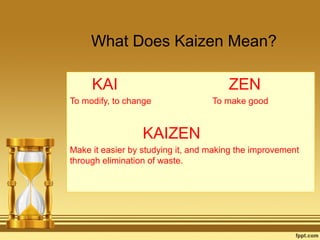

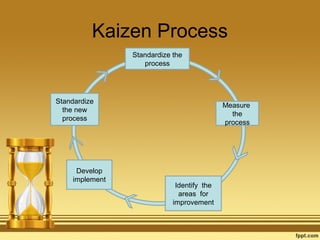

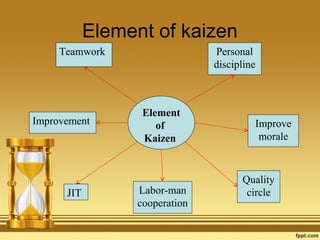

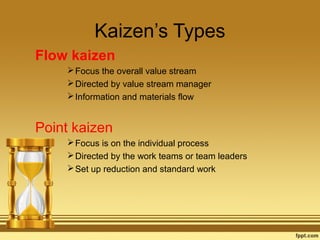

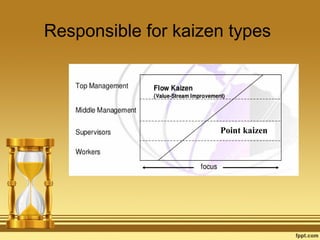

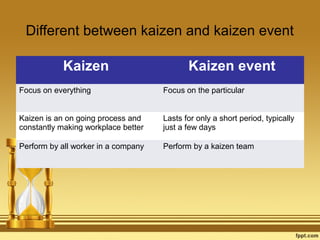

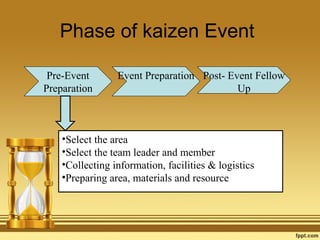

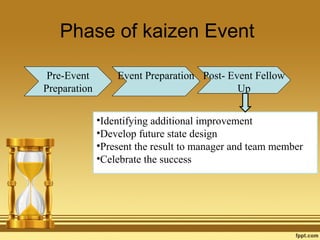

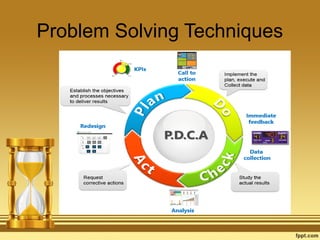

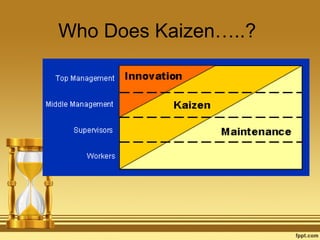

This document discusses the concept of Kaizen, which means continuous improvement. It defines Kaizen as modifying or changing processes to make them better by eliminating waste through studying and improving them. The document outlines the Kaizen process, elements, types (flow and point), and compares Kaizen to Kaizen events. It describes the phases of a Kaizen event from preparation to follow up. Finally, it discusses problem solving techniques used in Kaizen and why organizations implement Kaizen to eliminate waste, improve quality, cost and delivery, and minimize production costs by teaching workers continuous improvement.