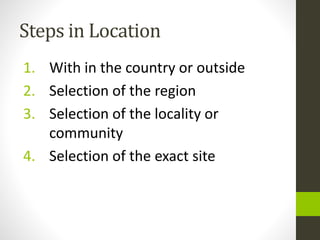

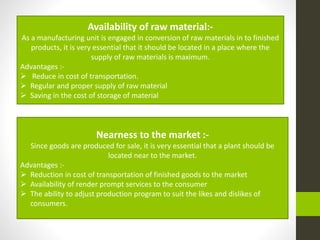

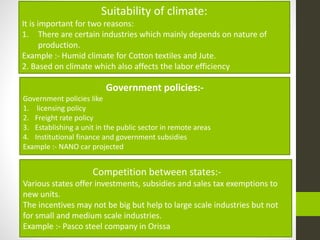

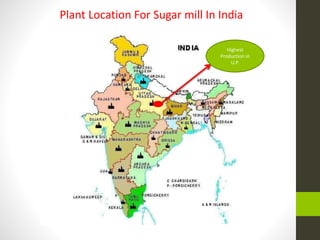

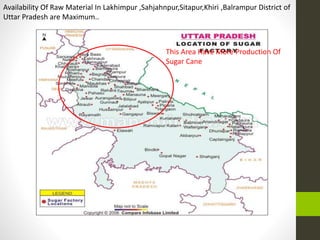

The document discusses the essential factors in selecting a plant location for maximum operational efficiency, emphasizing economic considerations and potential challenges in relocating an established facility. Key factors include proximity to raw materials, markets, transportation, power availability, labor supply, civic amenities, and government policies. The selection process involves determining the country, region, locality, and exact site for the plant, with specific examples provided for industries such as sugar manufacturing.