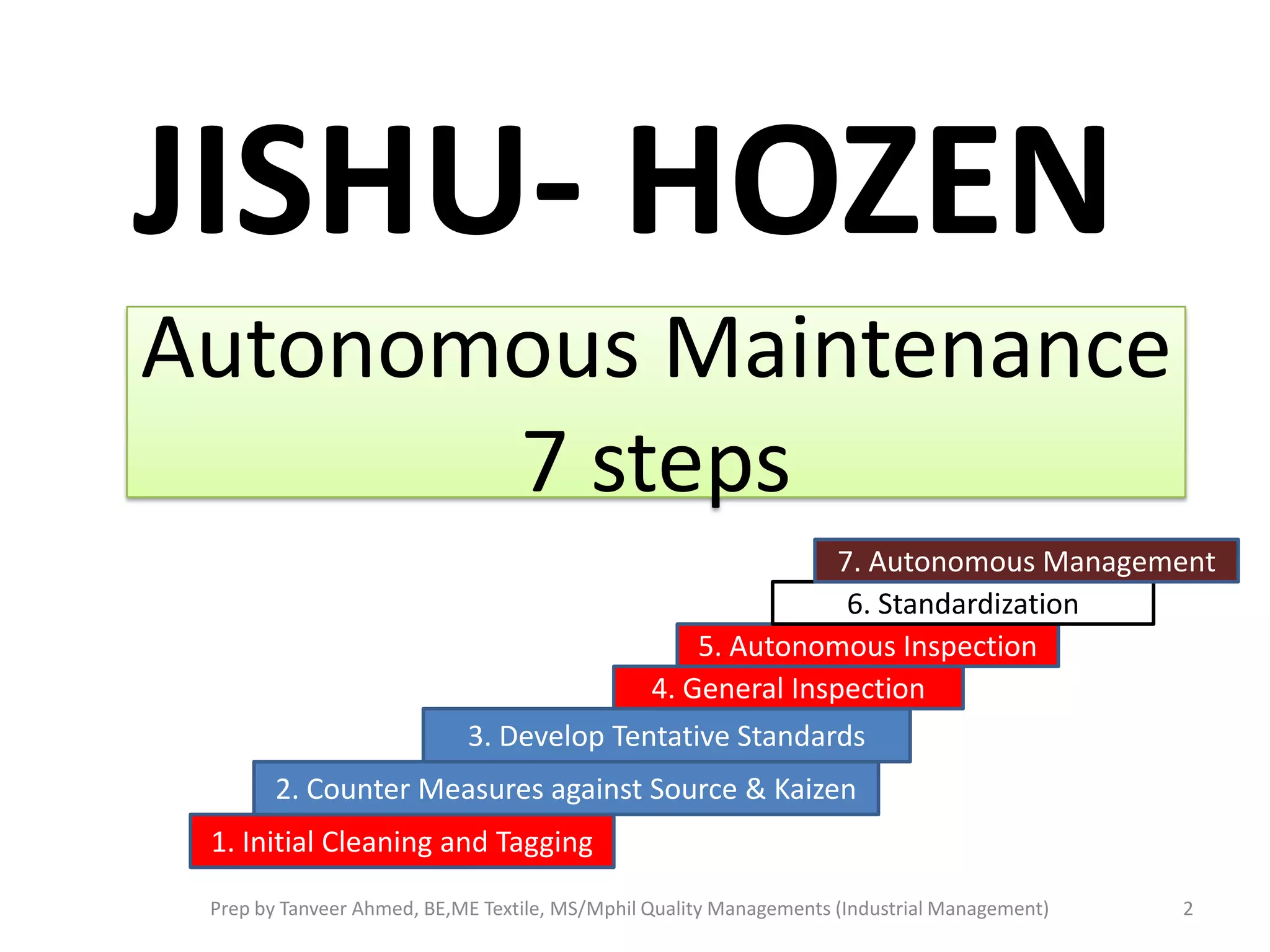

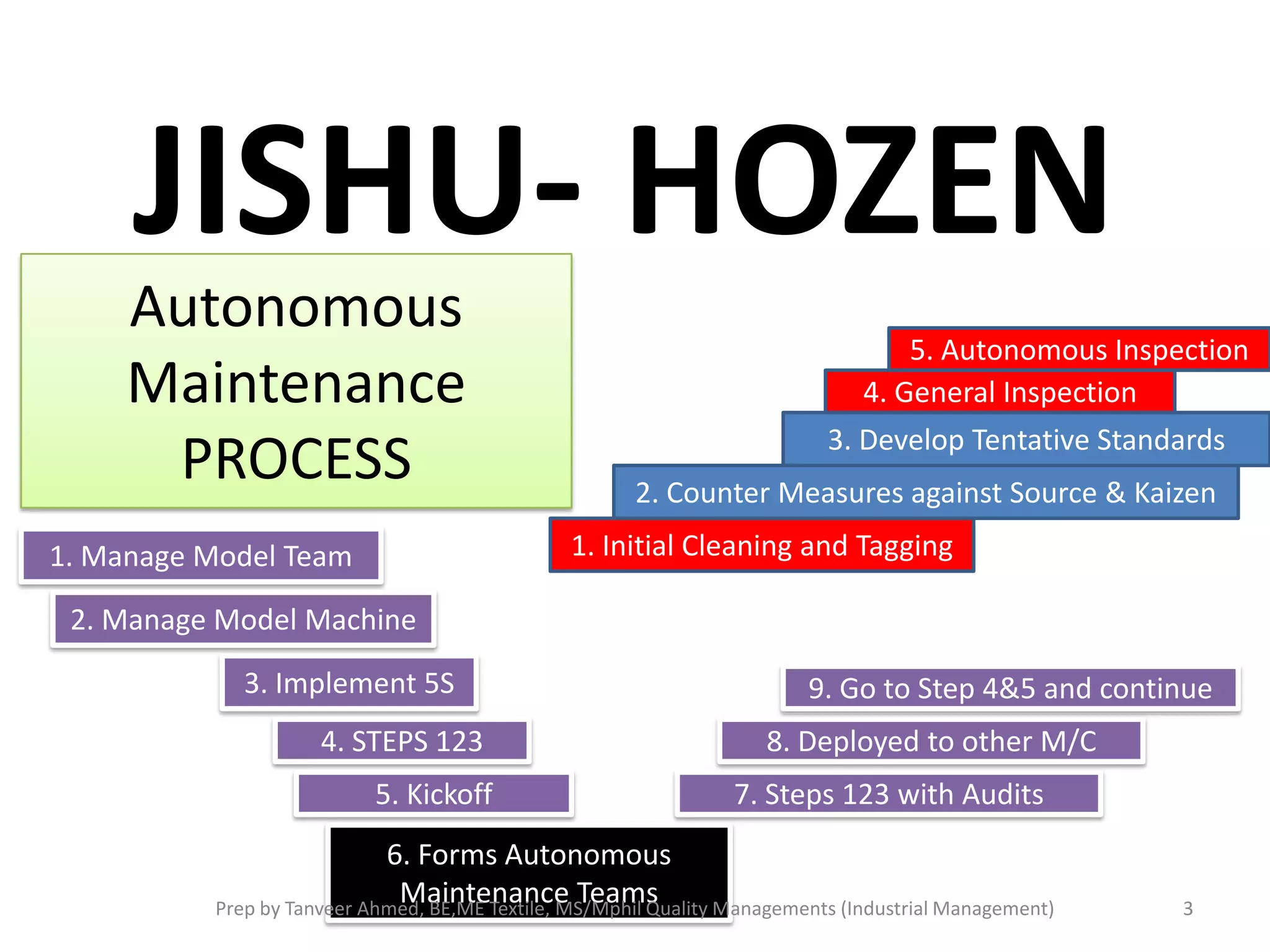

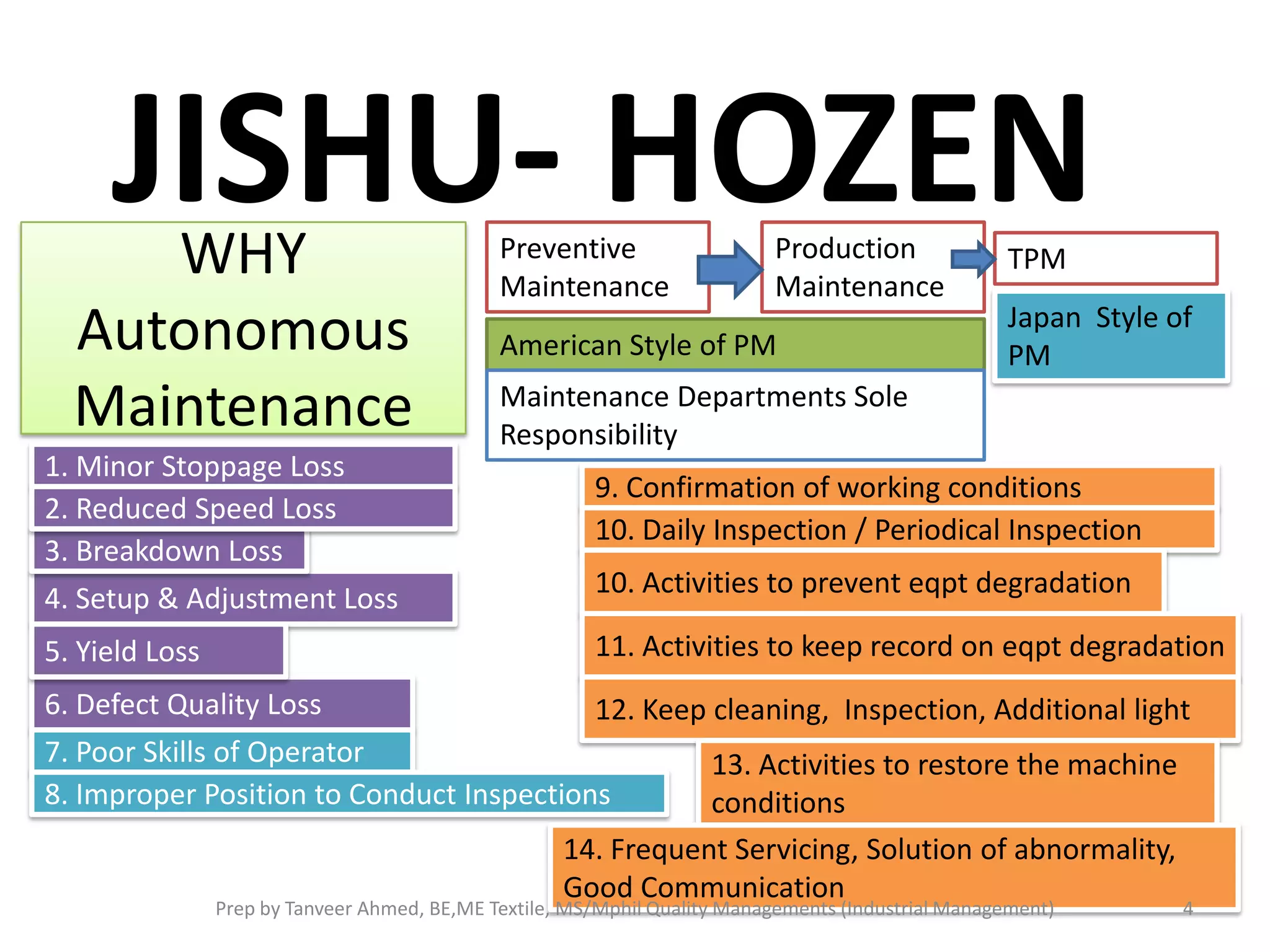

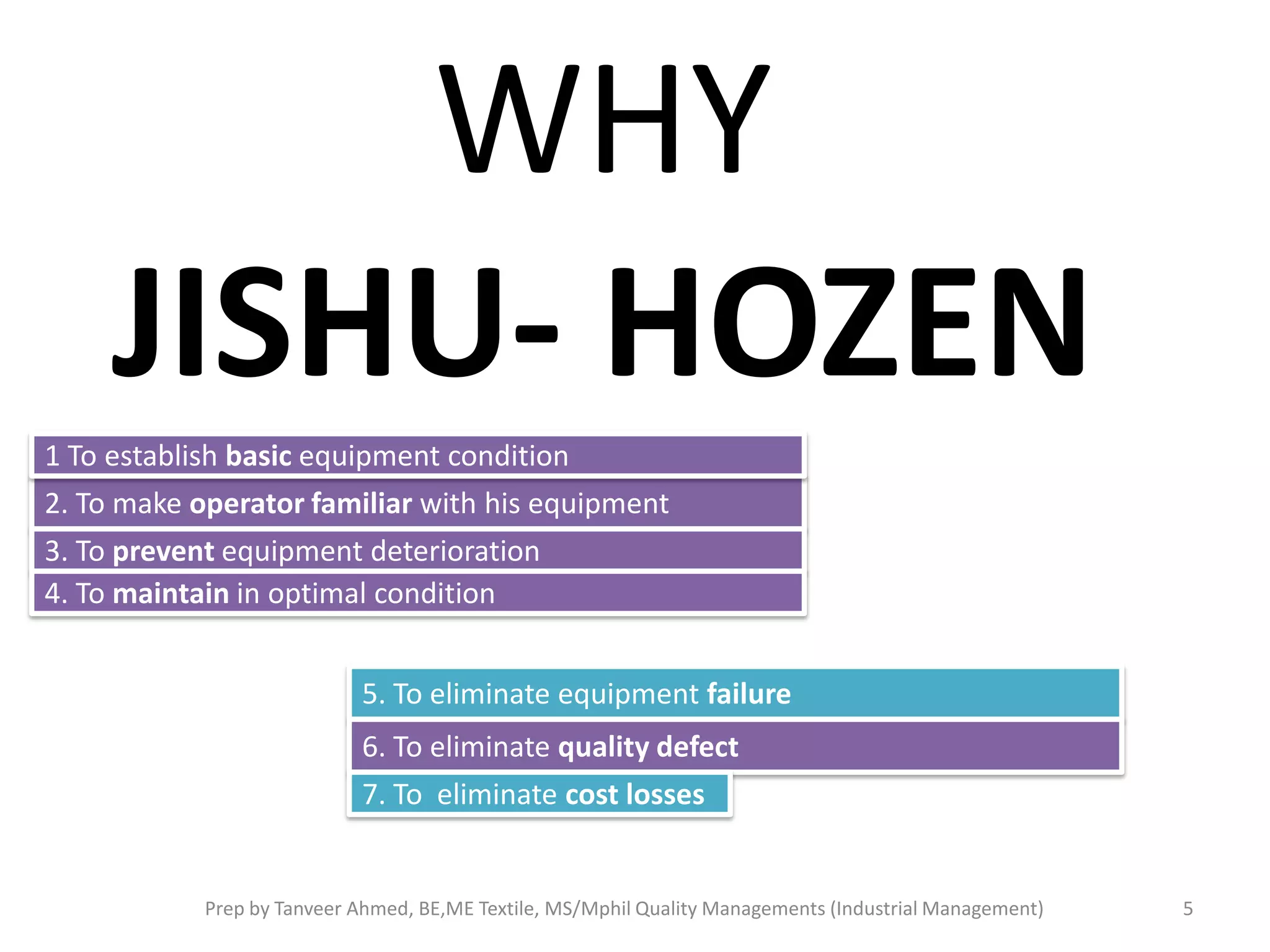

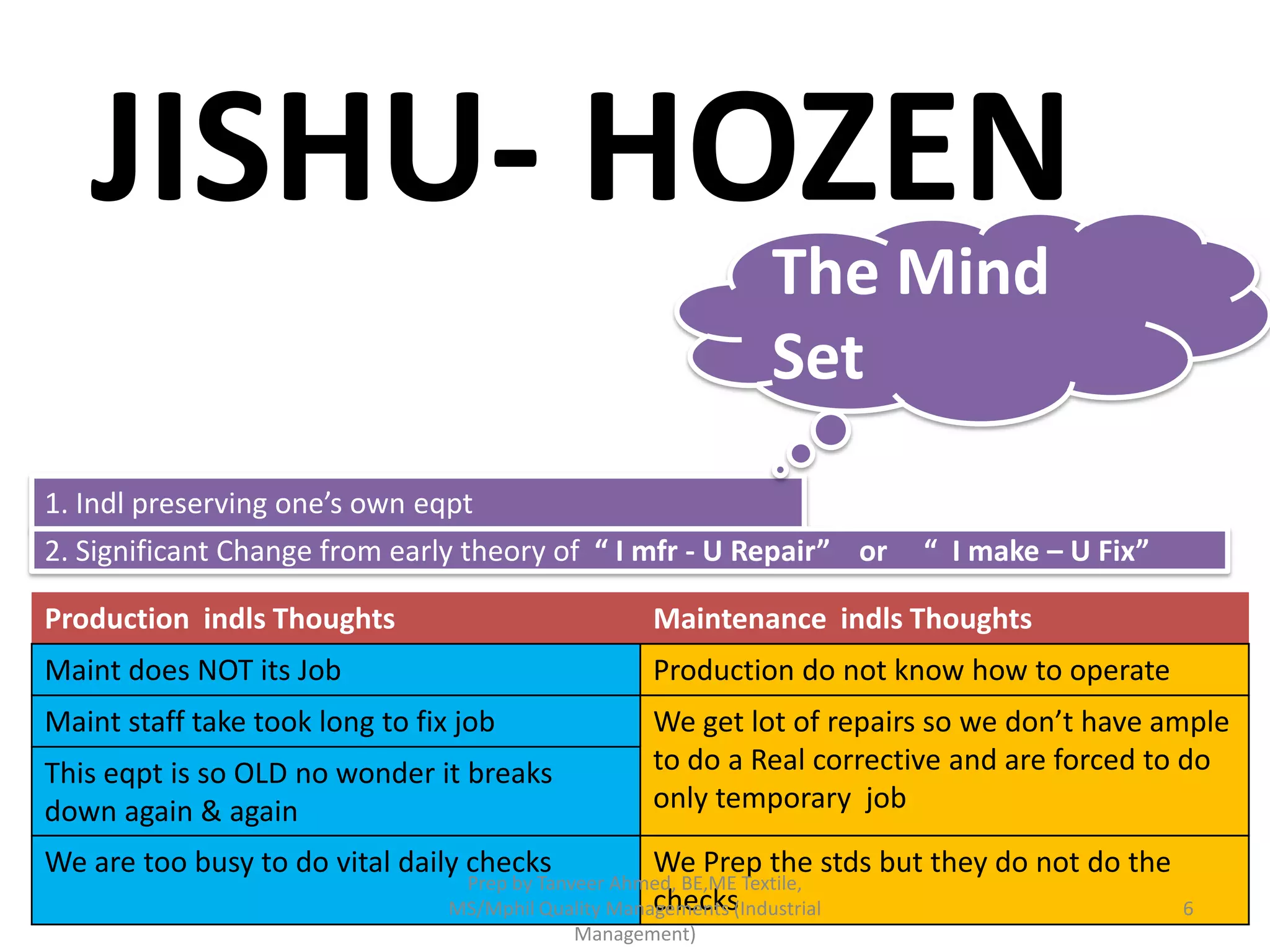

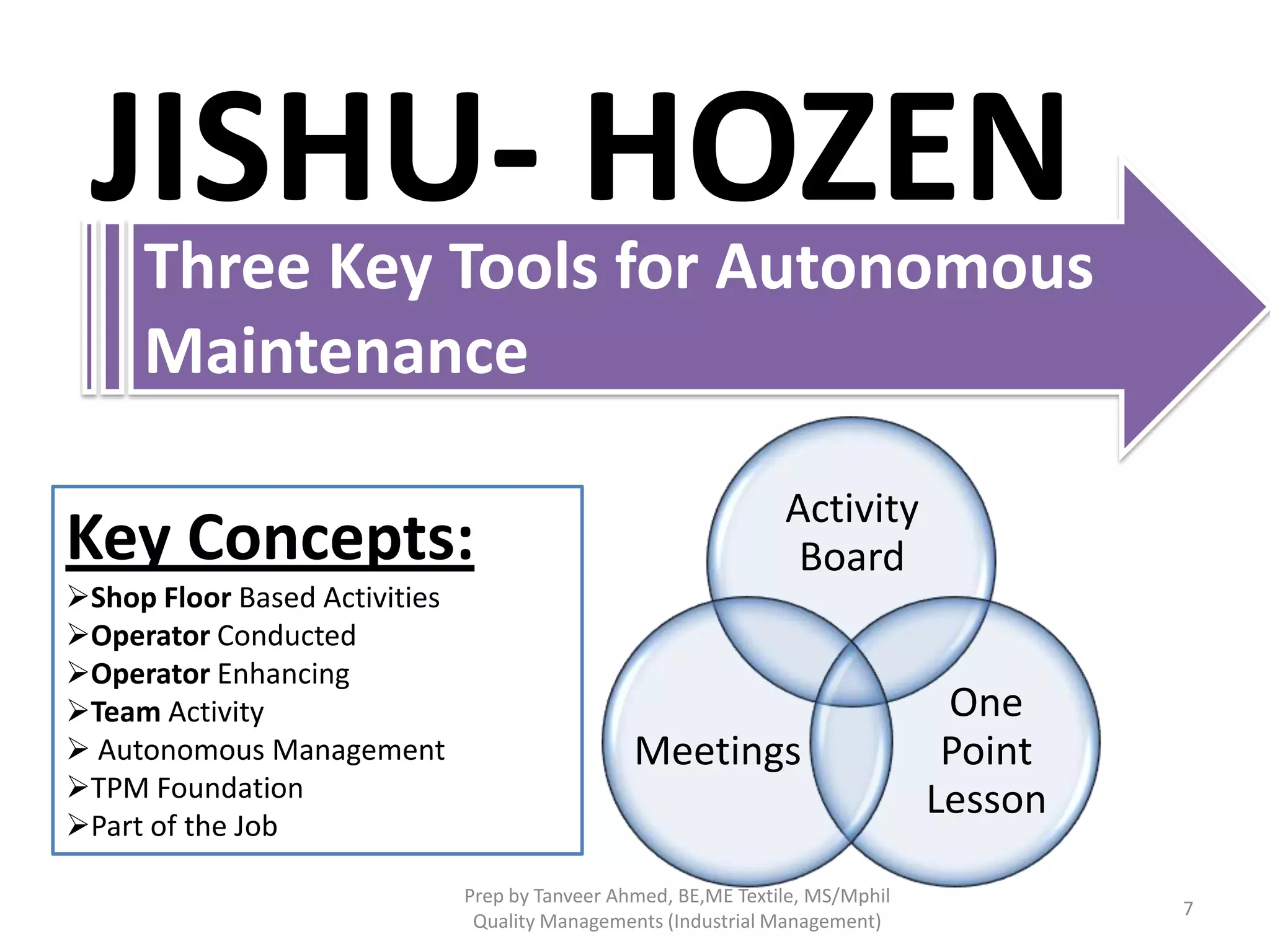

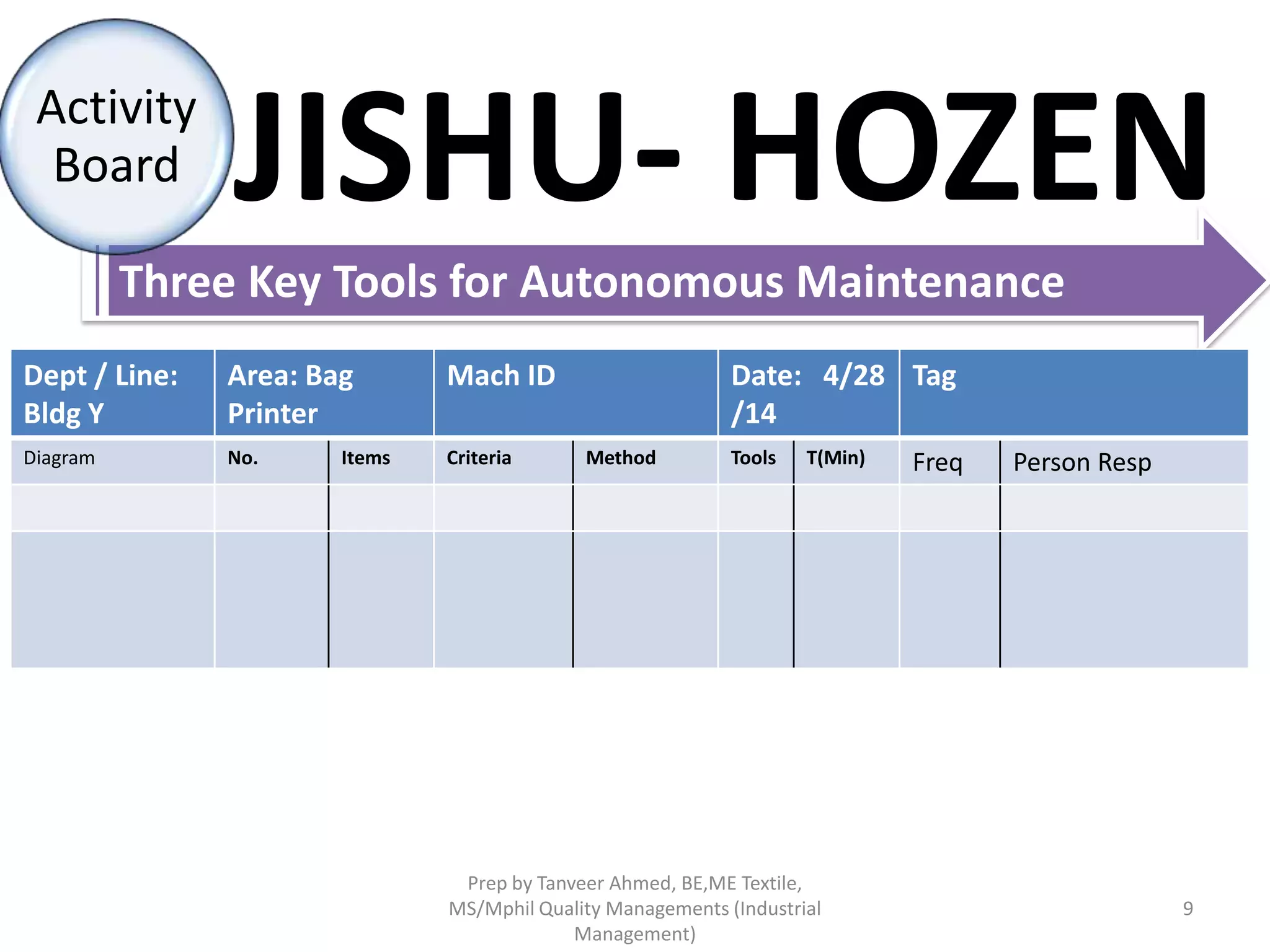

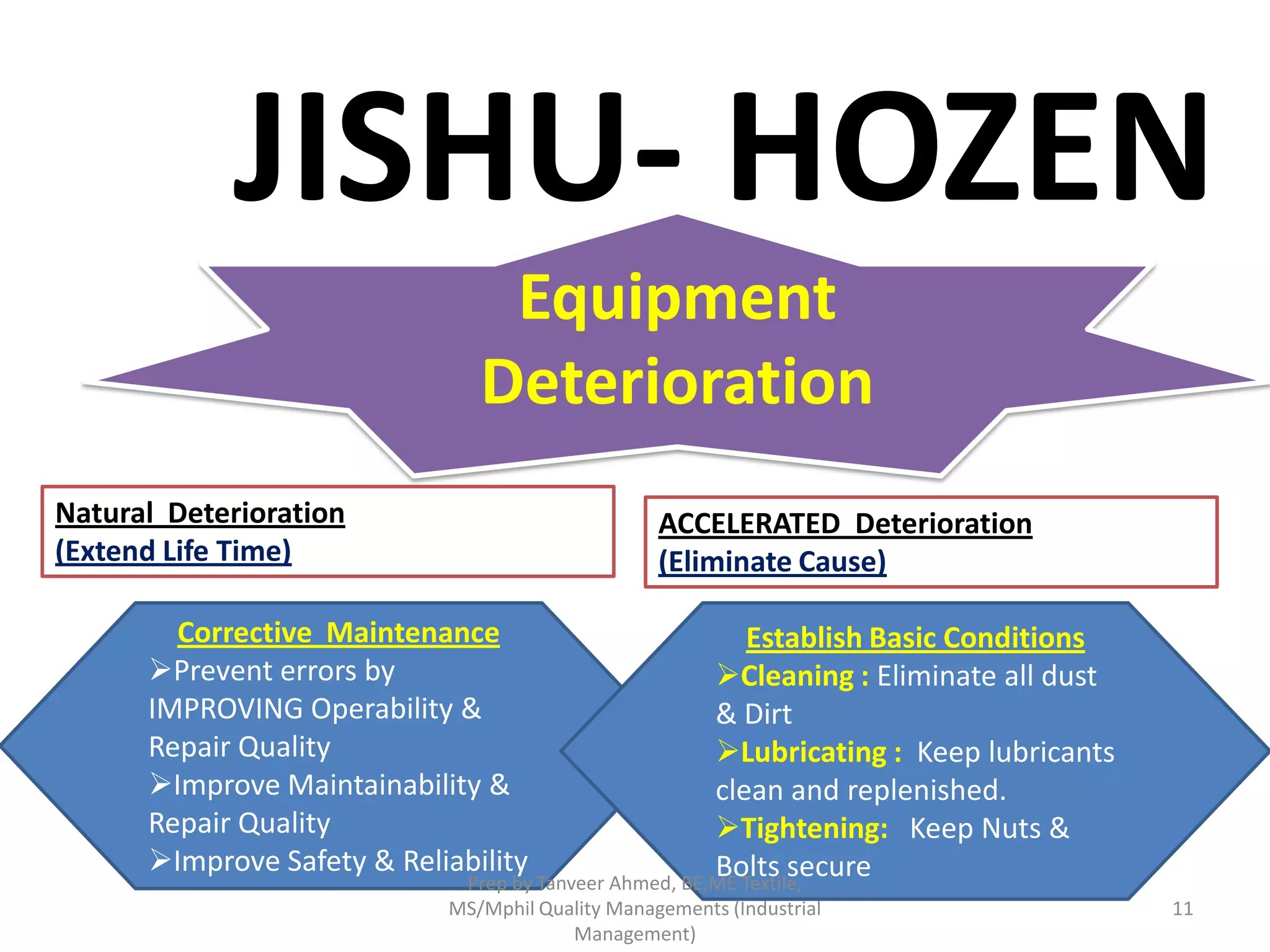

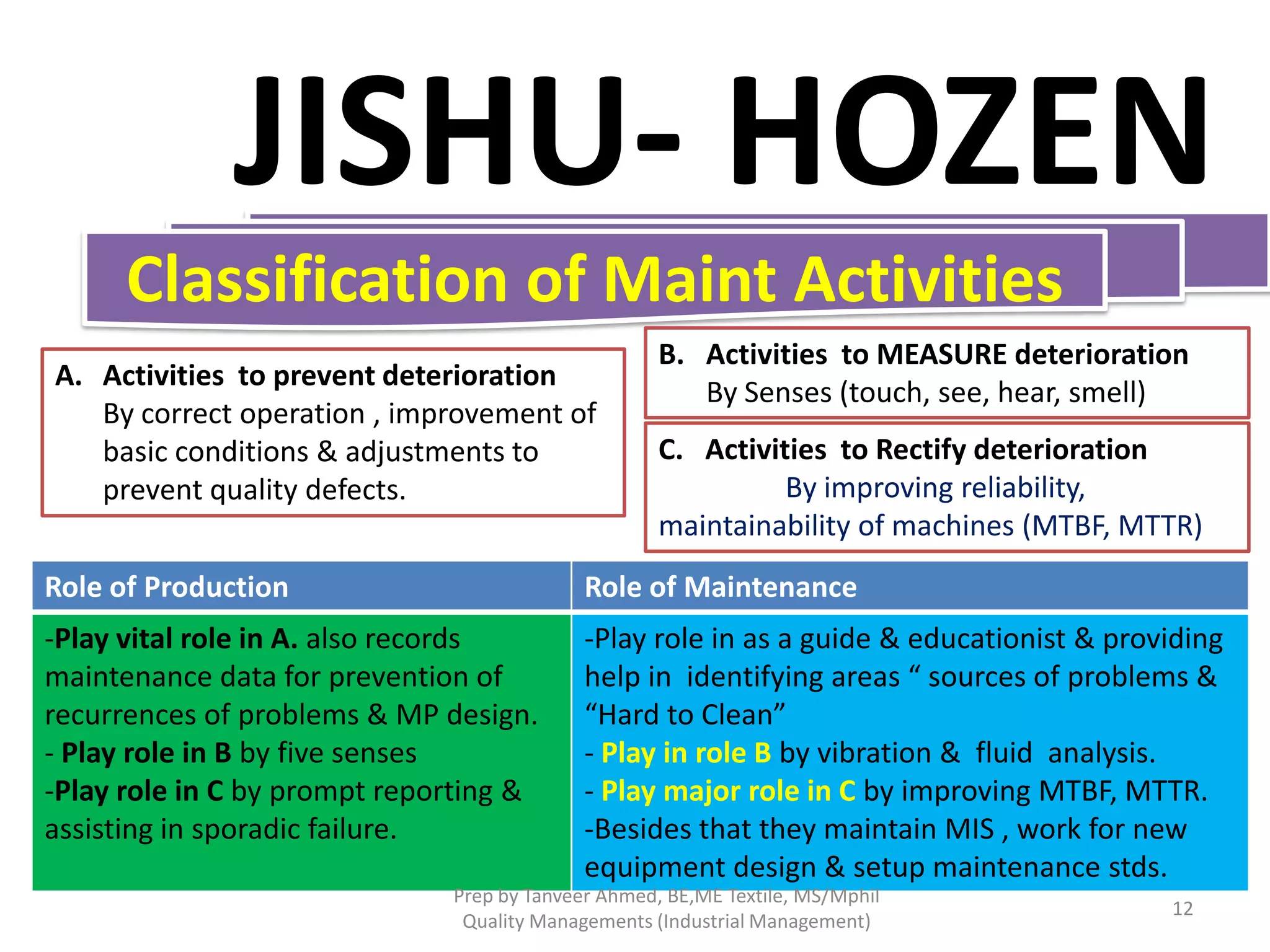

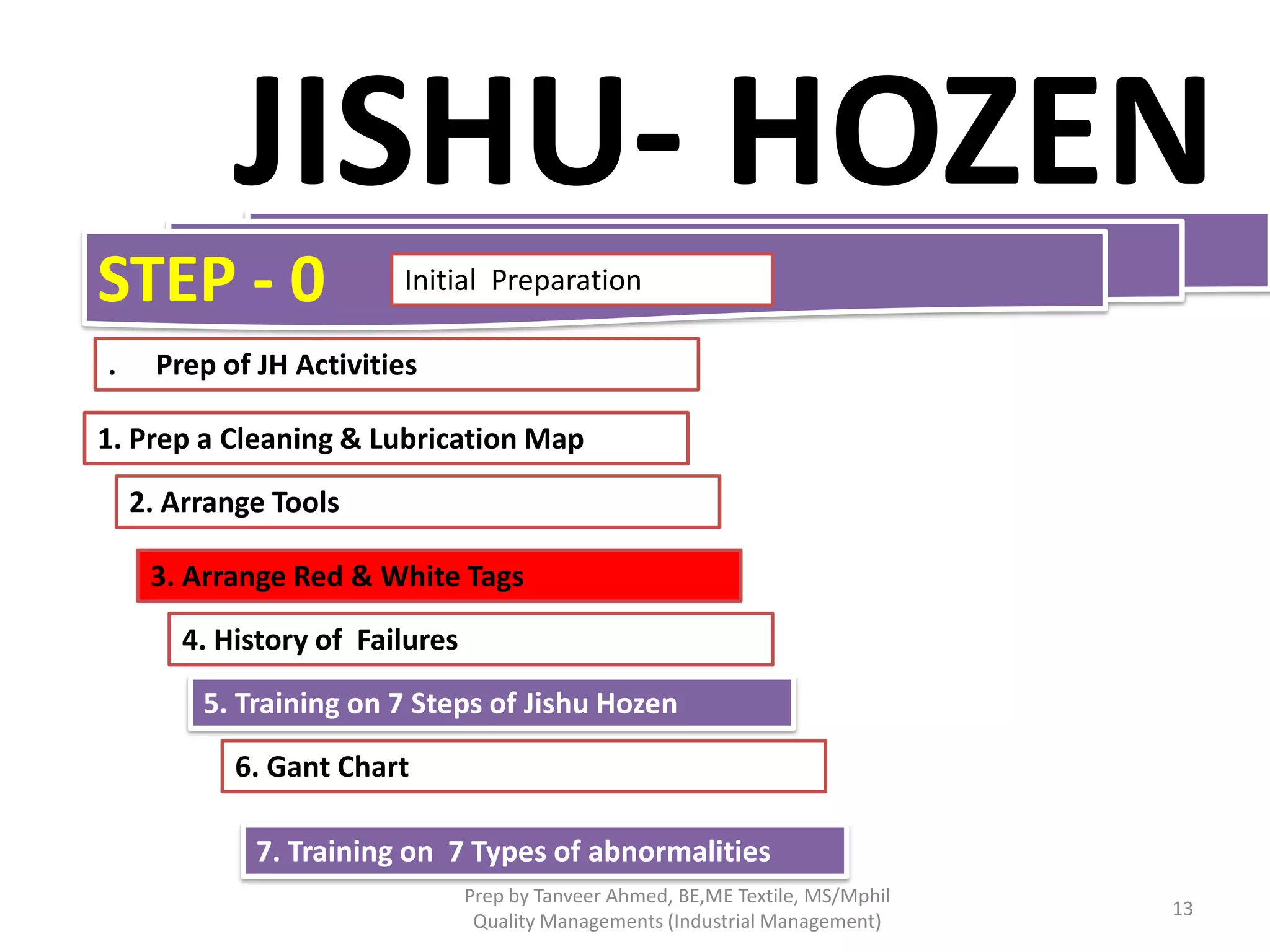

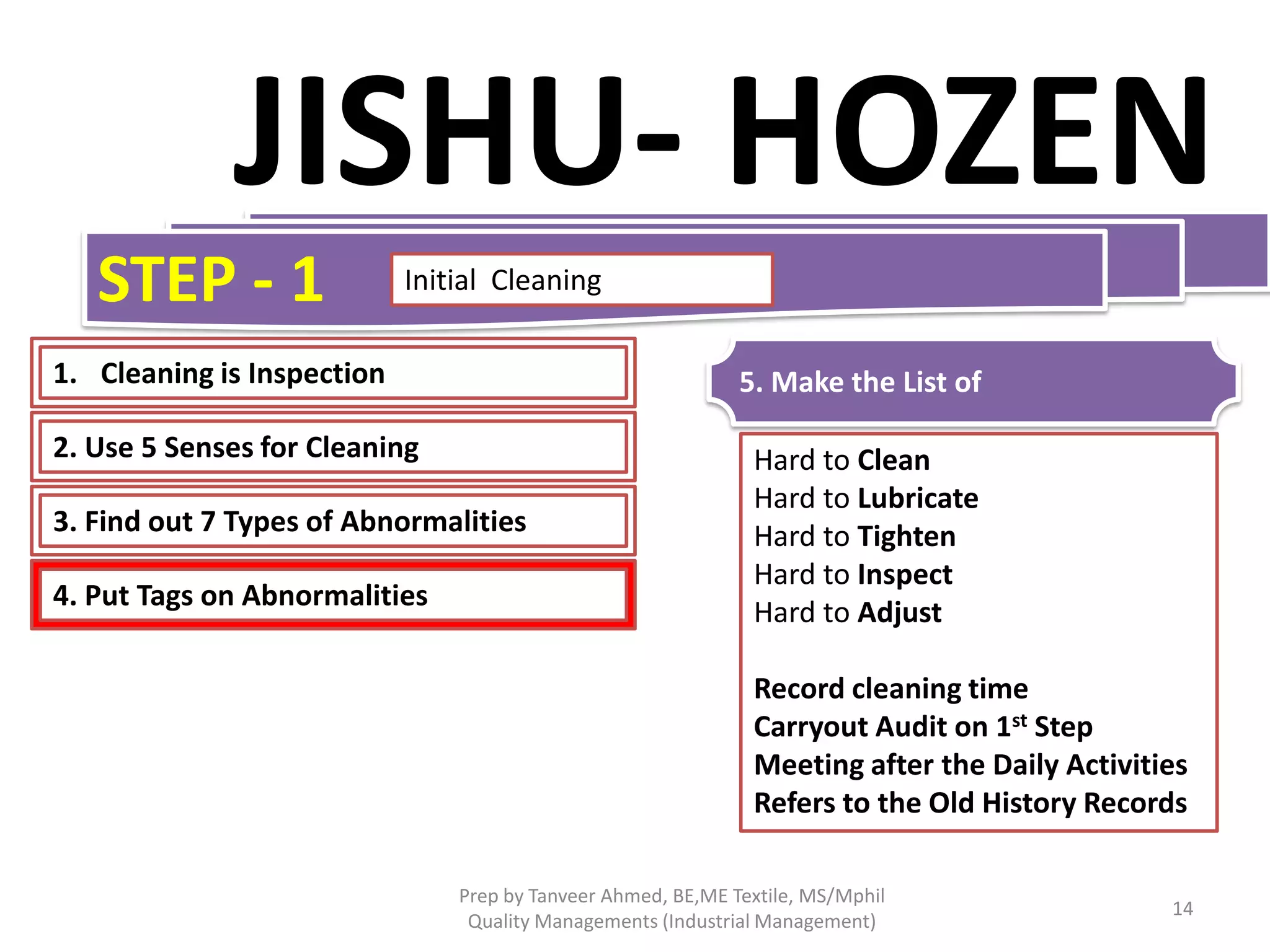

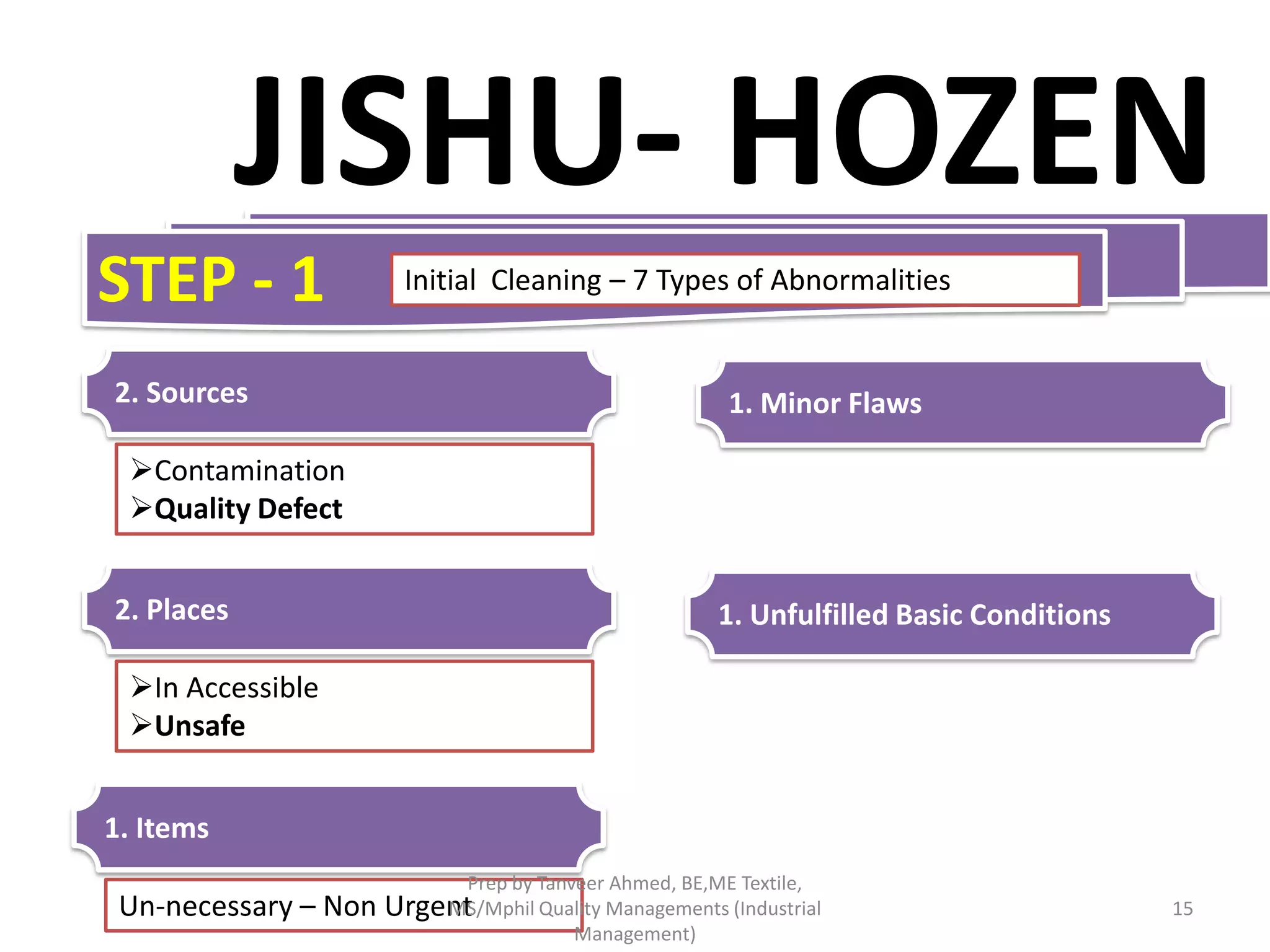

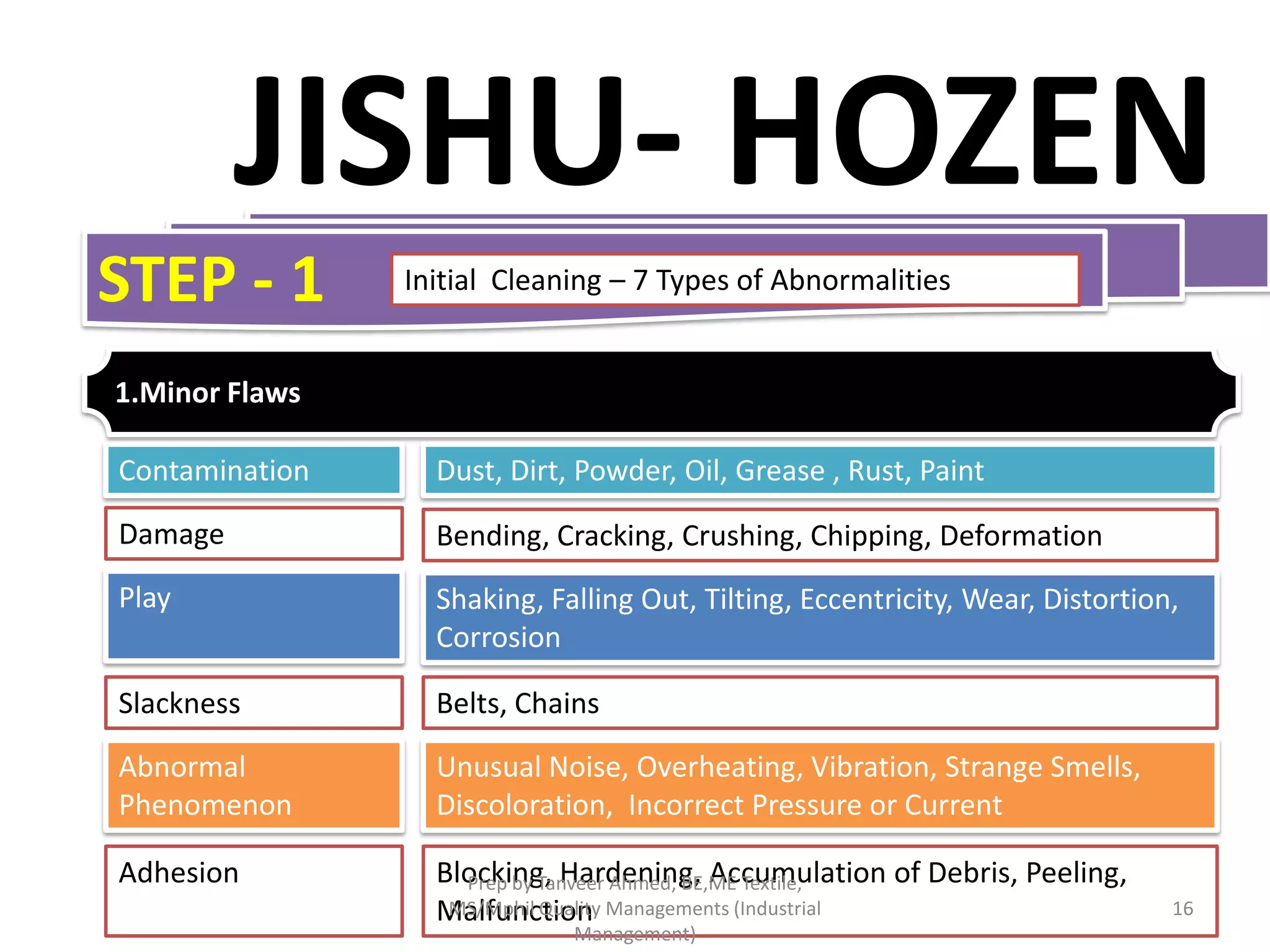

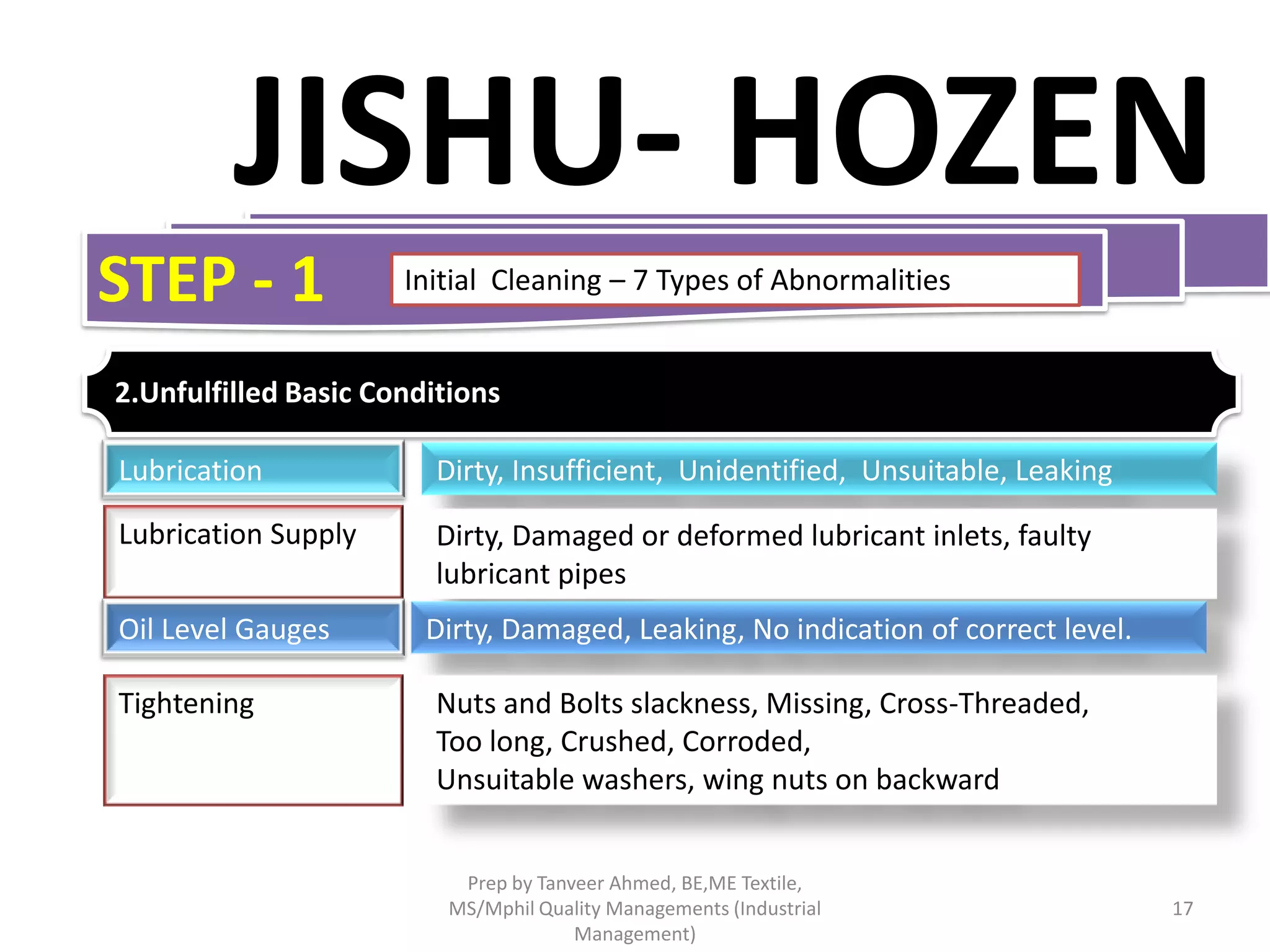

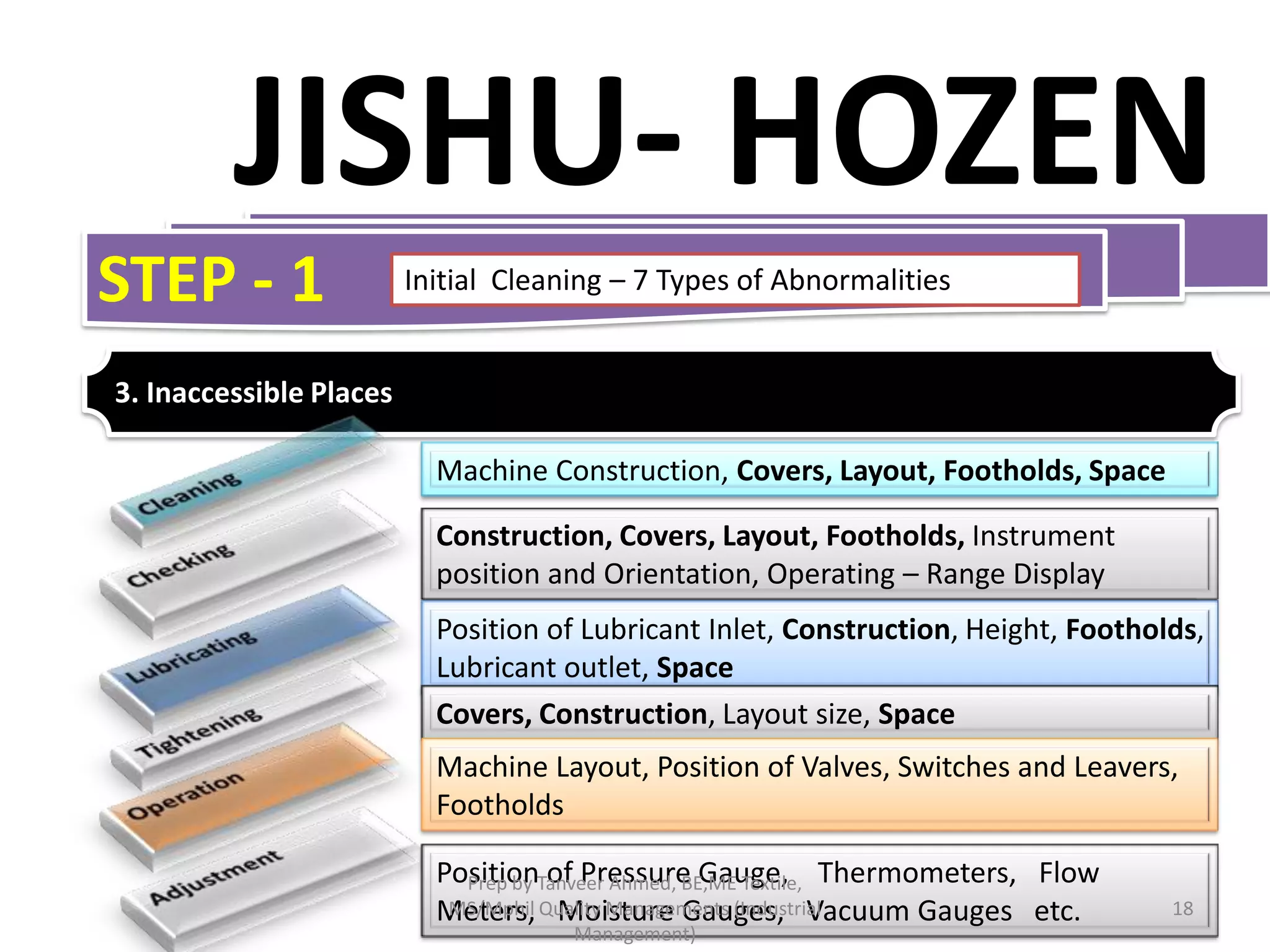

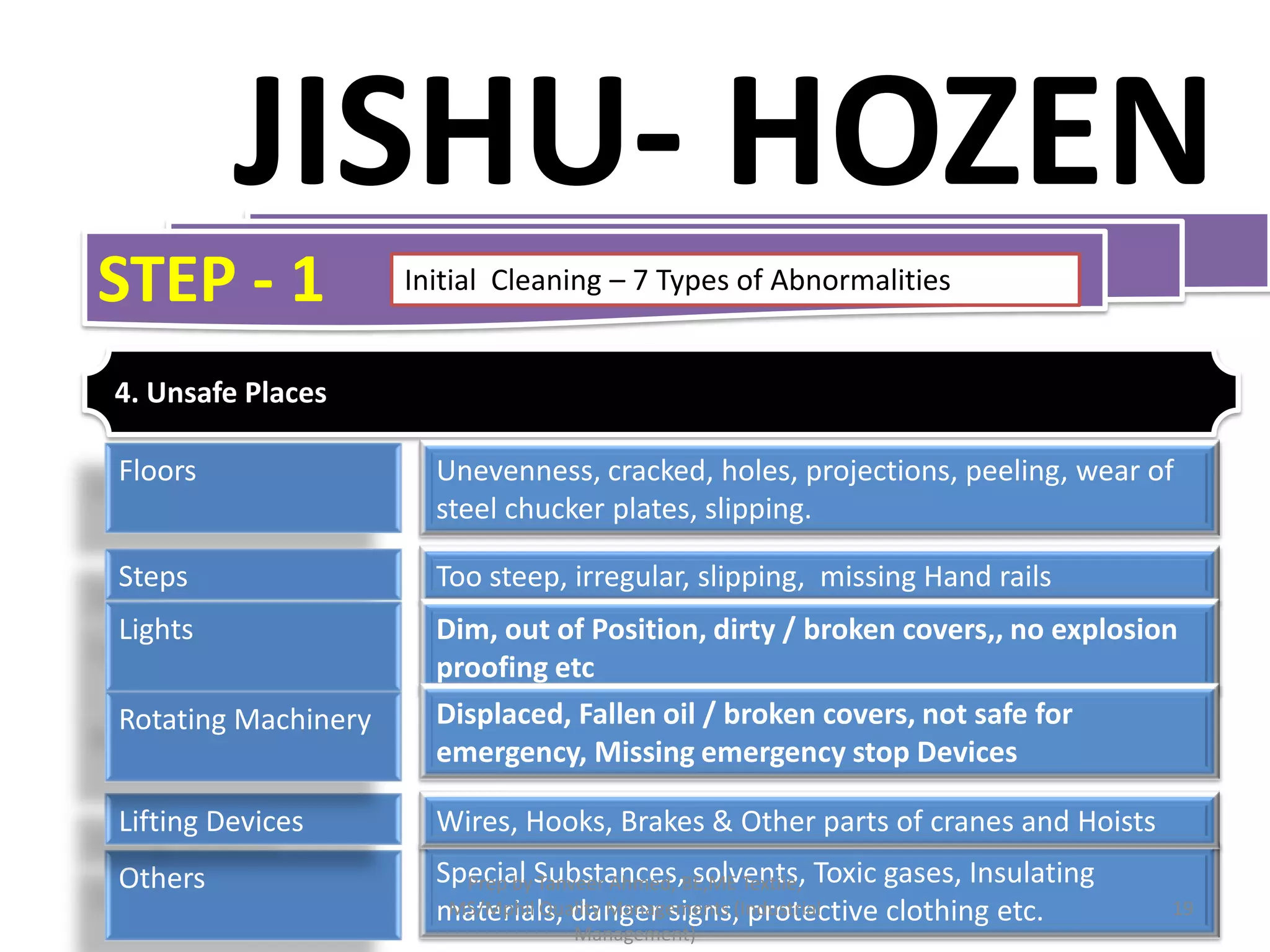

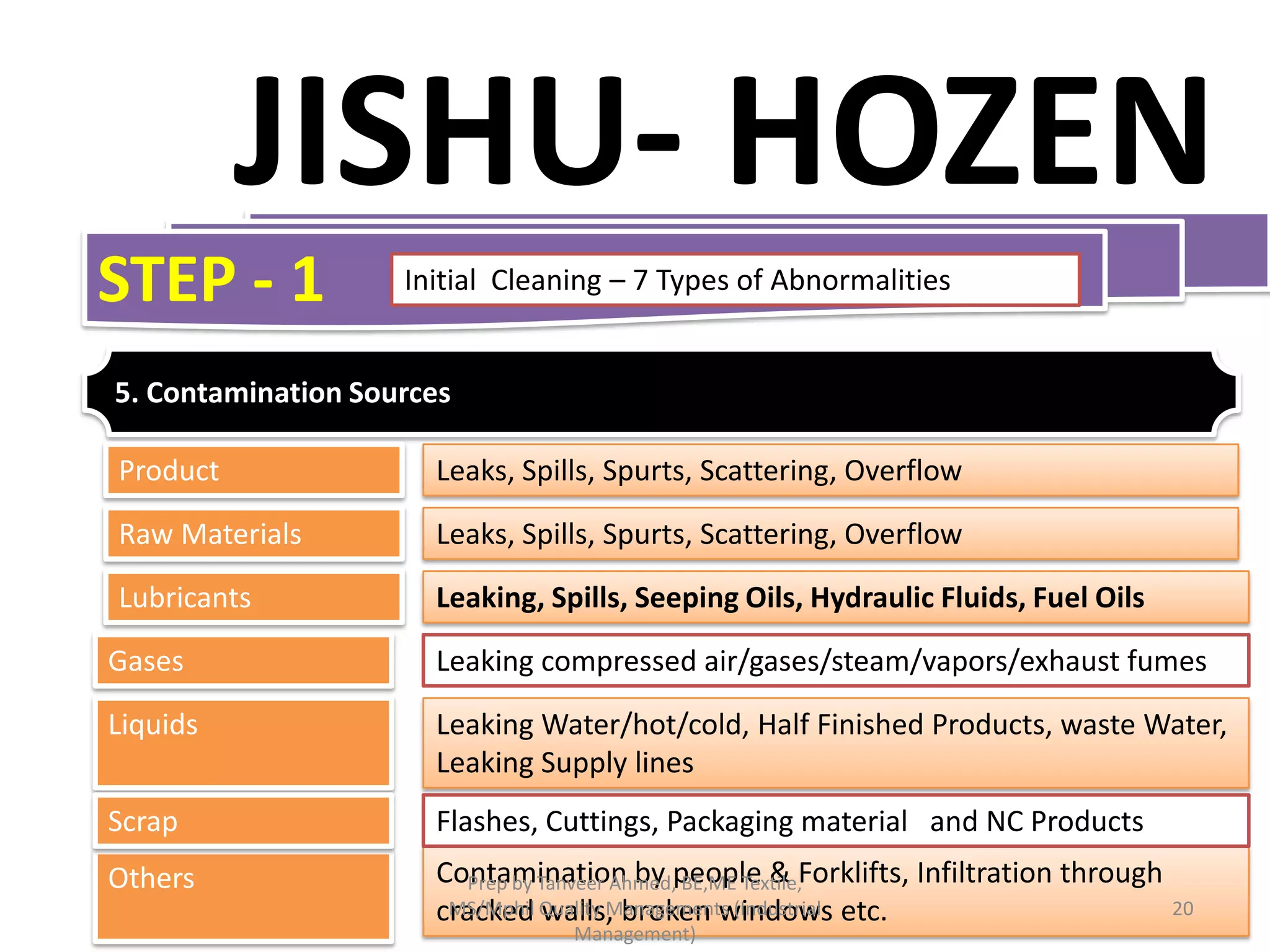

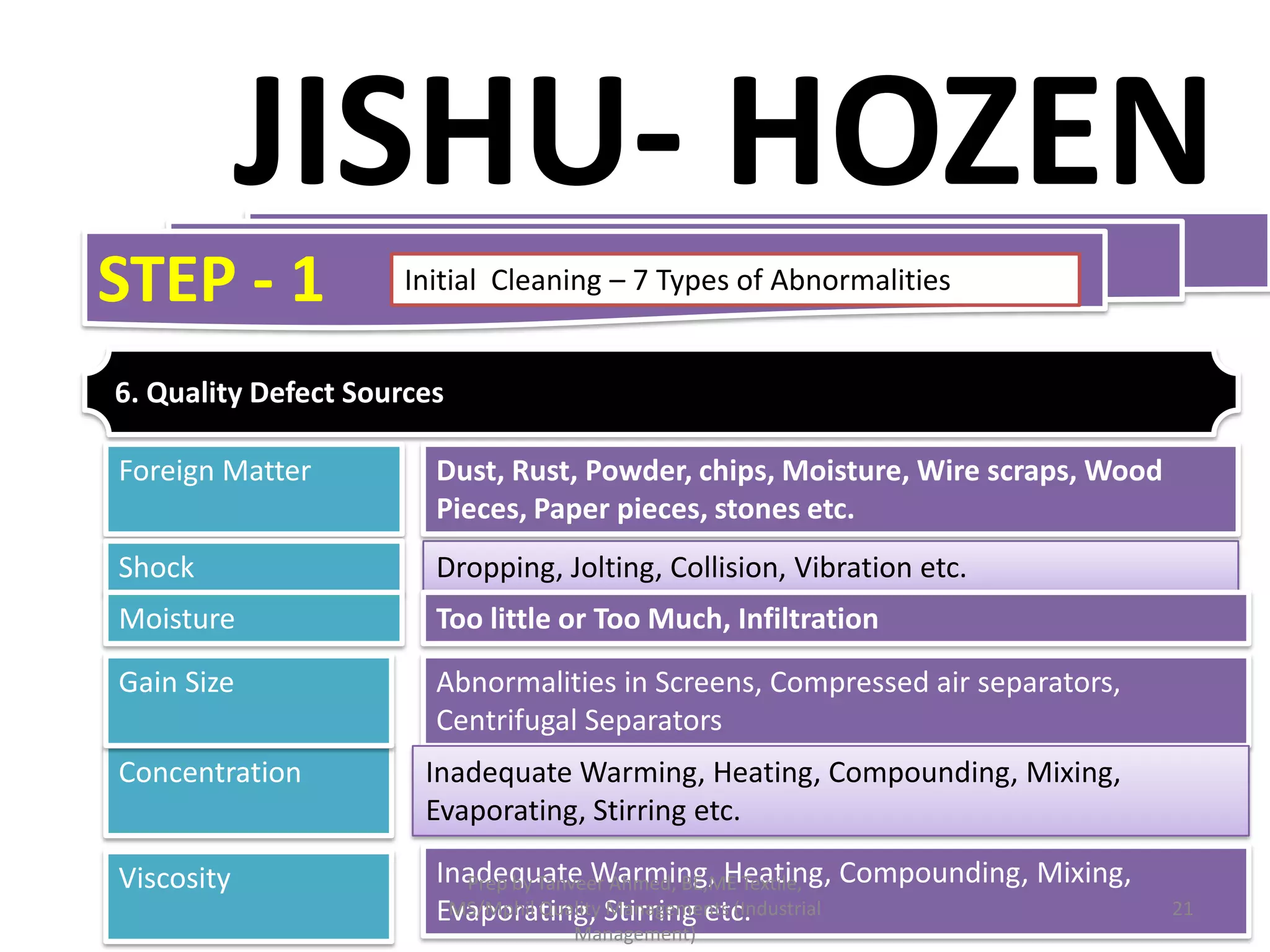

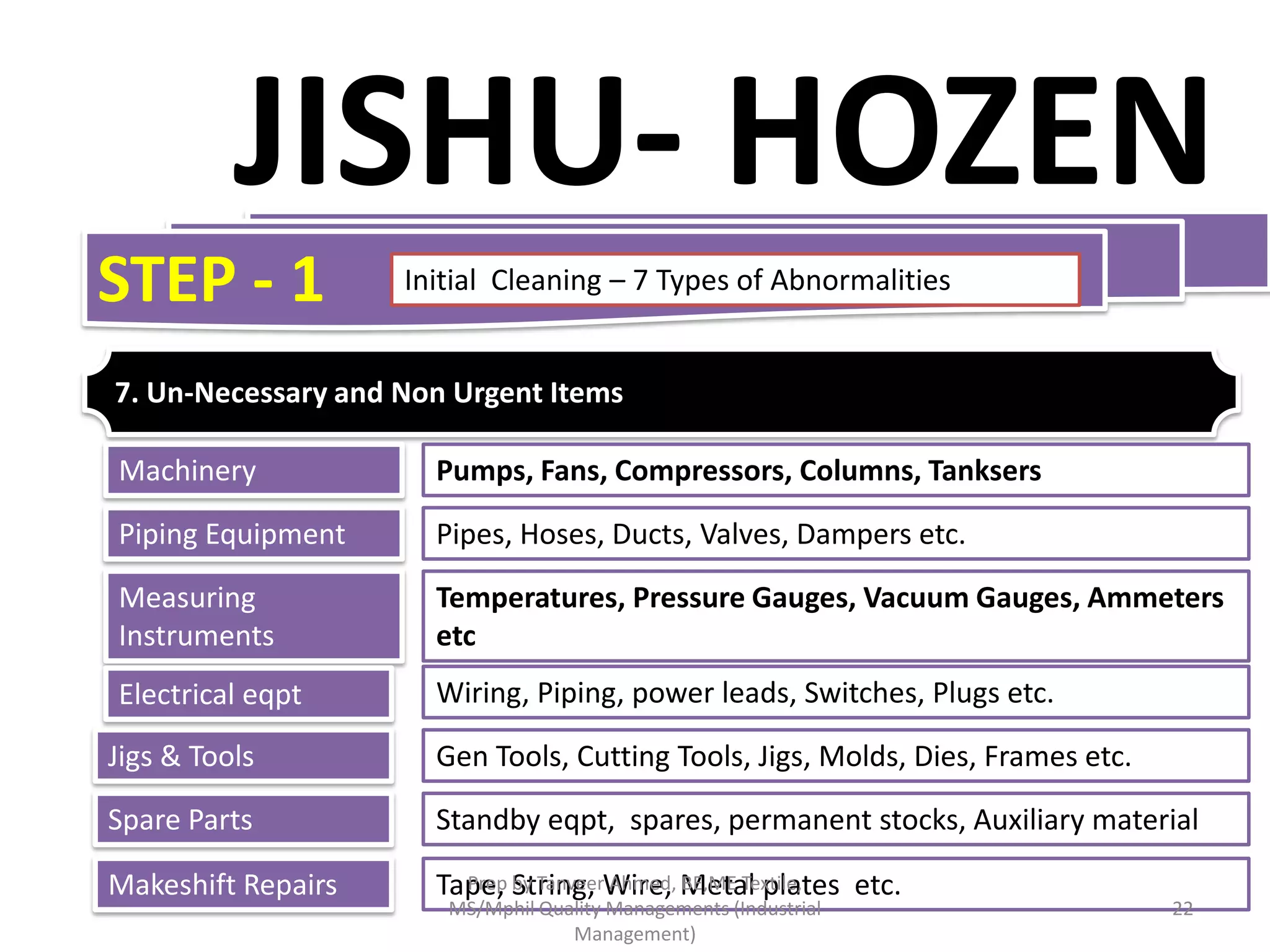

The document describes the process of Jishu-Hozen, or autonomous maintenance. It includes 7 steps: 1) initial cleaning, 2) measures against sources of contamination, 3) formulation of cleanup and lubrication standards, 4) general inspection, 5) autonomous inspection, 6) standardization, and 7) autonomous management. The goals are to prevent equipment issues, reduce maintenance costs, and increase operator involvement in maintenance through standardized processes and inspections led by cross-functional teams.