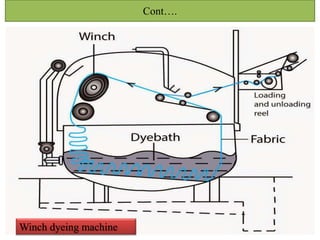

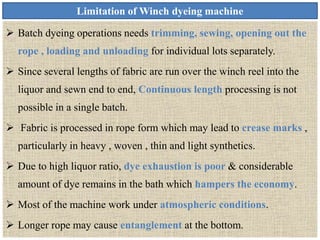

Winch dyeing machine is the oldest form of piece dyeing machine where fabric is dyed in rope form with stationary liquor and moving material. It is suitable for delicate fabrics like wool and knits due to low tension. The fabric is formed into endless loops and passed over rollers with most of it submerged in the dye bath. It allows for simple and low-cost dyeing but has limitations like batch processing and potential for creasing in heavier fabrics.