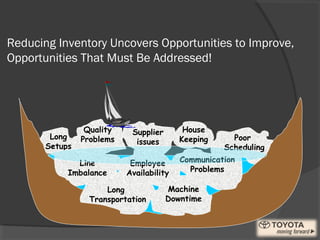

This document provides an overview of MUDA (waste) training. It defines the three types of waste - MUDA, MURA, and MURI. MUDA refers to any non-value adding activity and the document outlines the eight main types of MUDA: overproduction, inventory, transportation, motion, processing, defects, waiting, and underutilized skills. For each type of waste, common causes are described and suggestions are provided for how to eliminate that specific waste. The overall message is that identifying and removing waste improves process flow and efficiency.