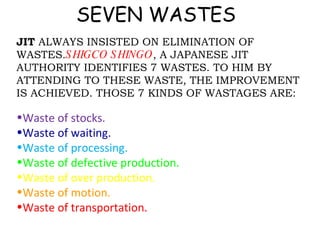

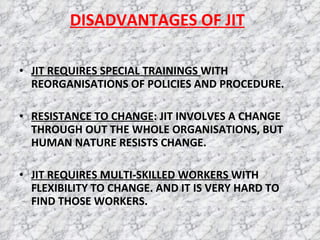

The document discusses Just-in-Time (JIT) manufacturing. It explains that JIT aims to eliminate waste from production by providing the right parts at the right time and place. The document identifies seven types of waste and lists key elements of JIT, such as having a flexible workforce and defect-free materials delivered as needed. Benefits of JIT include reduced costs, improved quality, and increased productivity and flexibility. However, JIT also requires special training and multi-skilled workers, which can be challenging to implement. In conclusion, JIT philosophy aims to cut unnecessary inventory and non-value-added activities to produce goods as specified through continuous improvement.