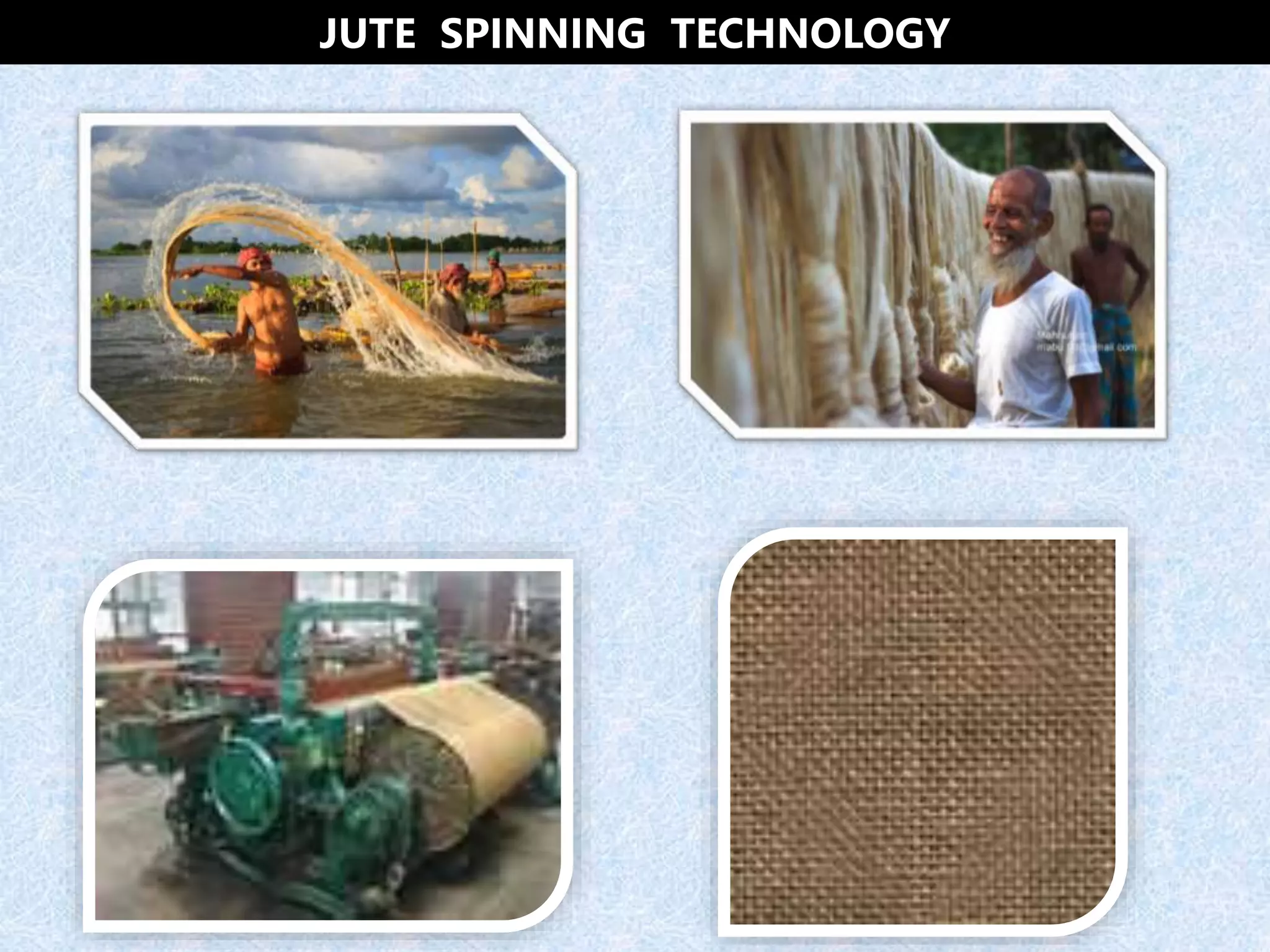

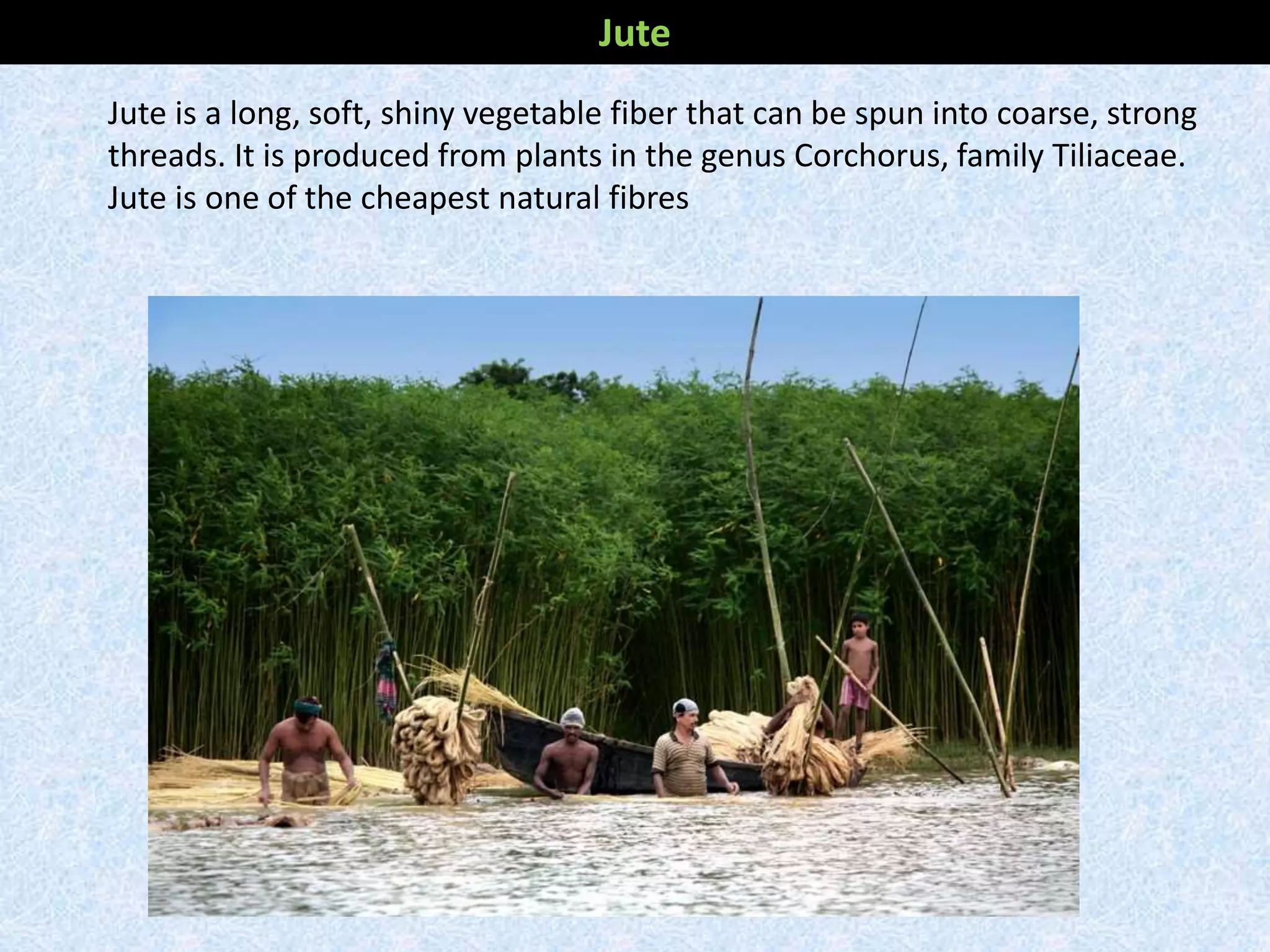

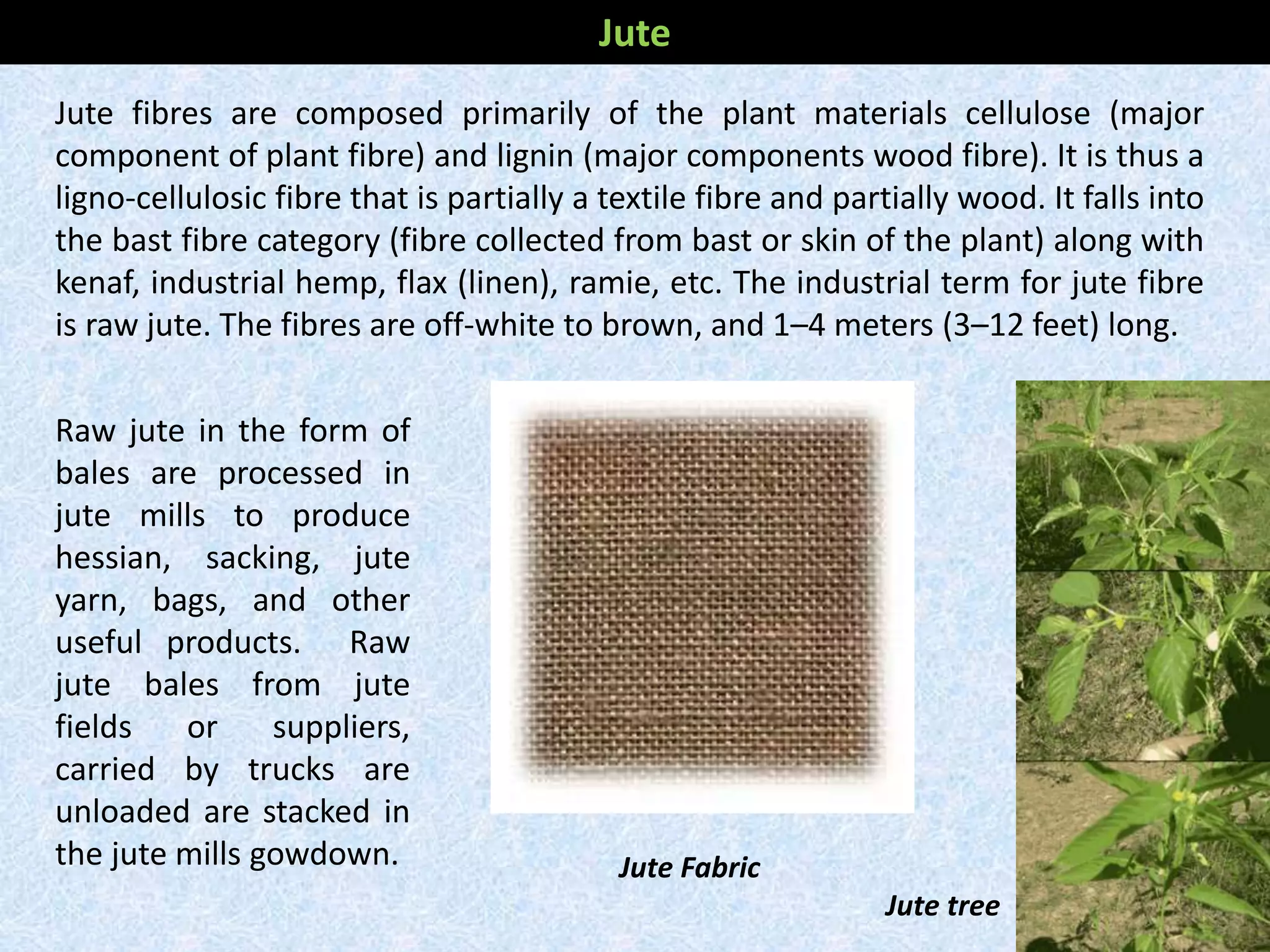

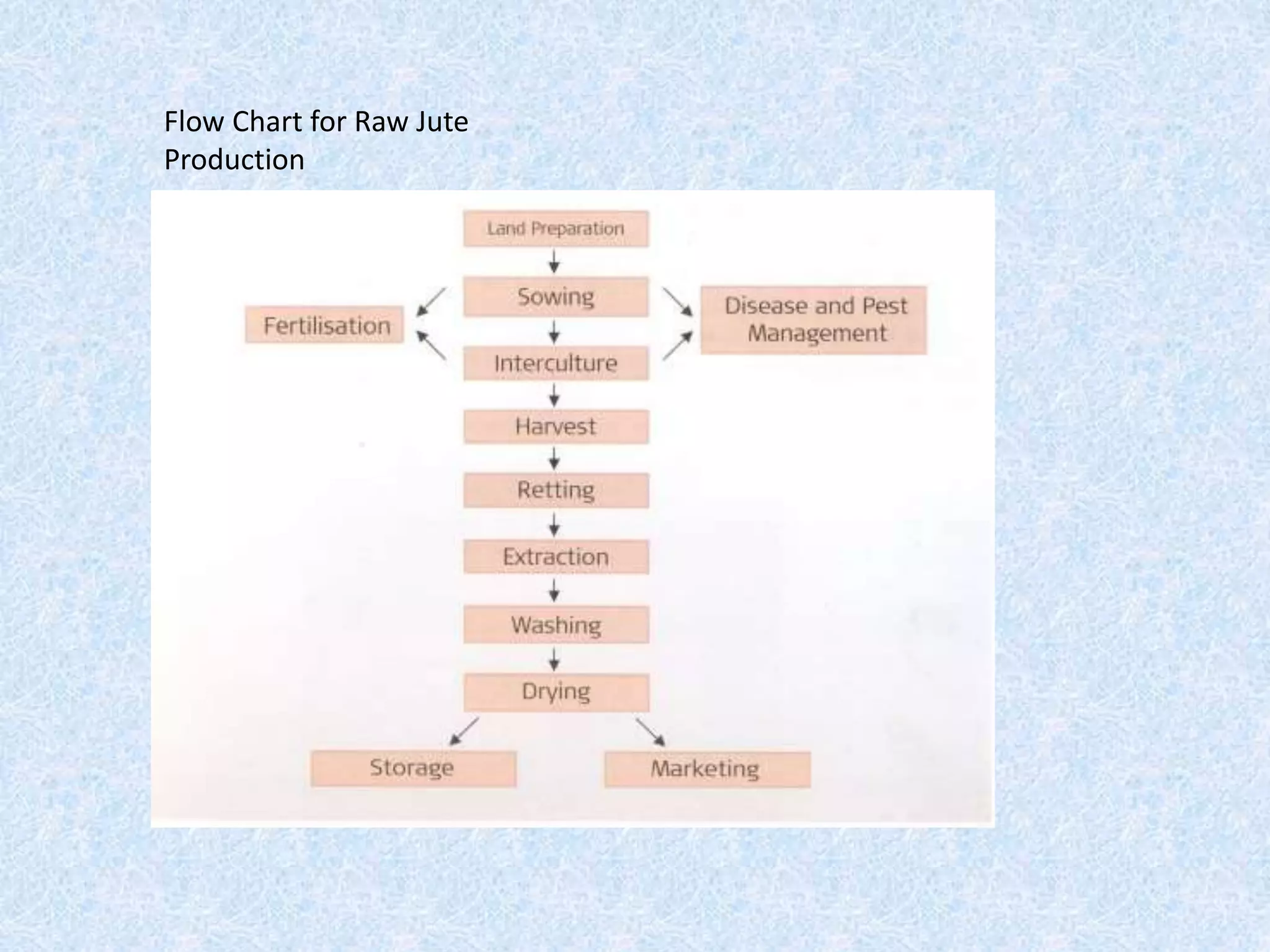

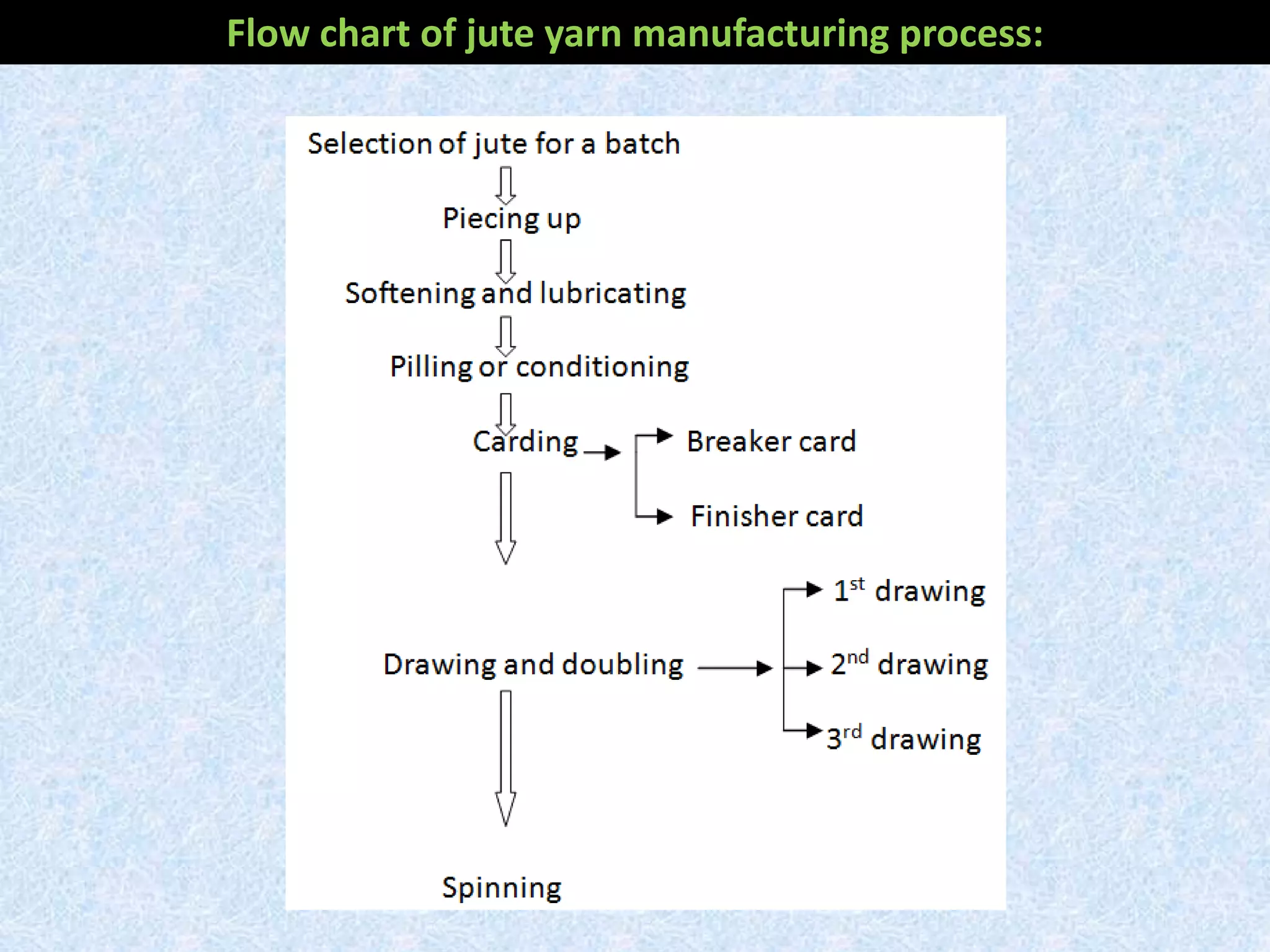

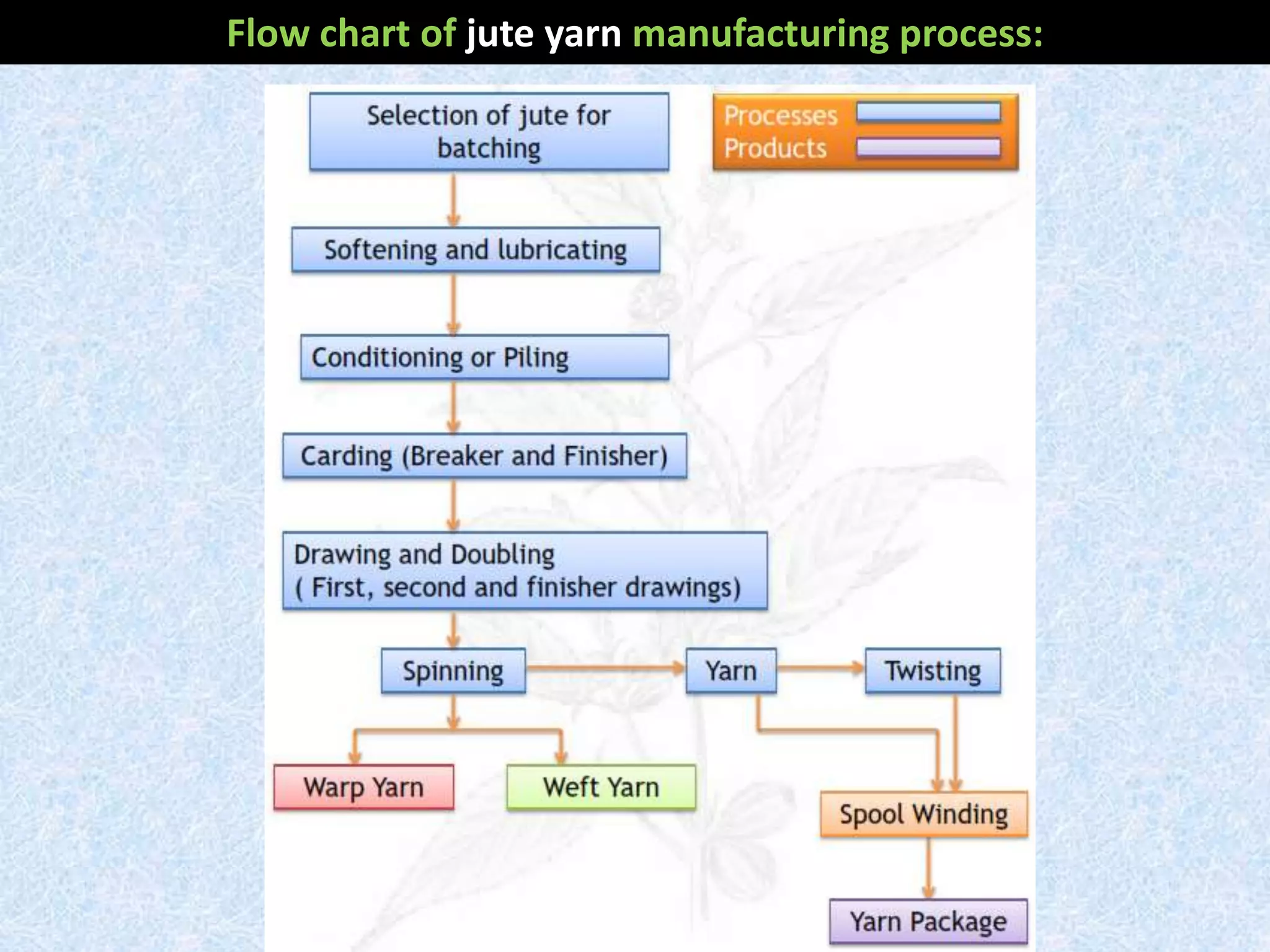

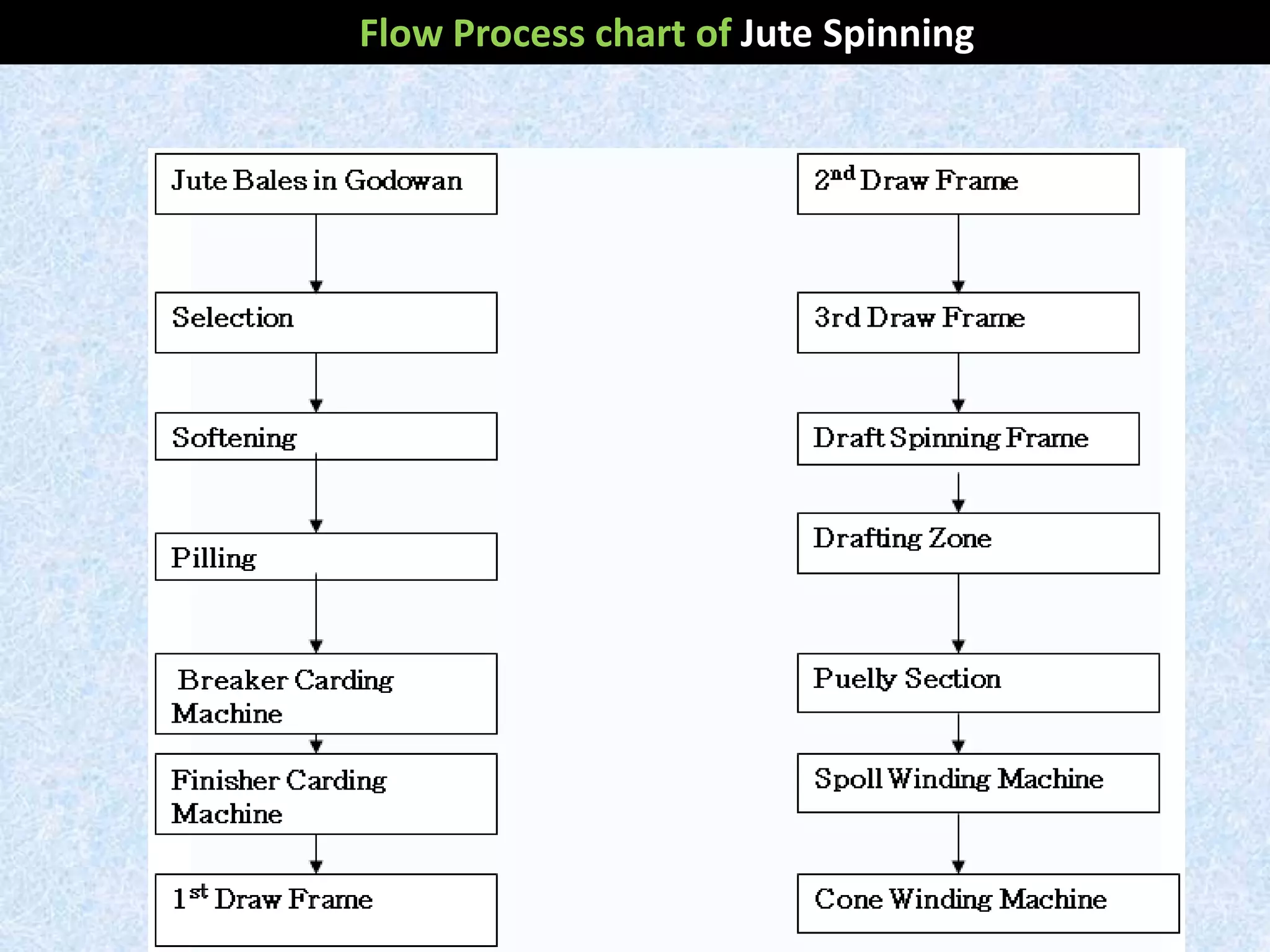

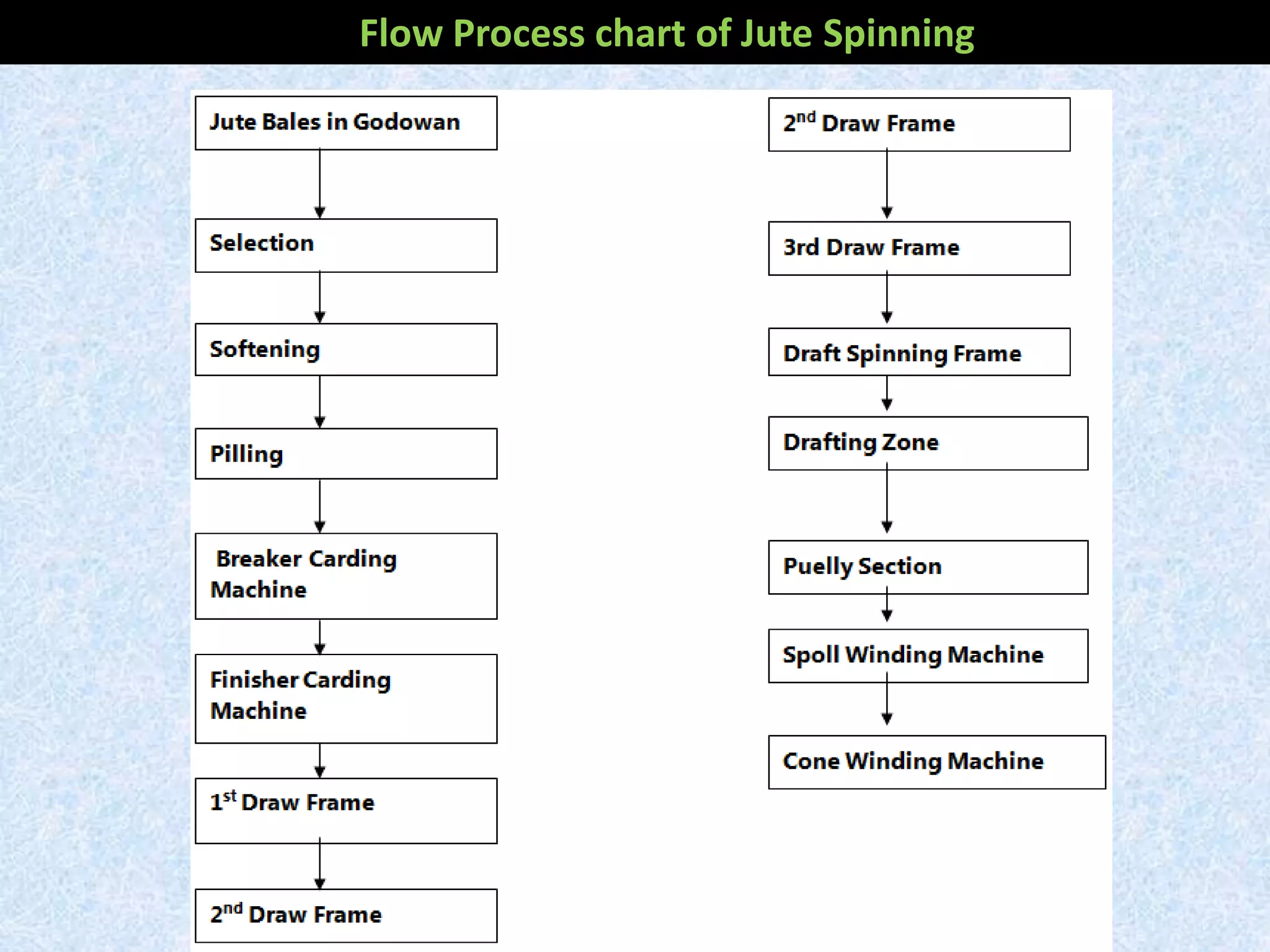

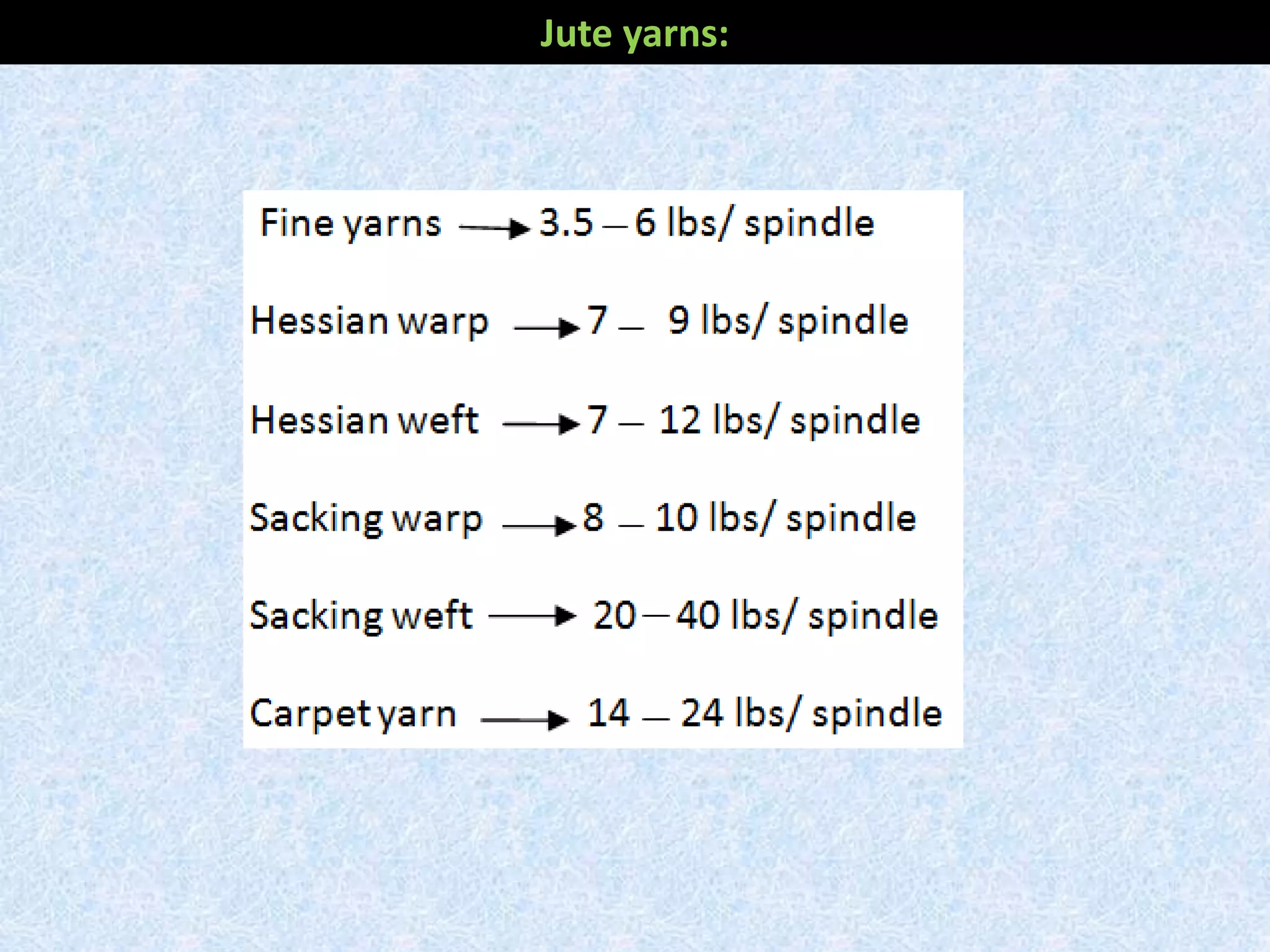

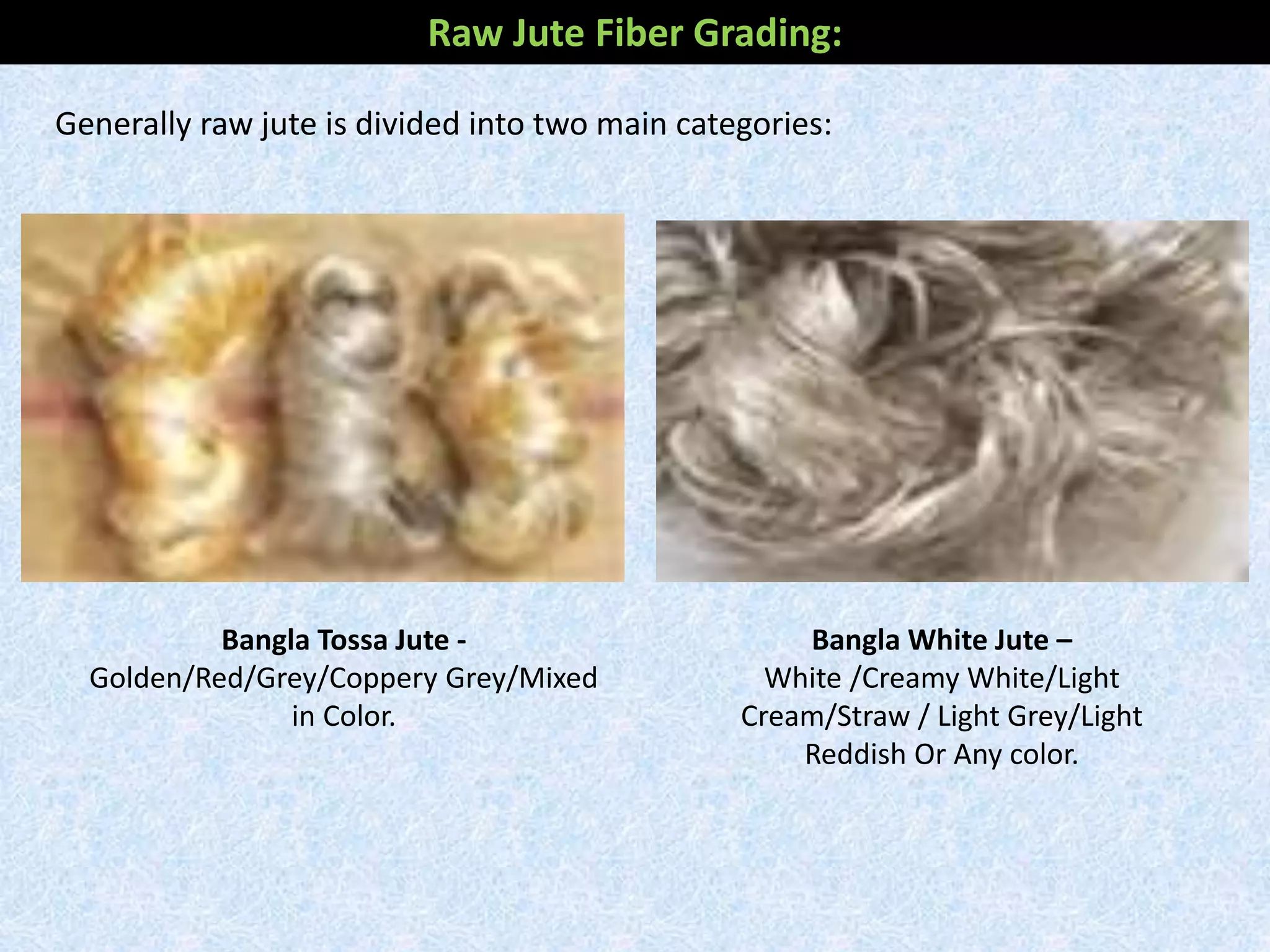

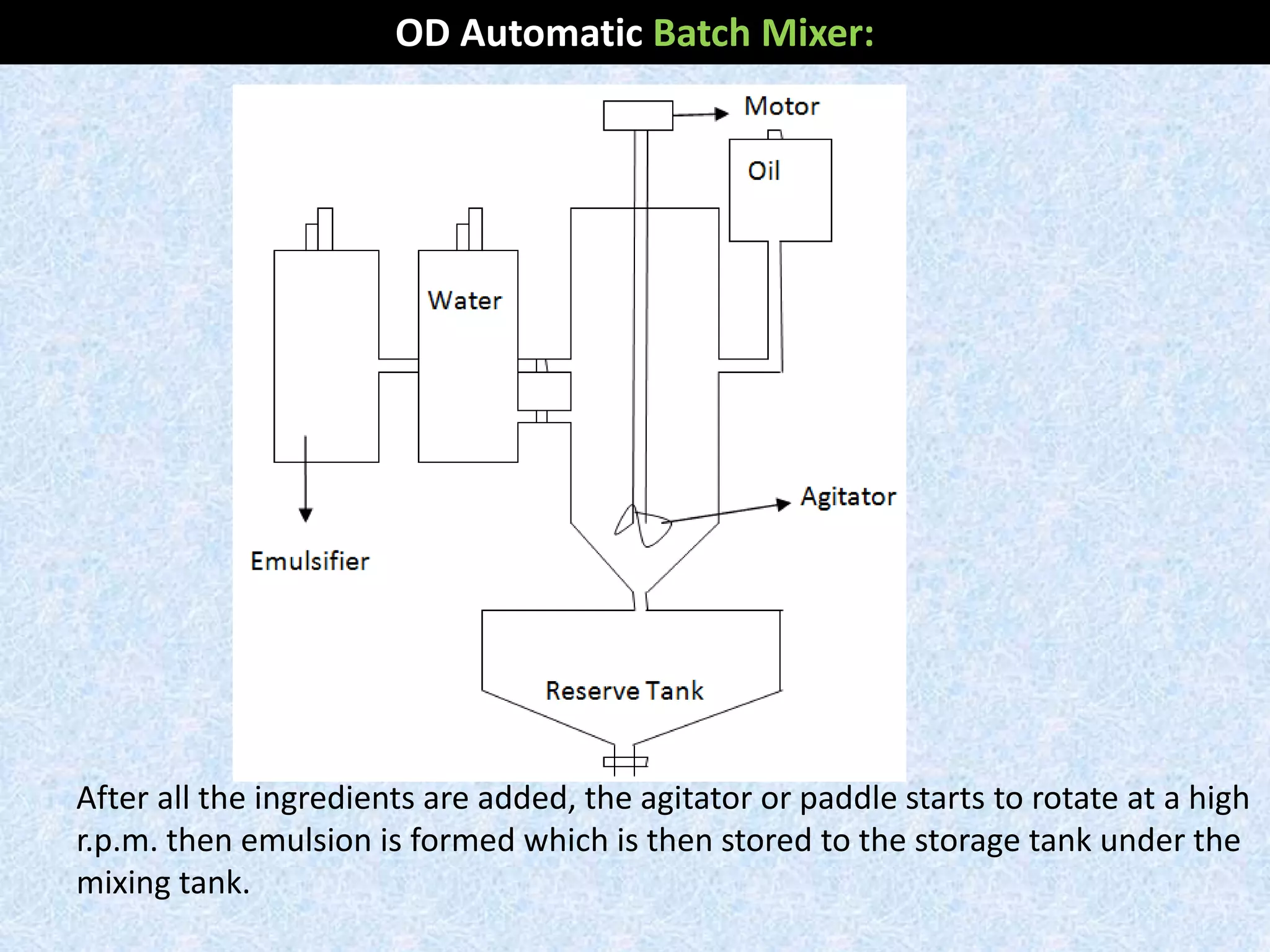

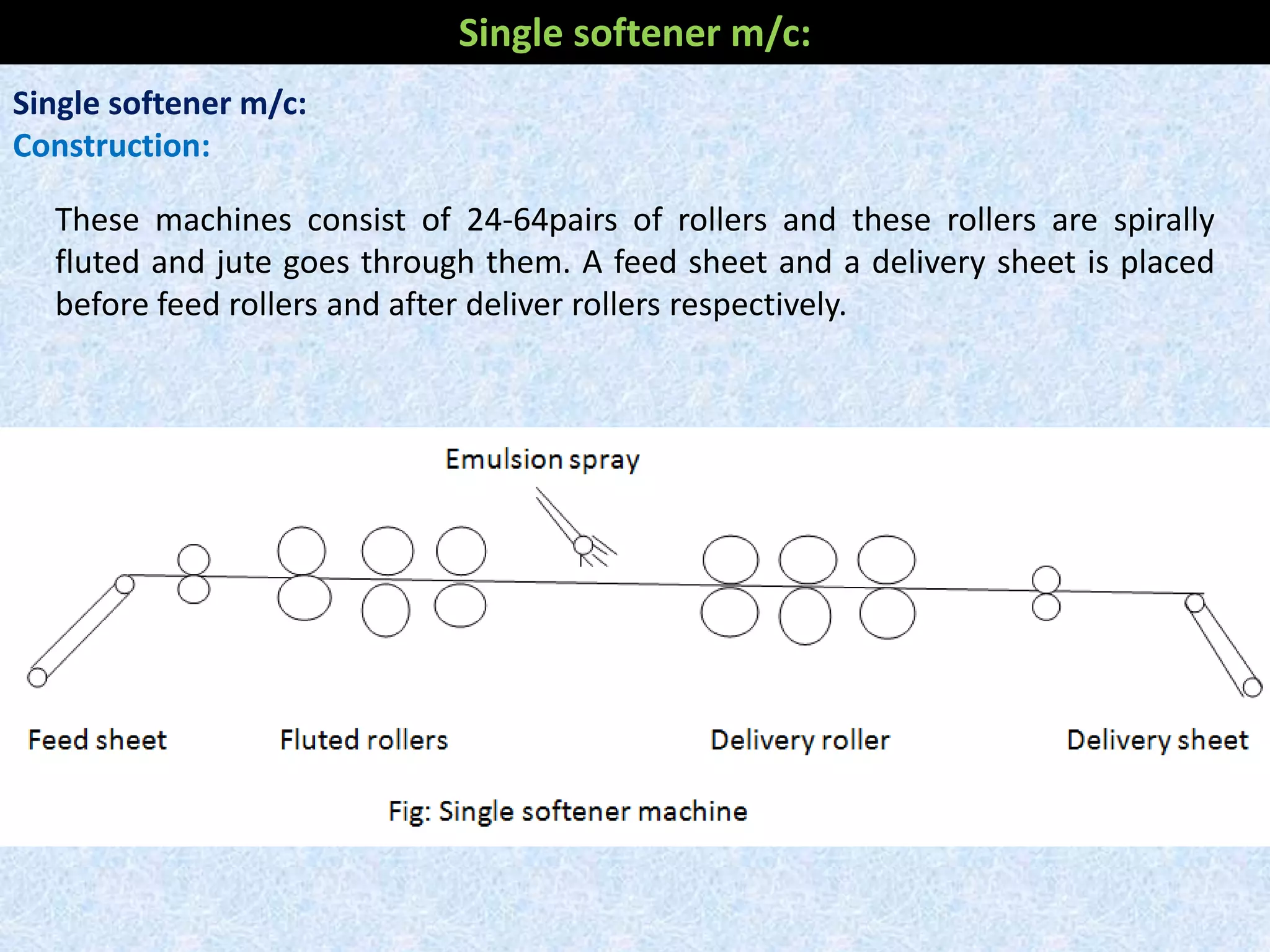

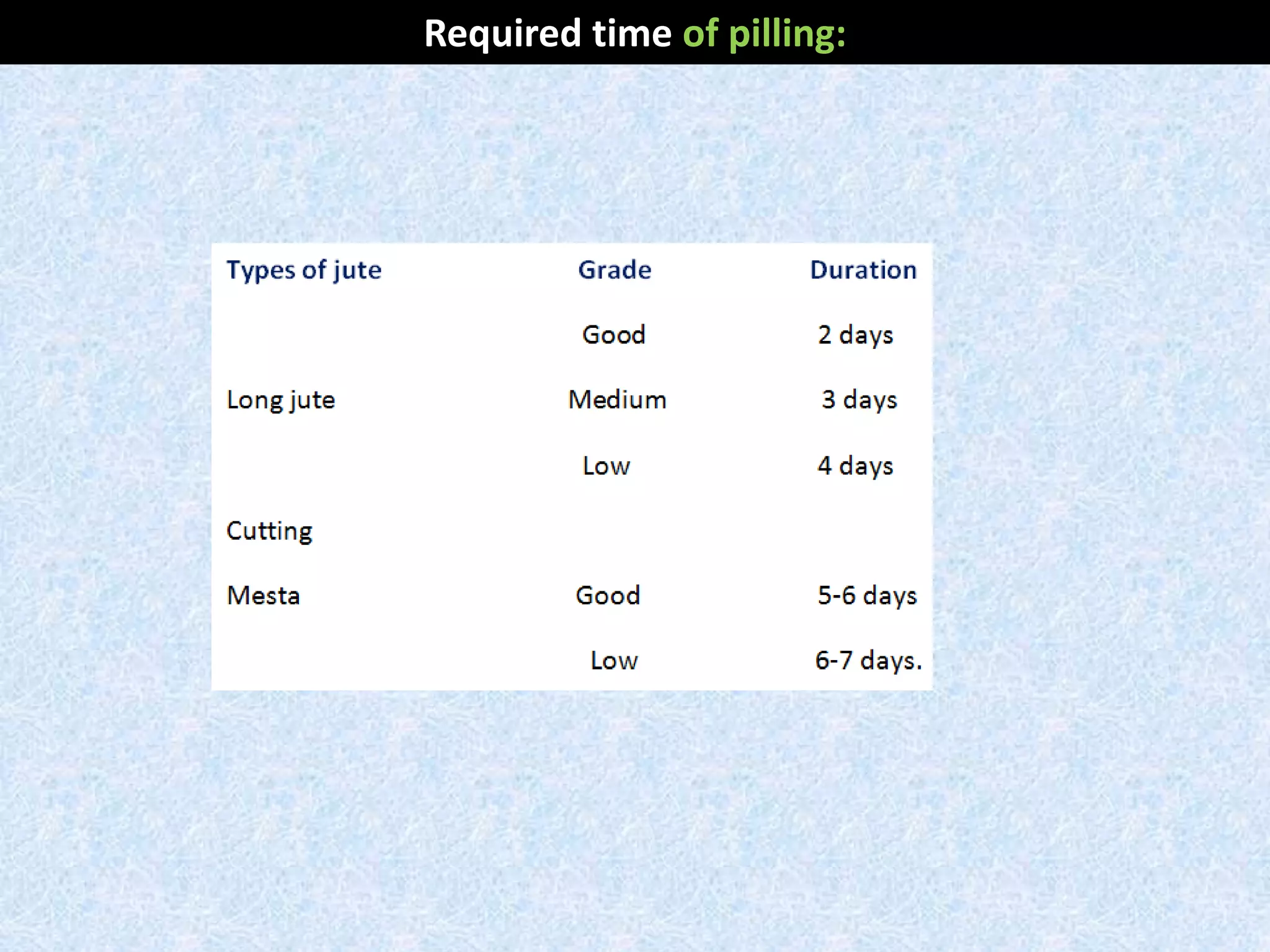

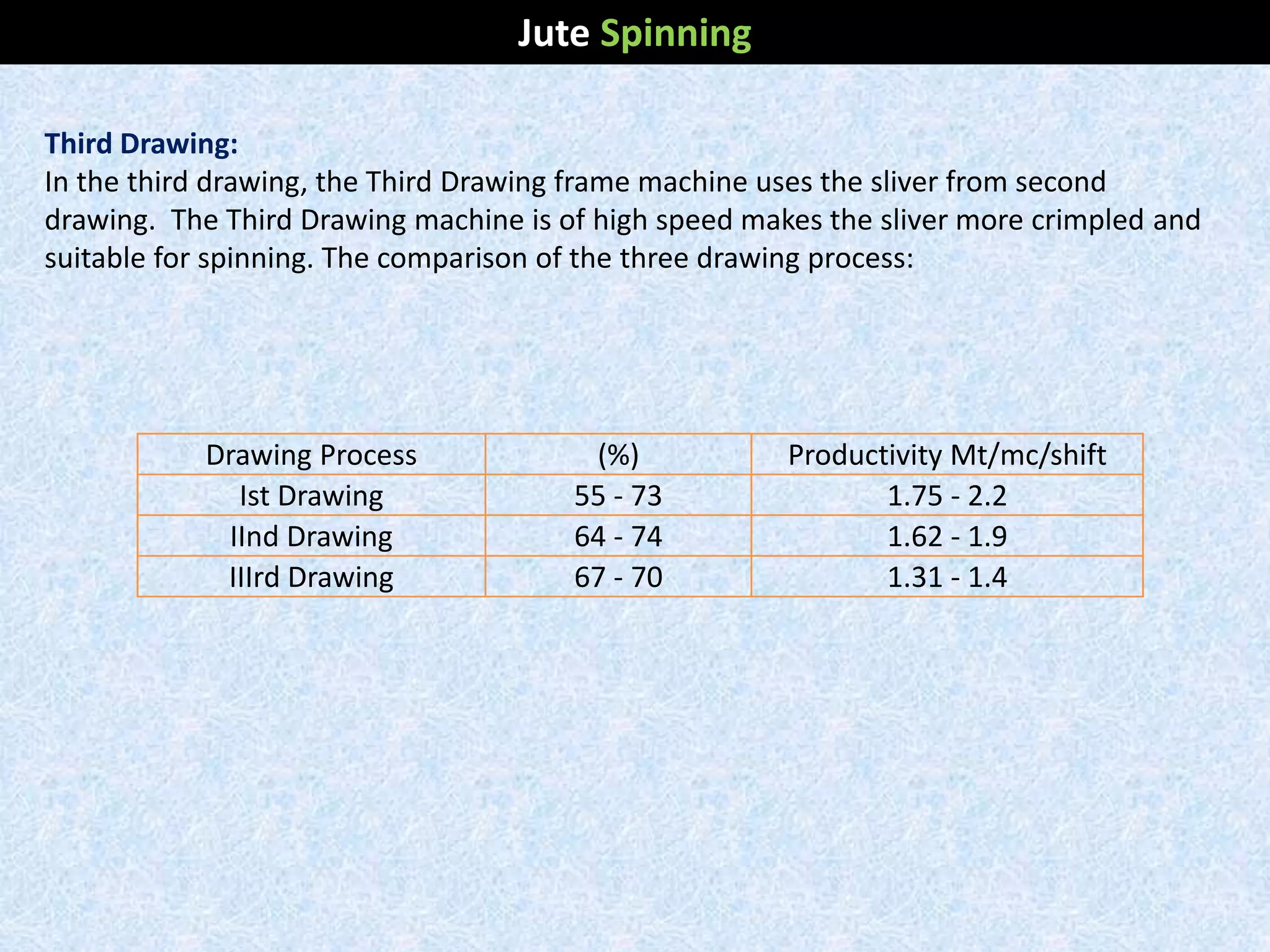

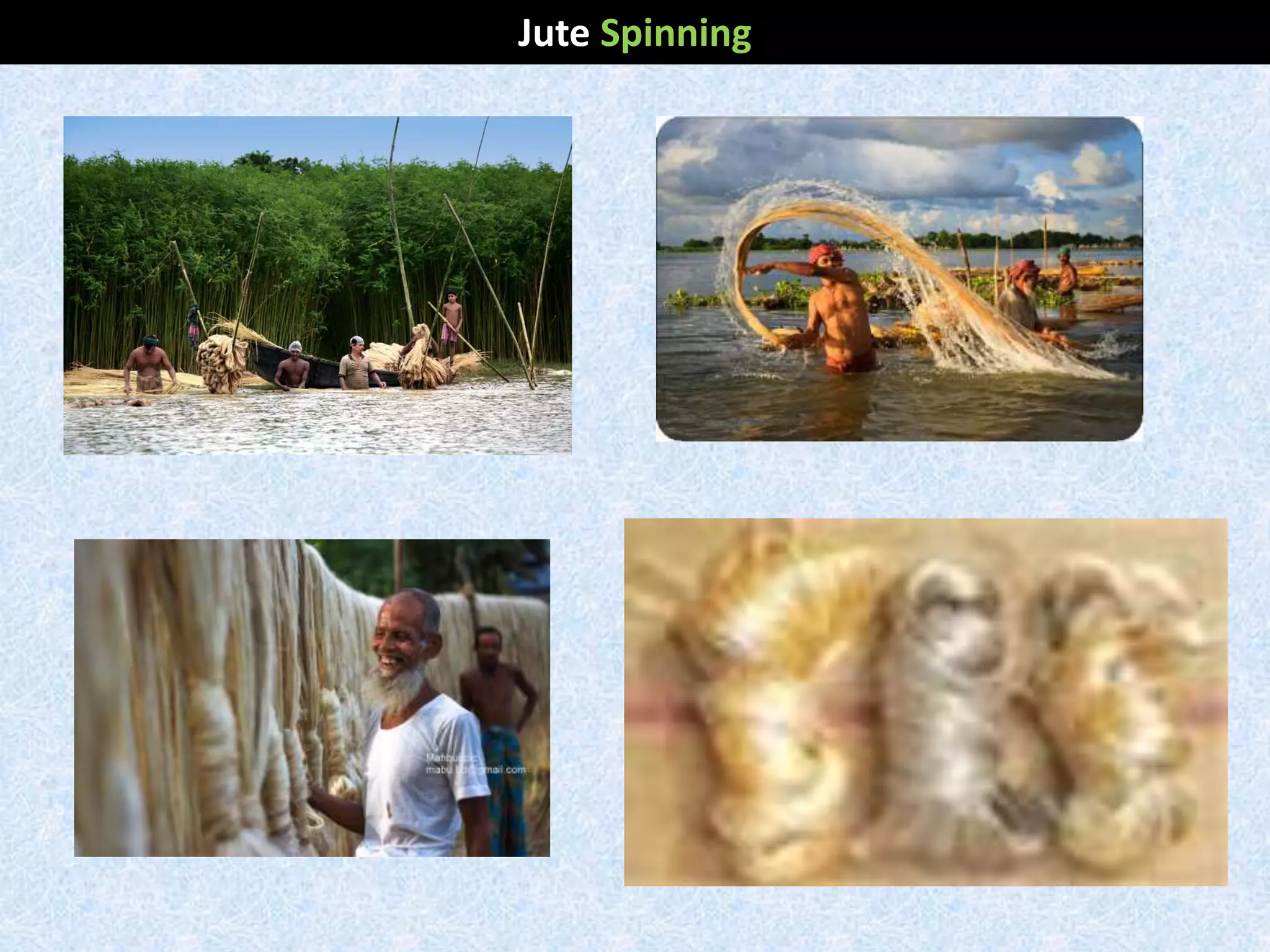

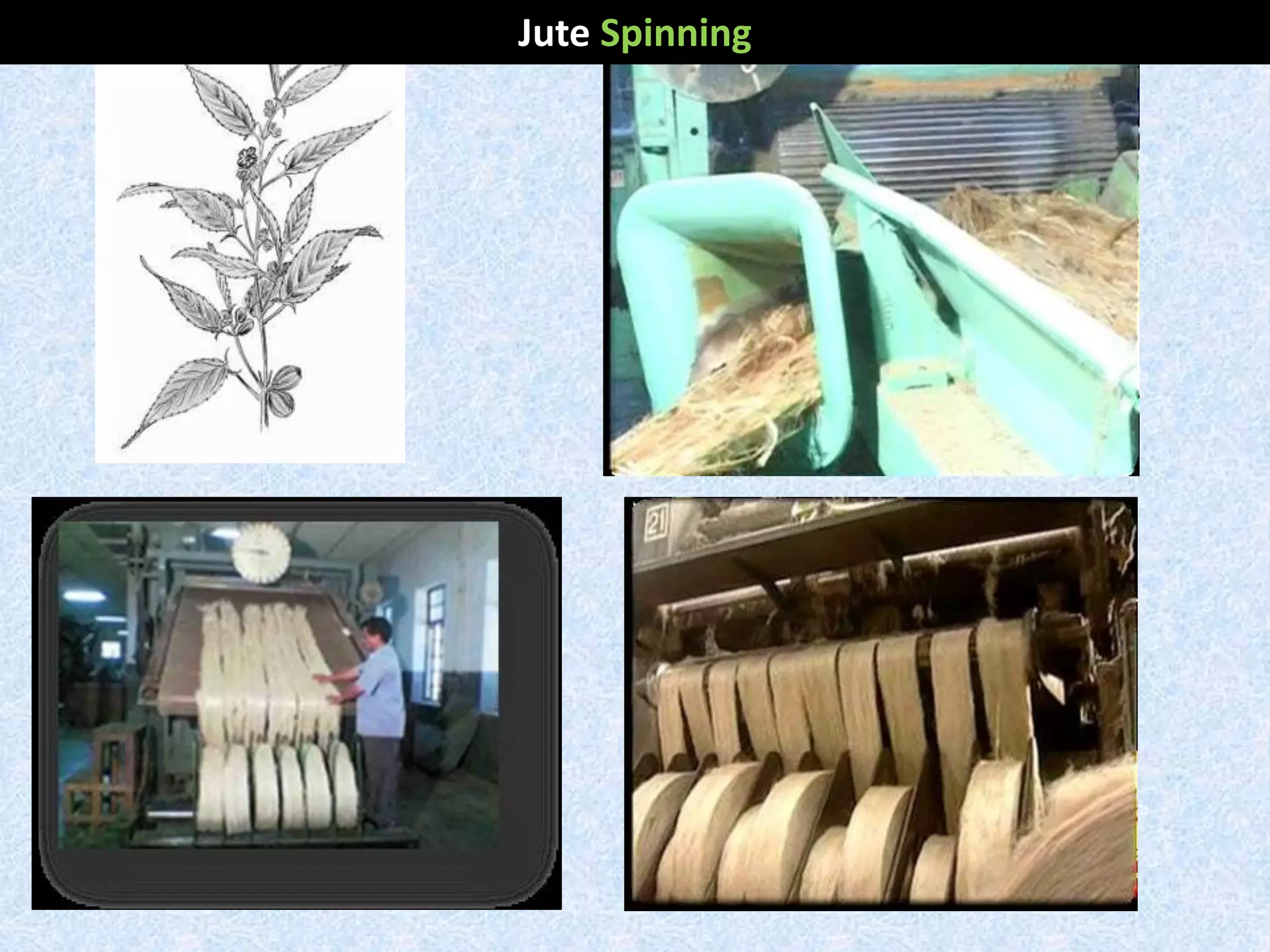

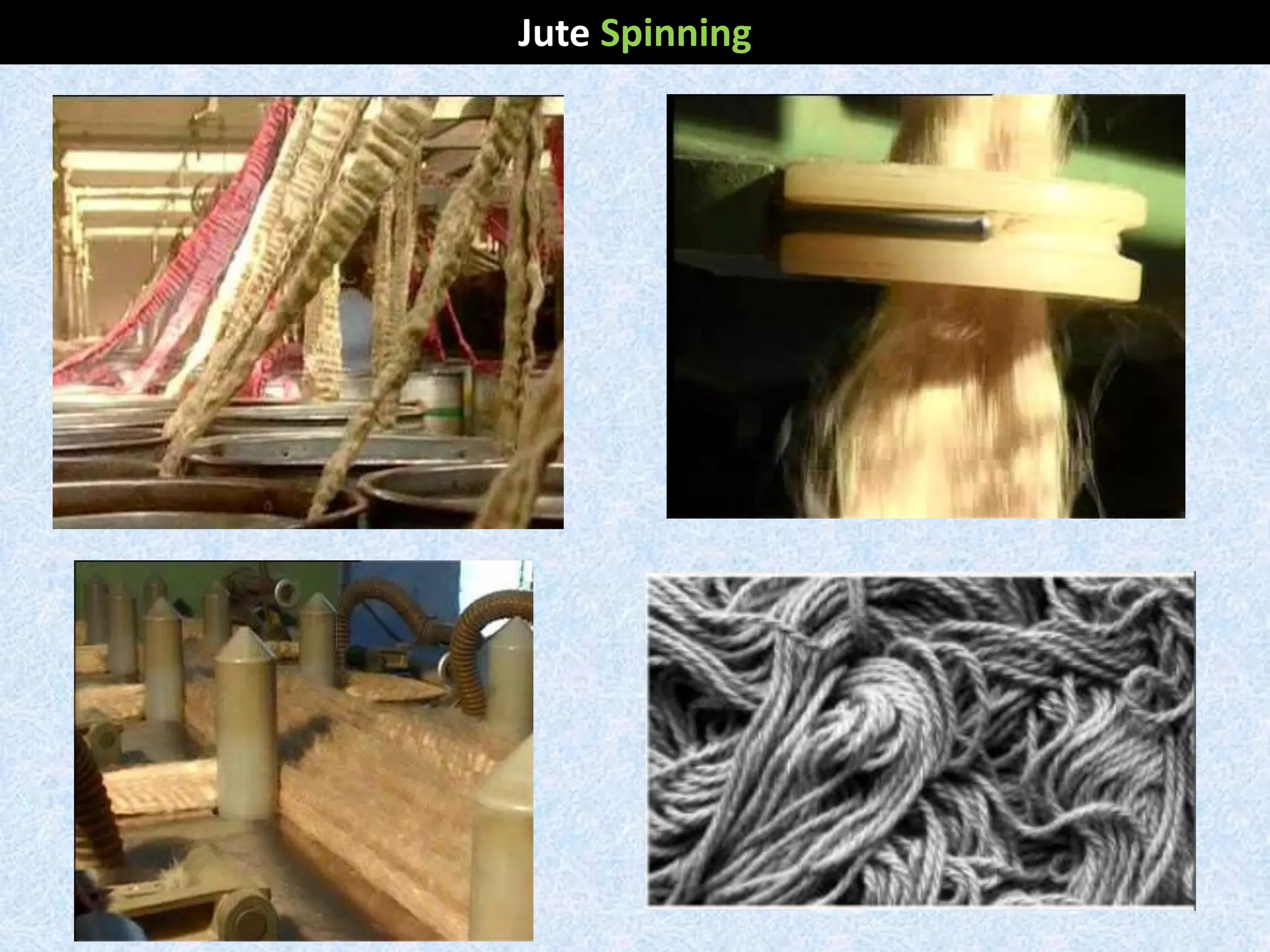

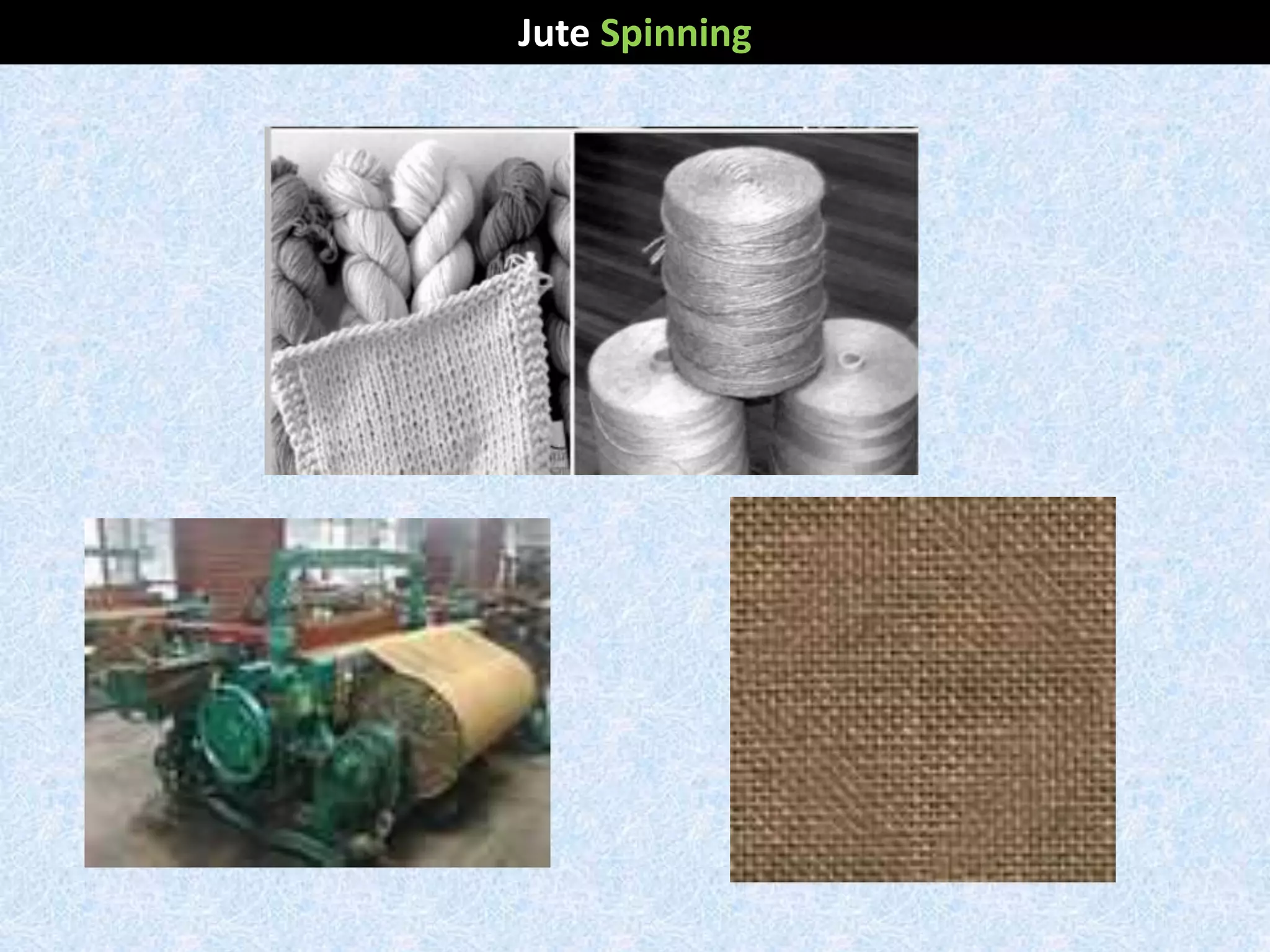

This document provides information about jute spinning technology. It discusses that jute is a soft vegetable fiber that can be spun into coarse threads. Raw jute bales are processed in jute mills to produce products like hessian, sacking, and jute yarn. It also describes the characteristics of jute fiber and provides details about various stages of jute processing like batching, softening, carding, drawing, and winding.