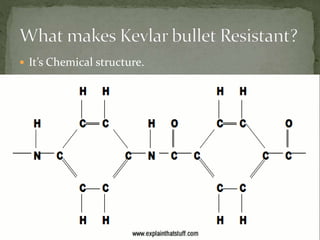

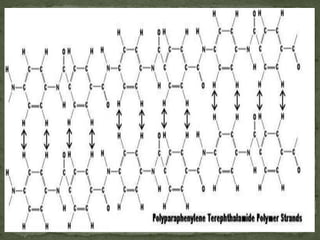

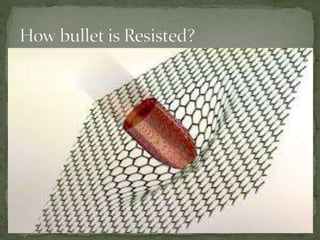

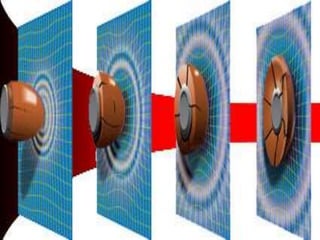

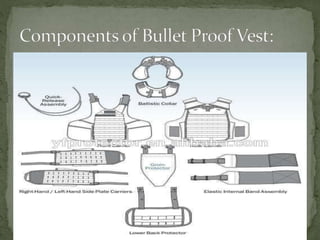

A ballistic vest, also known as a bullet-resistant vest, is designed to absorb impact and protect against projectiles from firearms and shrapnel. The most commonly used material is Kevlar, which is often blended with natural fibers to enhance durability and performance. Vests can vary in layers and are tailored for different users such as police, security personnel, and military forces based on the level of protection required.