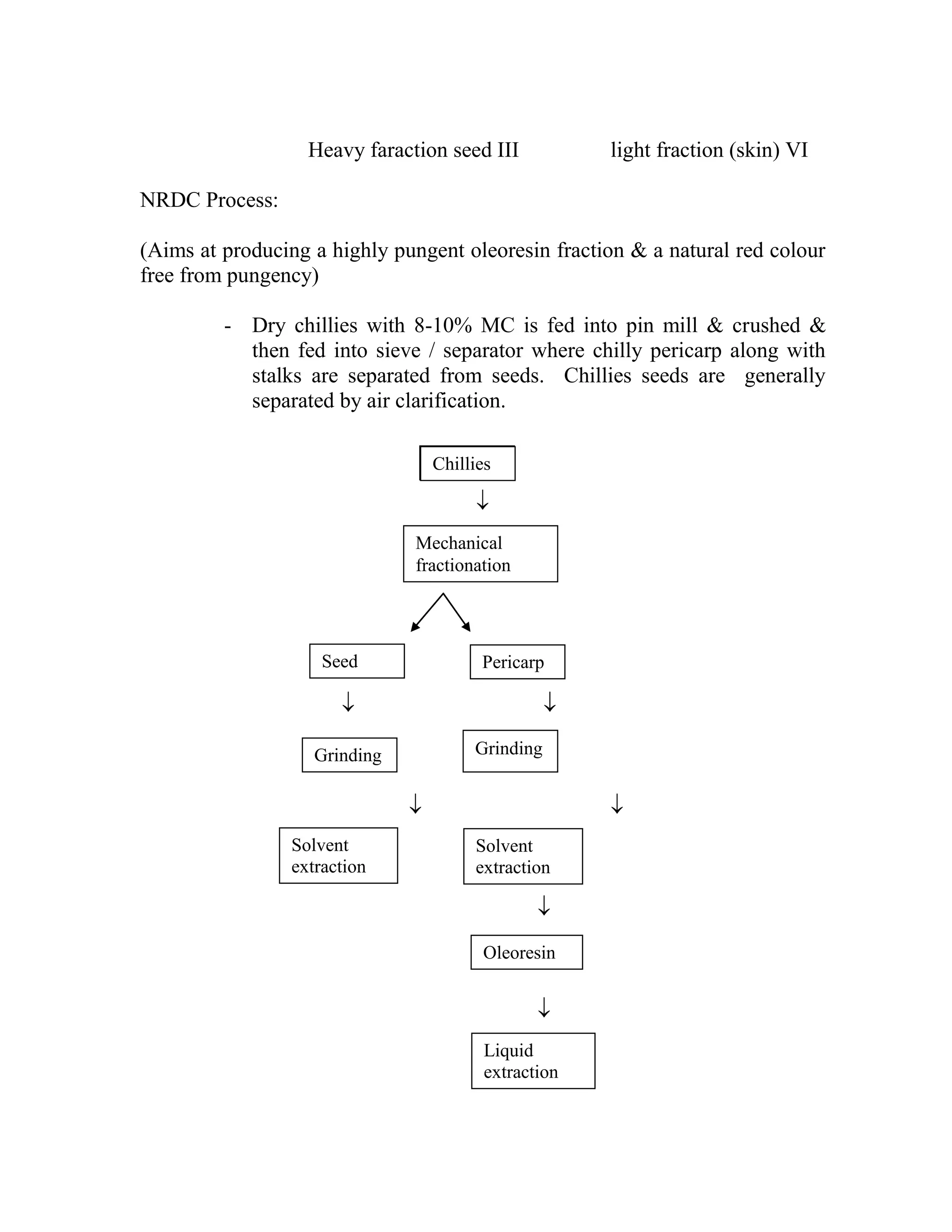

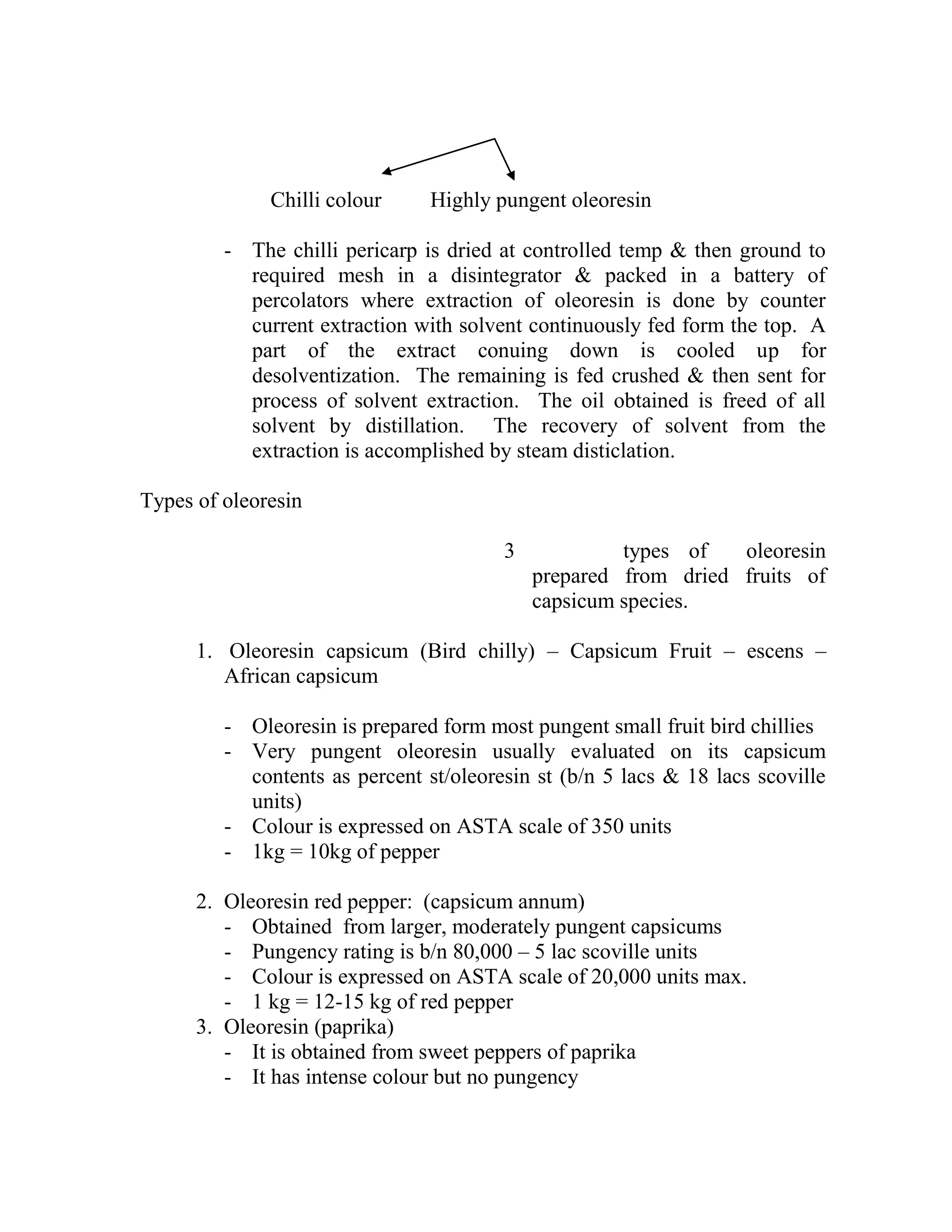

This document provides information about processing of spices and plantation crops. It discusses the history of spice production in India, value addition processes for spices like grinding and extraction of essential oils and oleoresins. Some common spices produced in India like black pepper, ginger and turmeric are described in terms of the value added products that can be made from them. The functions, nutritional importance and classification of spices are also summarized.

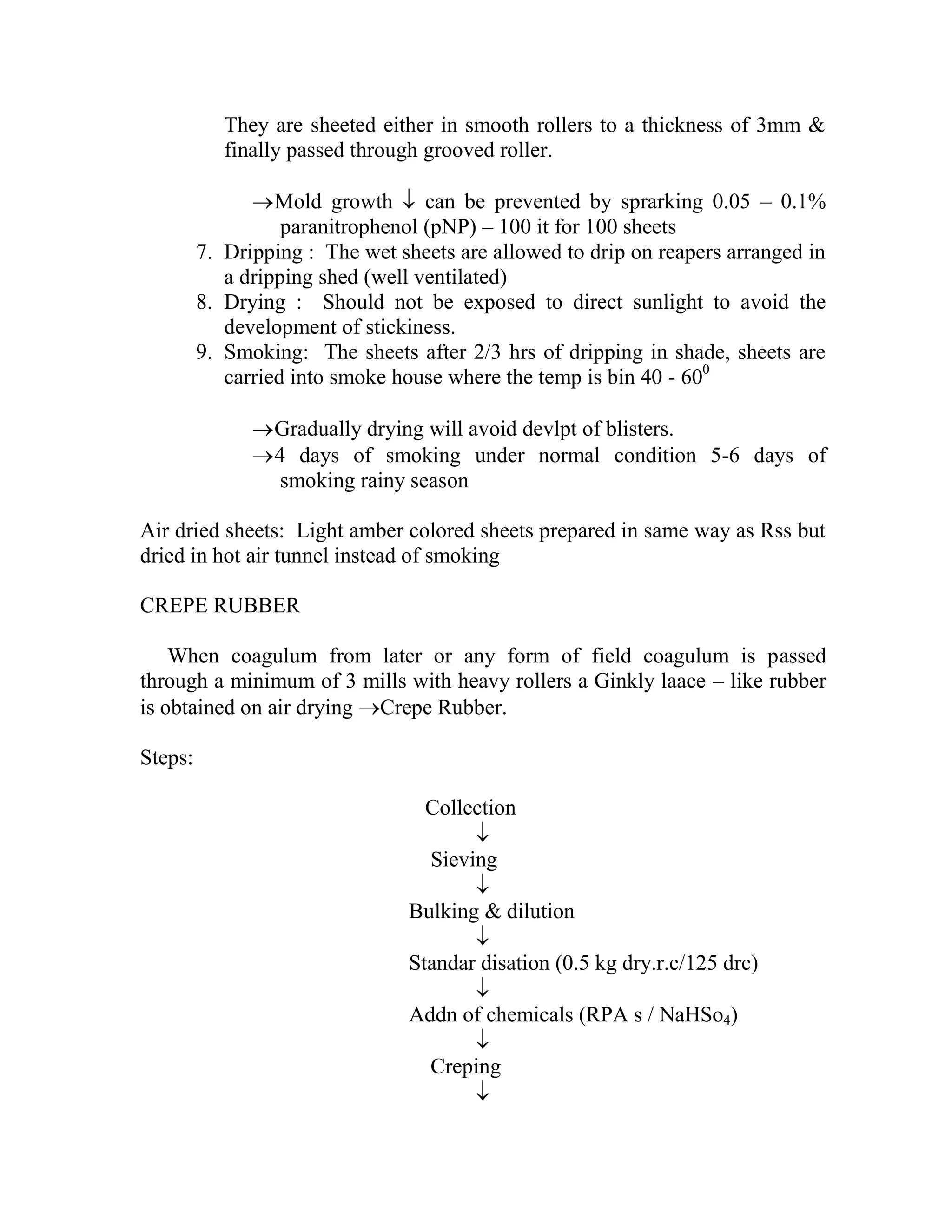

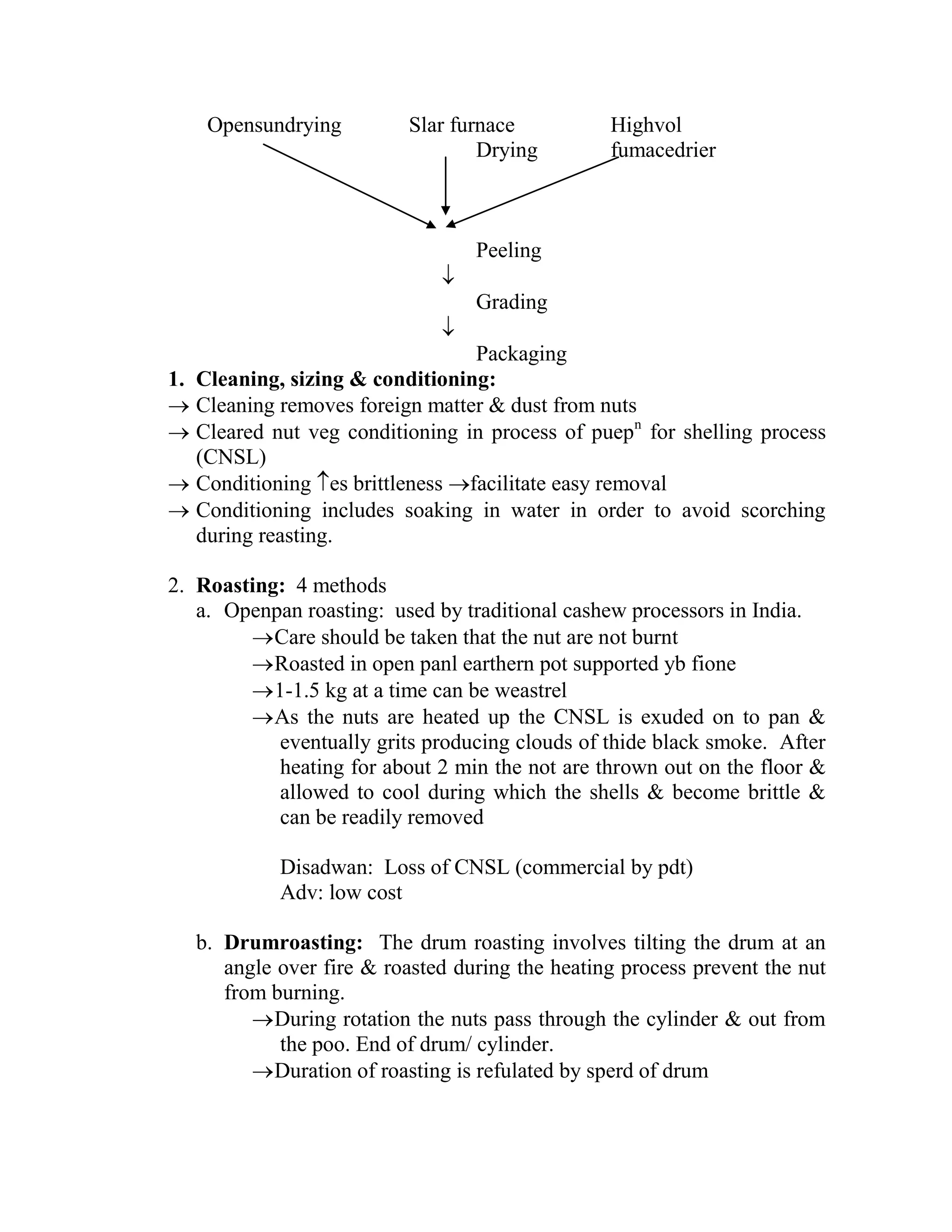

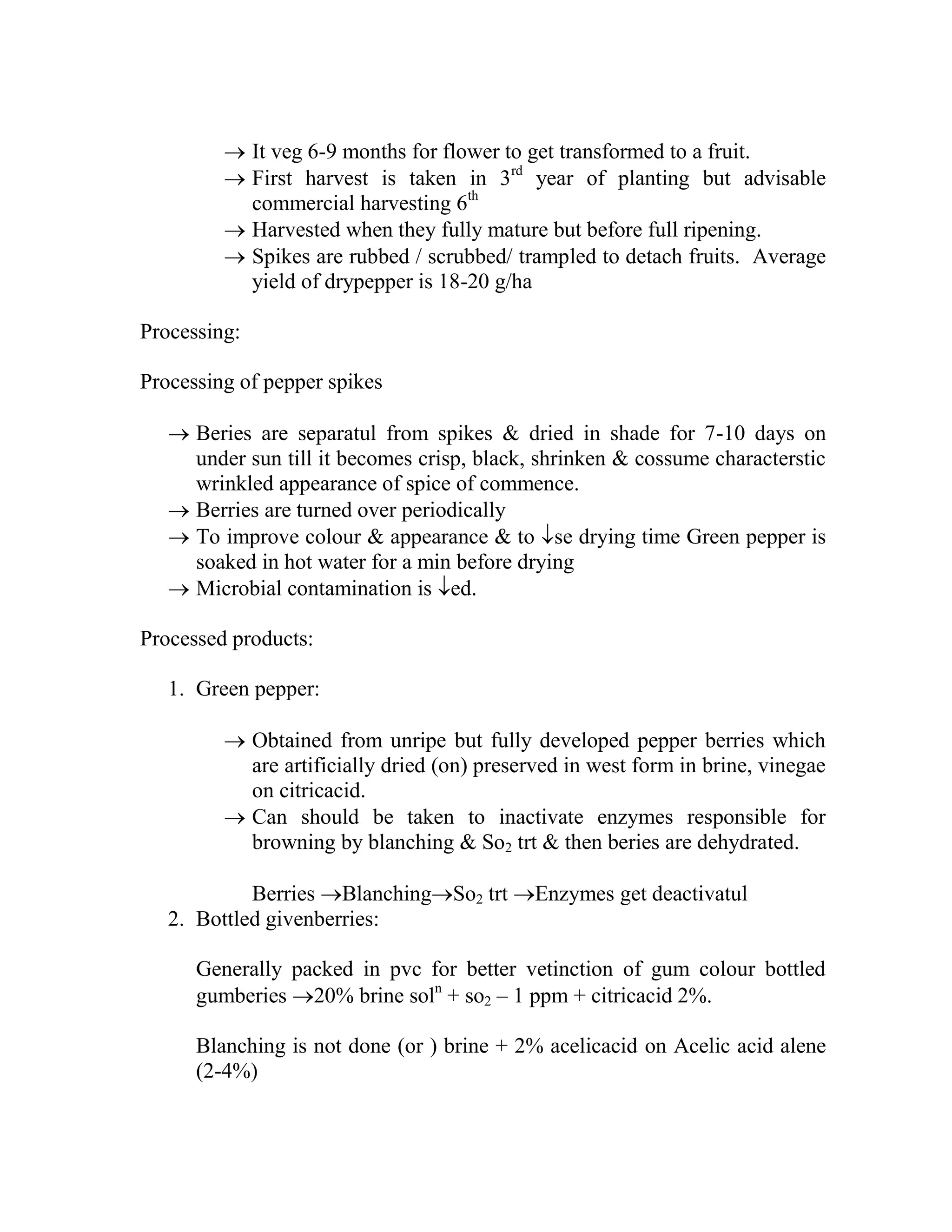

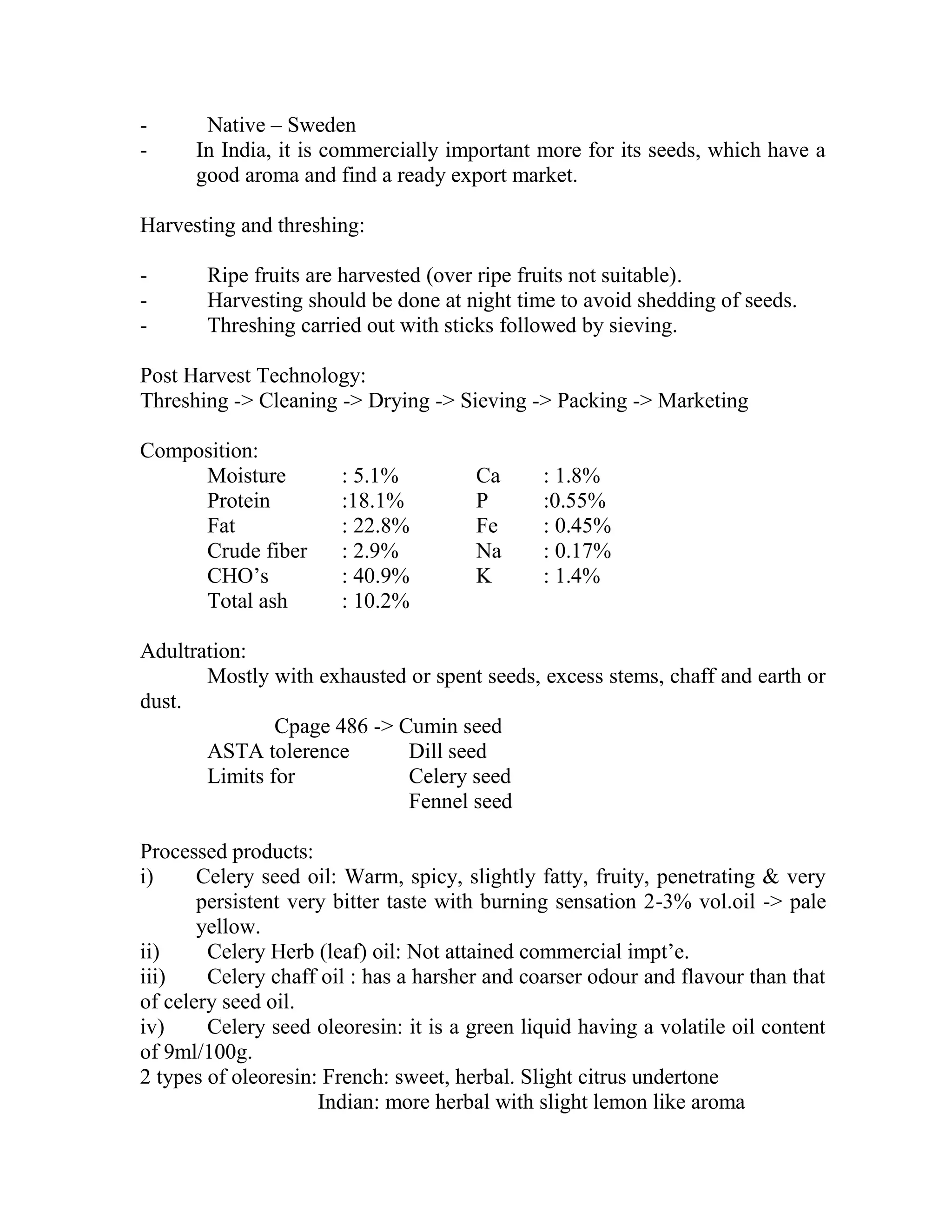

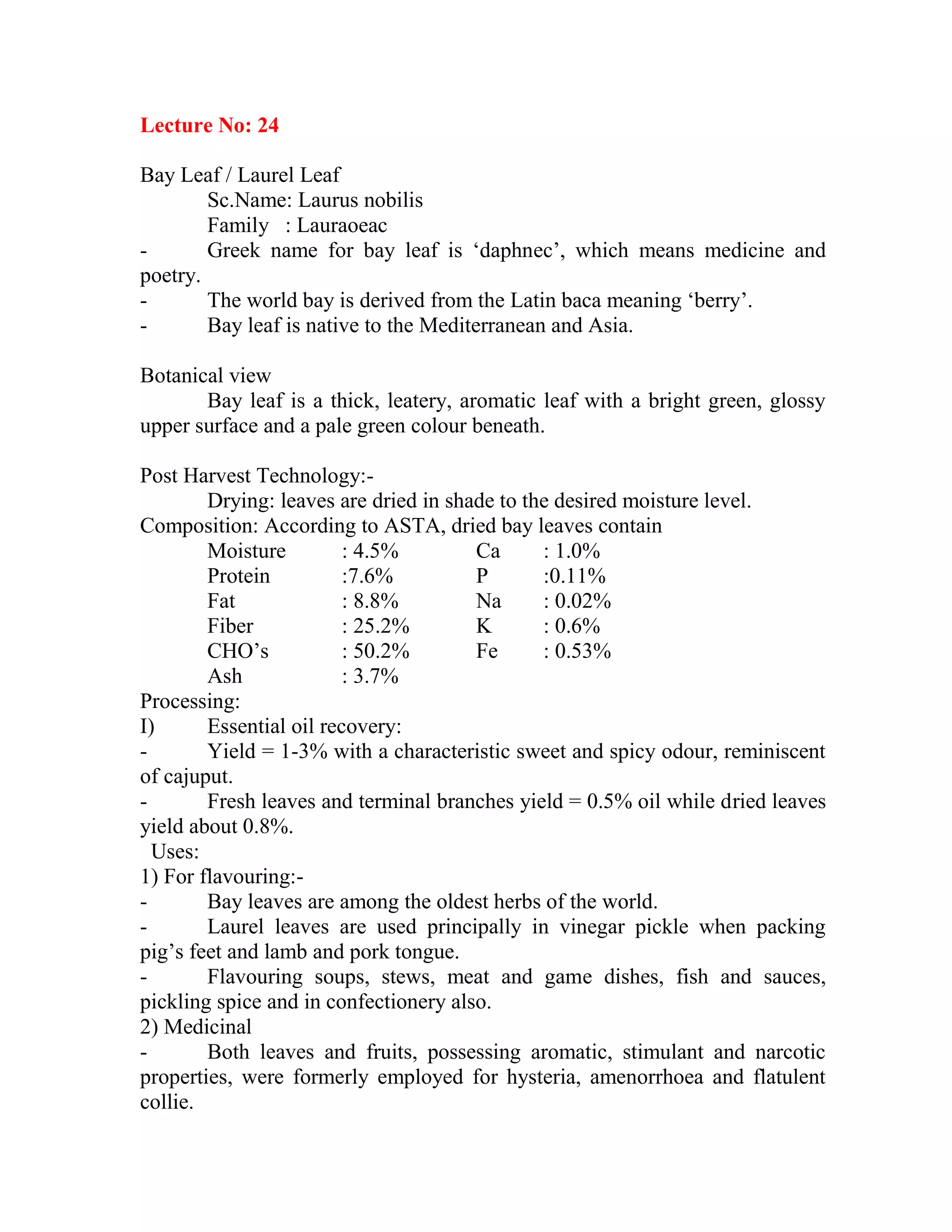

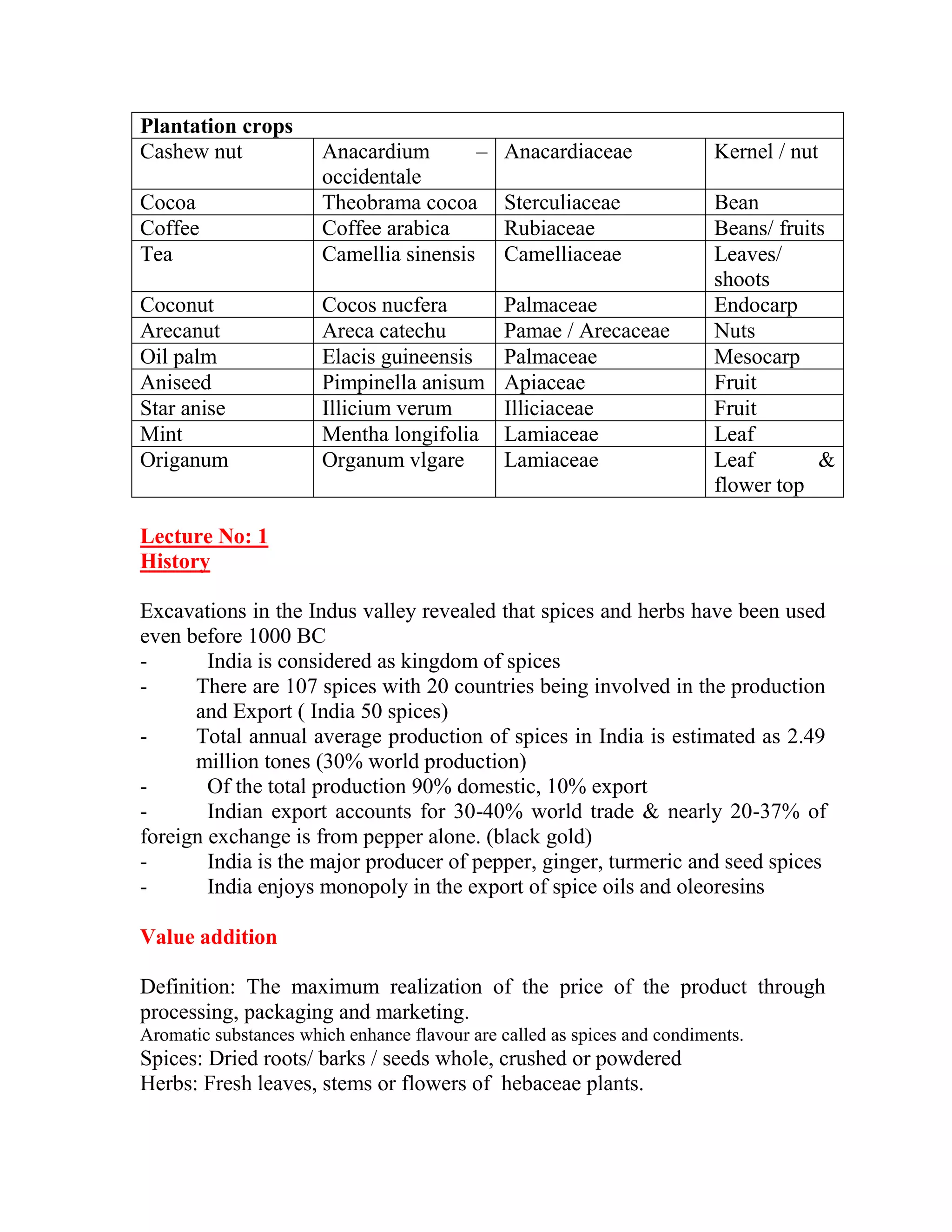

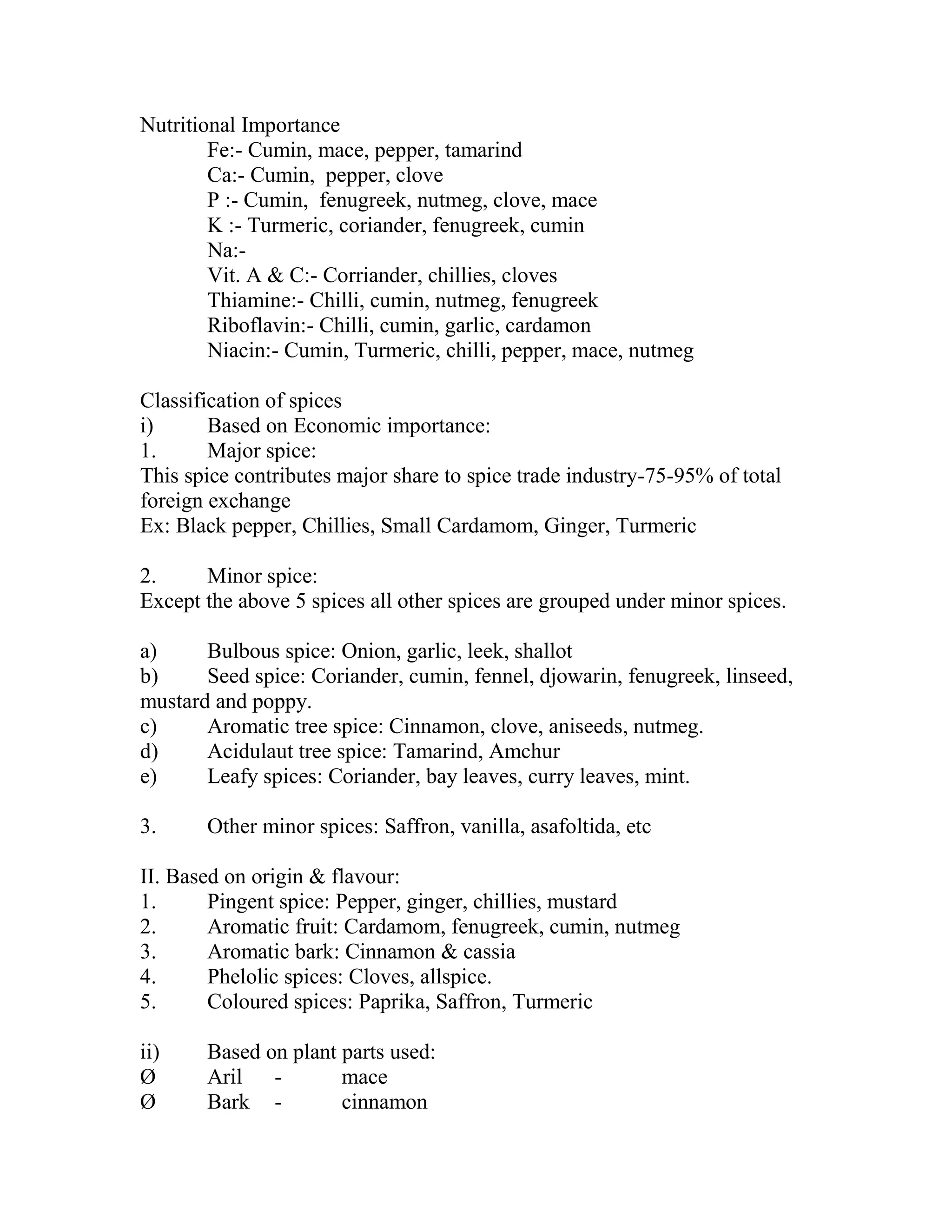

![Ø Beny - black pepper

Ø Buds - clove

Ø Bulbs - onion, garlic

Ø Floral parts- saffron

Ø Pods - tamarind, vanilla

Ø Fruits - cardamom

Ø Kernels - nutmeg

Ø Leaves - mint/ coriander, bay, curry

Ø Rhizomes - ginger, turmeric

Ø Latex - safetida

Ø Roots - horse radish

Ø Seeds - fenugreek, mustard, cumin

IV Based on climatic requirements:

1. Tropical – High temperature and abundant pH

Eg:-Clove, Nutmeg, Cinnamon, Pepper, Ginger

2. Subtropical – 3 distinct seasons (winter, summer, mansoon)

i.e, Low Temp during – vegetatives

High temp during – reproductive / mo

Eg: Cumin : coriander, fenugreek, onion, garlic

Temperature:- Low temp/ frost conditions

Eg:- saffron, asfoetida

iii) Based on number of seasons:

iv) Annivals – 1 year/ 1 season [ life cycle]

Eg: Coriander, fenugreek, fennel, cumin

v) Biennial: life cycle – 2 seasons

Eg: Onion, parsley

vi) Perennials: More than 2 seasons

Eg: Black pepper (Herbaceous perennial)

Saffron ( Bulbous perennial)

Cloves

Cinnanon (woody perennial)](https://image.slidesharecdn.com/processingofspicesandplantationcrops-acharyangpdfdrive-210212151314/75/Processing-of-spices-and-plantation-crops-acharya-ng-pdf-drive-10-2048.jpg)