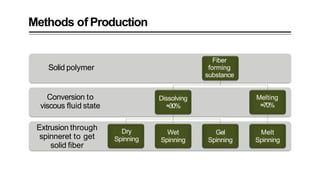

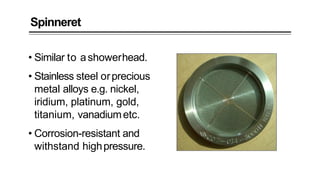

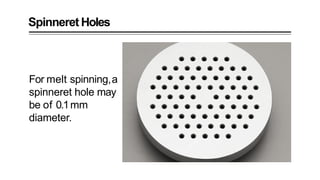

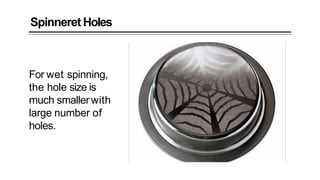

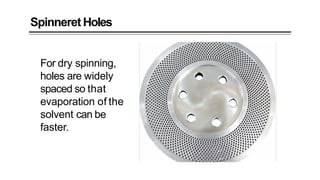

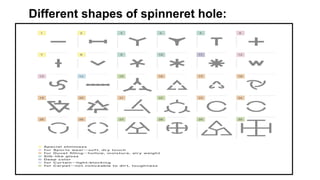

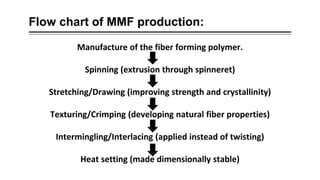

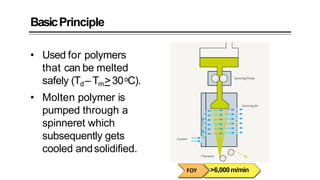

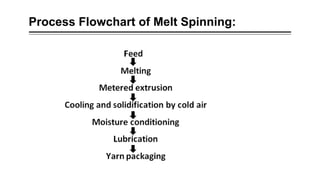

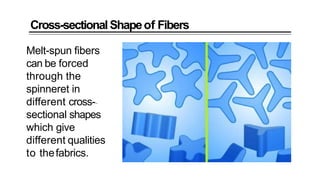

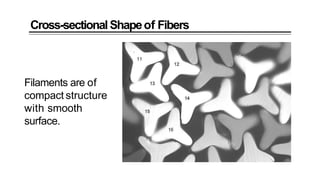

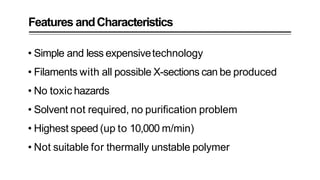

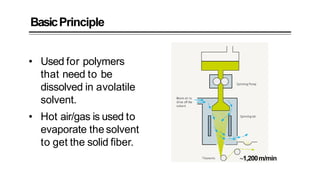

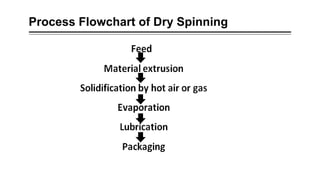

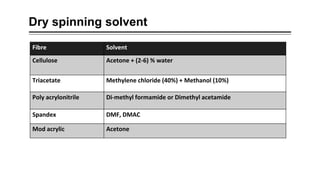

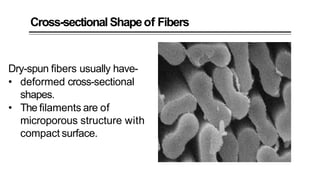

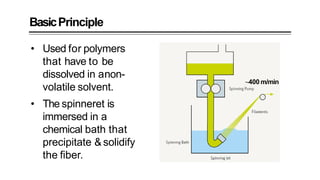

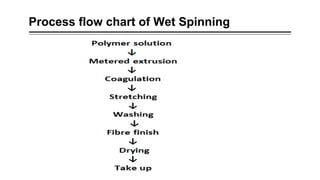

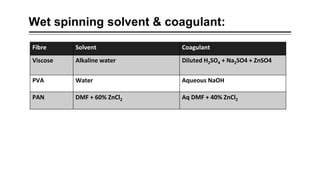

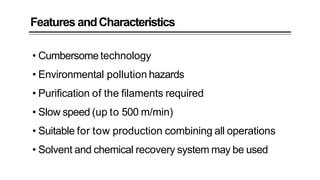

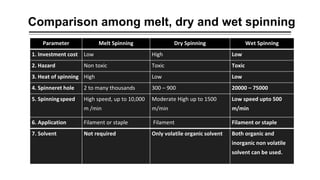

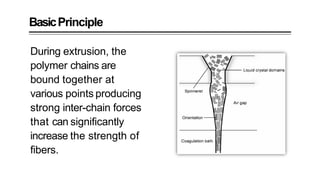

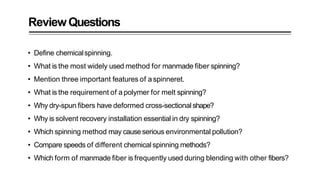

Chemical spinning is the process of converting a fiber-forming substance into a viscous fluid that is extruded through spinneret holes and then solidified. The most widely used chemical spinning method is melt spinning, which is used for polymers that can be melted safely. A spinneret must have corrosion-resistant holes of controlled dimensions to produce uniform fibers and withstand high pressures. Melt spinning is the fastest chemical spinning method. Dry spinning fibers often have deformed cross-sectional shapes due to uneven solidification from the exterior to interior layers. Solvent recovery is essential for dry spinning to minimize environmental and economic costs. Wet spinning poses the highest pollution risks of the three methods discussed.