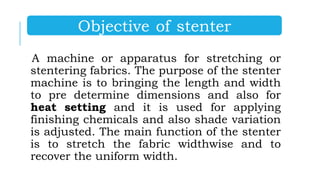

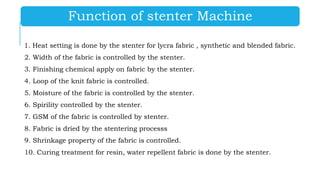

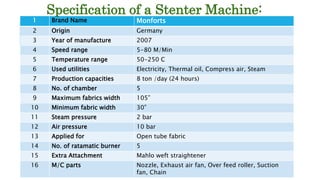

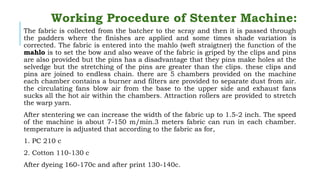

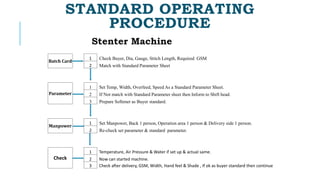

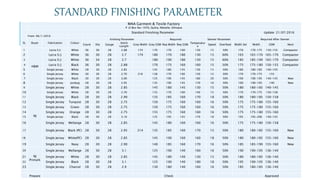

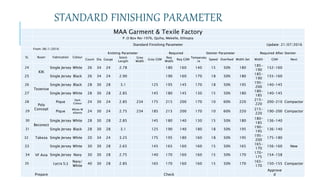

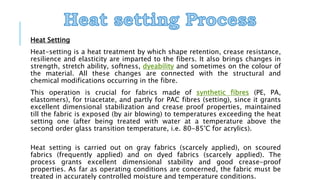

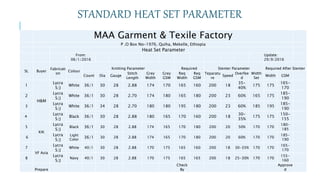

This document provides information about operating and setting heat parameters for a stenter machine at MAA Garment & Textiles Factory in Ethiopia. It discusses the objective of using a stenter machine to control fabric dimensions, apply heat setting and finishing chemicals. It then lists functions of the stenter machine like heat setting, width control, and moisture control. Details are given about a specific stenter machine brand and its specifications. The document concludes with standard heat setting parameters for different buyers and fabric types.