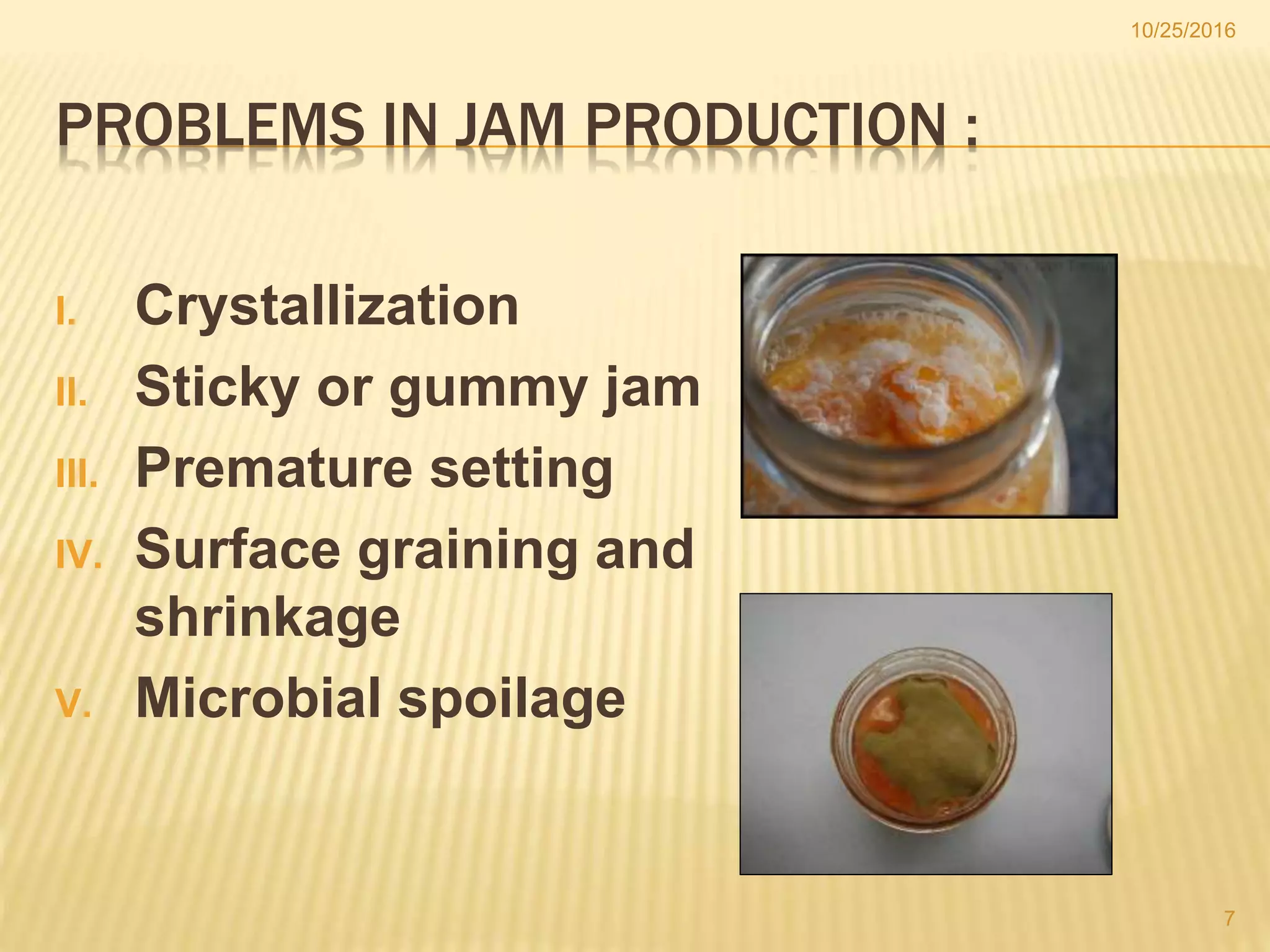

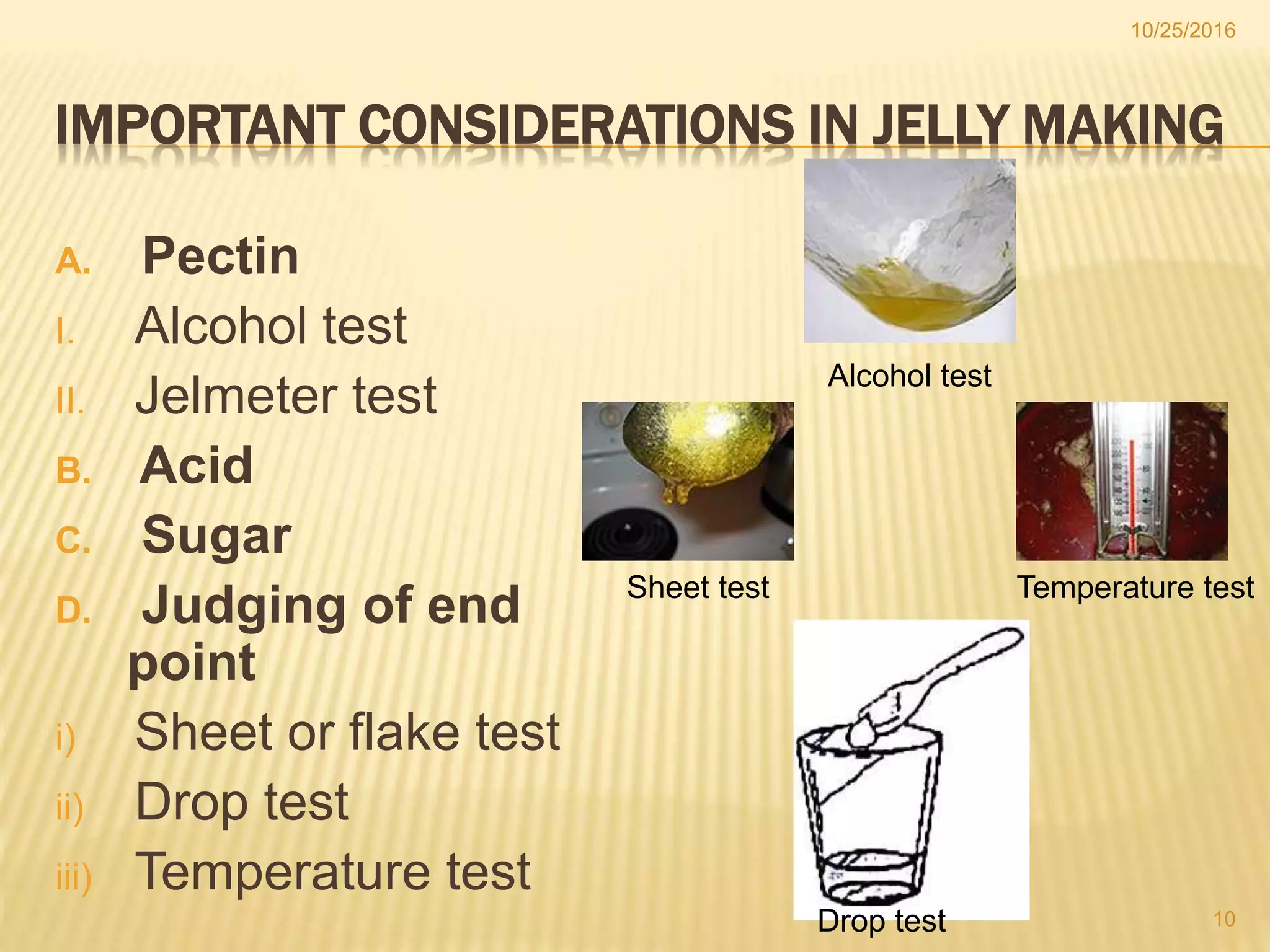

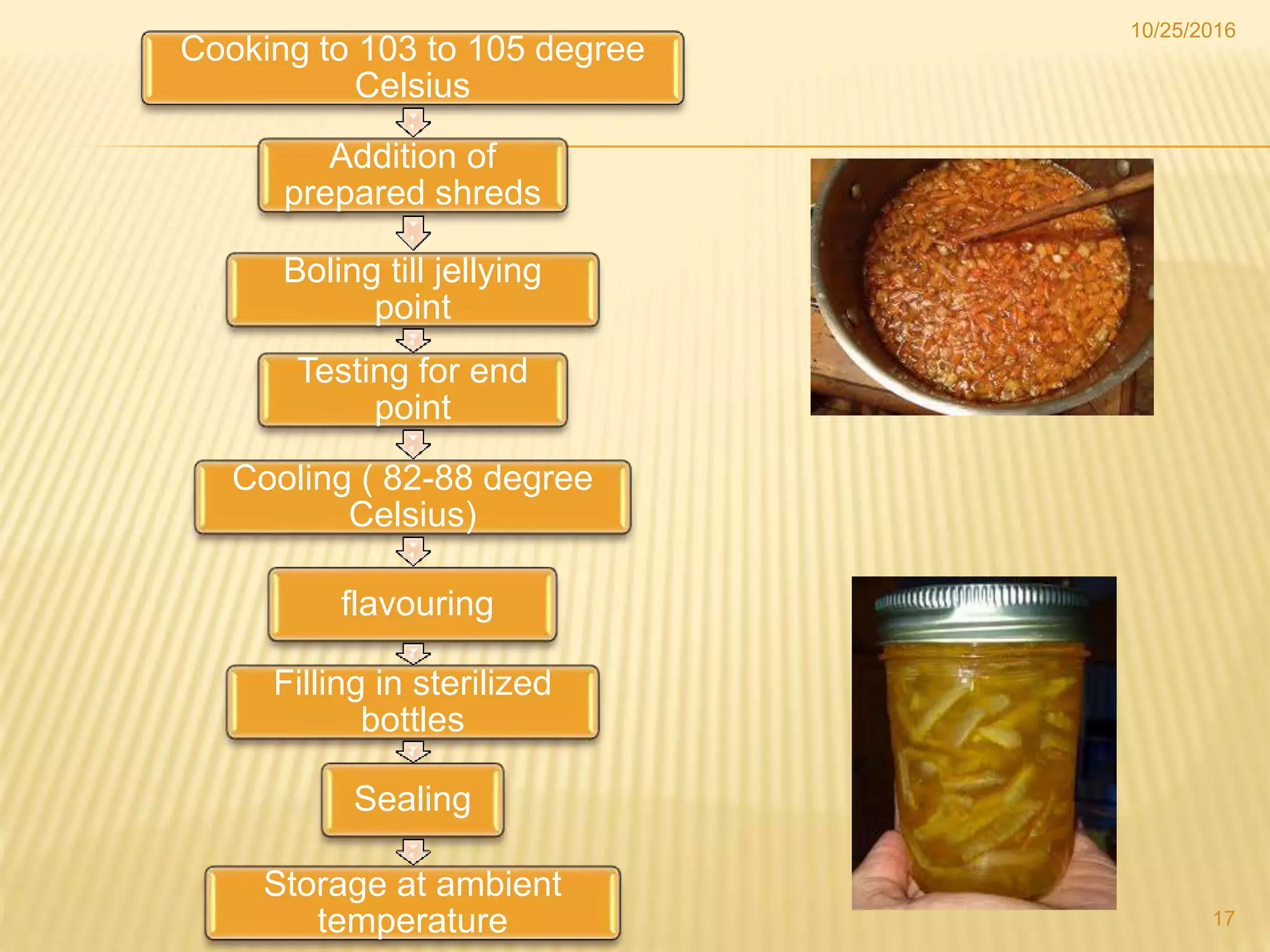

Jam, jelly, and marmalade are prepared from fruits and vegetables. Jam is made by boiling fruit pulp with sugar until thick. Jelly is made from boiling fruit extract, sugar, and acid until set. Marmalade contains shreds of citrus peel suspended in a jam-like mixture. The document provides recipes and instructions for producing jam, jelly, and marmalade at home or commercially. Key steps include washing, peeling, boiling fruit with sugar and acid, and testing for proper thickness or set before filling into containers.