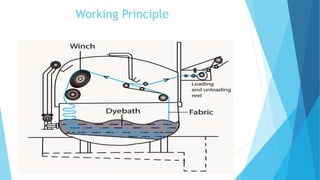

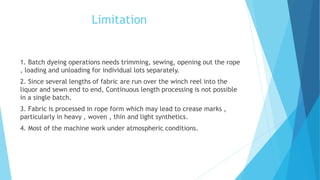

The winch dyeing machine is an older type of piece dyeing machine that is suitable for dyeing light fabrics like wool, silk, and loosely woven cotton. It operates at temperatures up to 98°C with a high liquor ratio of 1:20 to 1:40. Multiple ropes of fabric are loaded into the dye bath in a folded, immersed state and passed over rollers with one free-rolling and the other powered to control the movement of the fabric rope through the stationary dye liquor. While simple to construct and operate, it can only process fabrics in batches and is not suitable for continuous dyeing due to the need to sew ropes of fabric end to end.