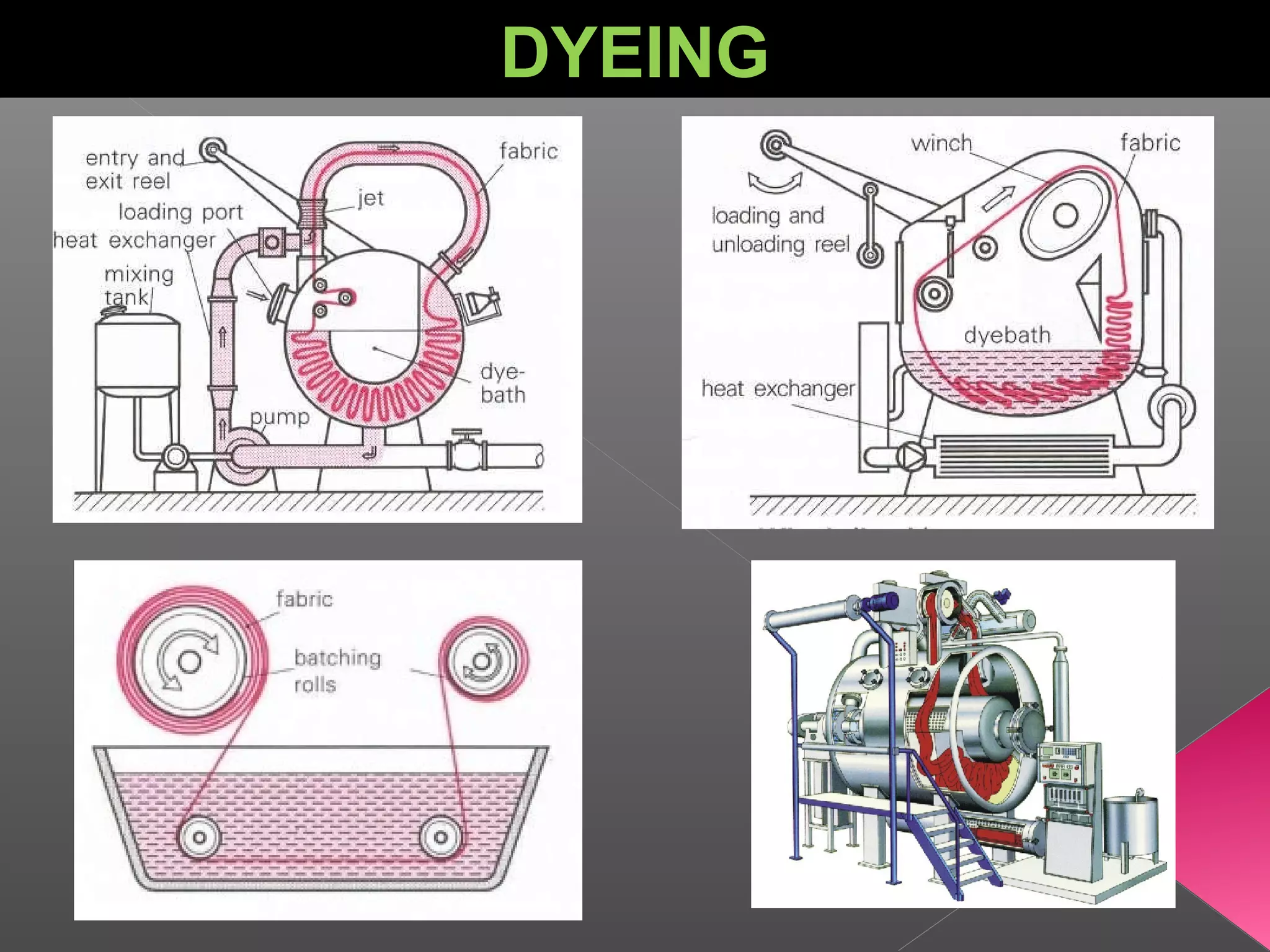

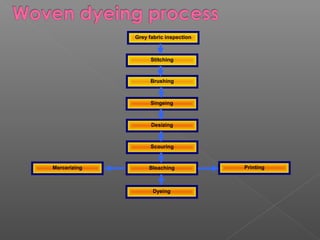

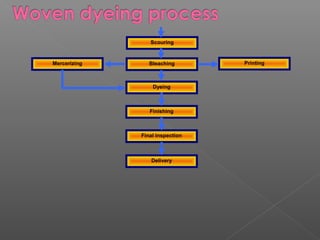

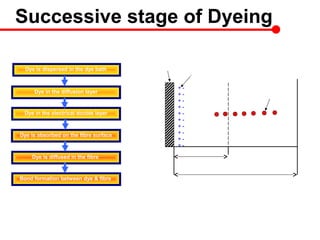

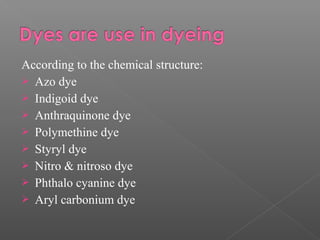

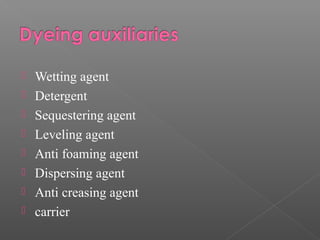

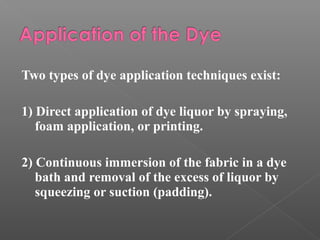

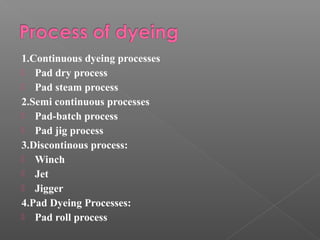

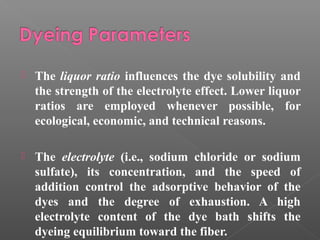

This document discusses the process of dyeing textiles. It explains that there are three main types of dyeing: fiber, yarn and fabric dyeing. The dyeing process involves successive stages including dispersing dye in a dye bath, diffusion of dye onto and into the fiber substrate, and bonding between dye and fiber molecules. Dyes are also classified by their application method and chemical structure. Proper control of dye bath parameters like liquor ratio, electrolyte concentration, pH and temperature are important to ensure efficient dye absorption and an even color. Modern industrial dyeing is automated but still aims to produce textiles with homogeneous color in an economic manner with good colorfastness.