This document provides information about jet dyeing machines used for dyeing polyester fabrics with disperse dyes. It discusses:

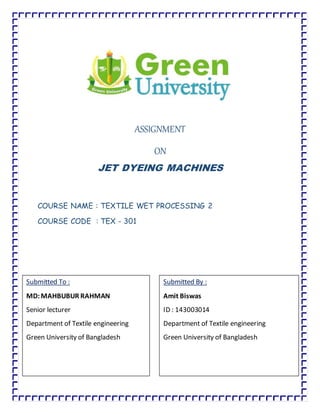

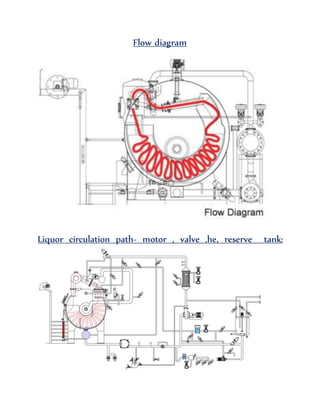

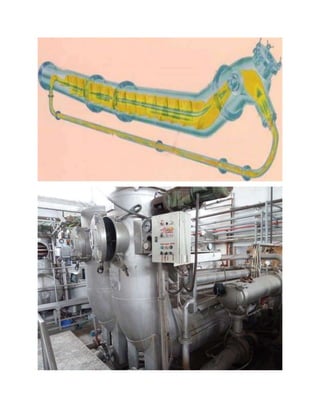

- Jet dyeing machines dye fabric in rope form inside a heated tube where jets of dye solution are forced through under pressure.

- The dye tank contains disperse dye, dispersing agents, leveling agents, and acetic acid which are heated and pumped through a nozzle into the tubular chamber holding the rotating fabric.

- Jet dyeing allows for high temperatures and pressures, low liquor ratios, gentle fabric handling, and reduces creasing compared to beam dyeing. However, it risks fabric entanglement and requires high costs and maintenance.