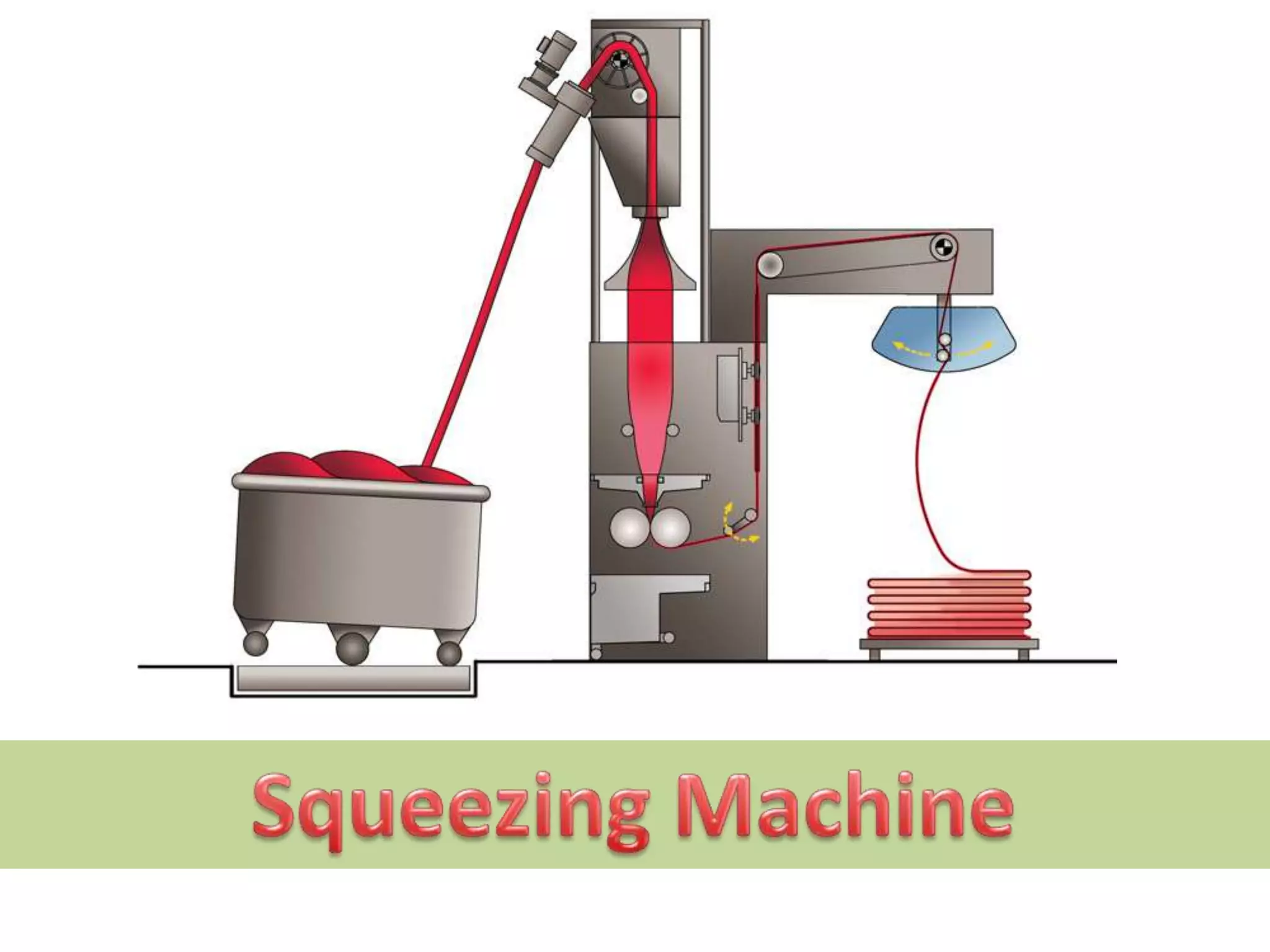

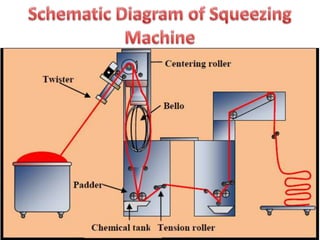

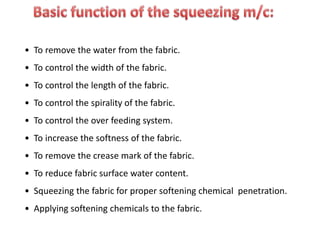

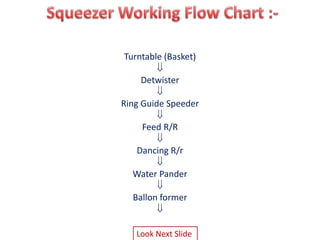

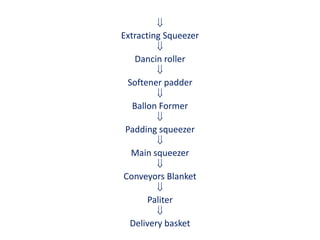

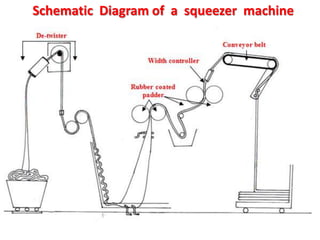

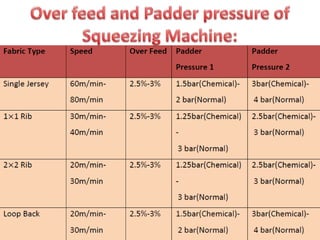

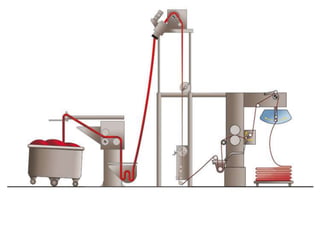

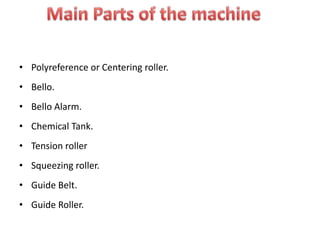

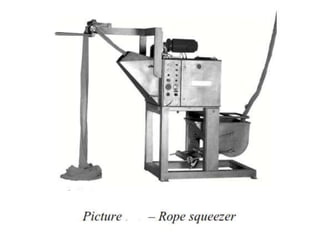

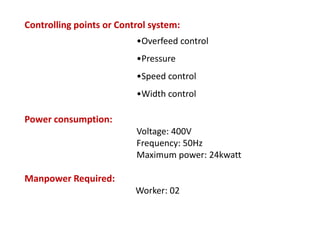

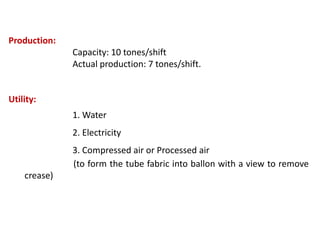

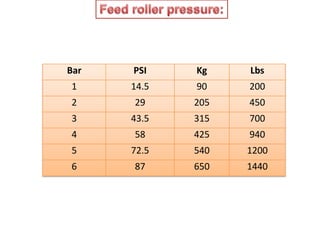

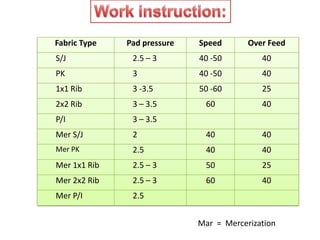

The document discusses a squeezer machine used in textile wet processing to extract water from fabrics after dyeing. It describes the machine's components and functions, which include removing water, controlling fabric width, length, spirality, and applying softening chemicals. It provides specifications of a particular machine, operating parameters for different fabric types, and discusses best practices and potential limitations.