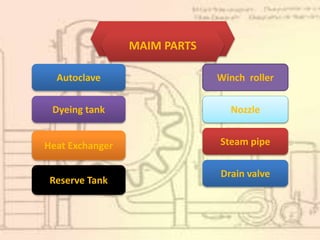

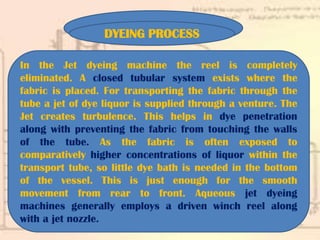

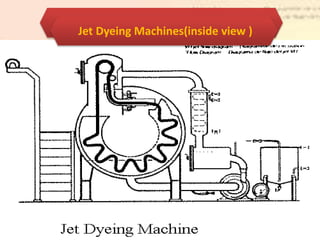

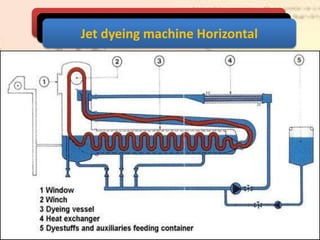

Jet dyeing machines are used to dye fabric in rope form, primarily polyester using disperse dyes. The fabric moves continuously in a loop through the machine, similar to winch dyeing. Jet dyeing machines aim to minimize drawbacks of earlier machines like winch and beam dyeing. Dyeing time is short, production is high, and water and dye liquor consumption is low compared to other machines. The jet of dye liquor creates turbulence to aid dye penetration while gently handling the fabric. Main parts include a dyeing tank, winch roller, nozzle, and heat exchanger. The dyeing process involves placing fabric in a closed tubular system and using a jet of dye liquor to transport the fabric through while