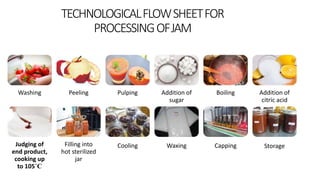

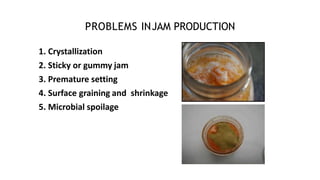

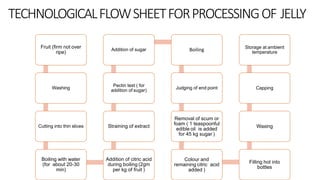

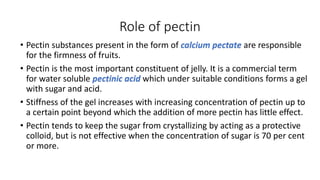

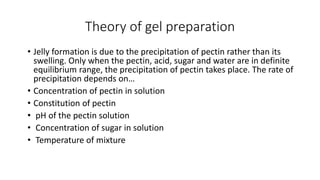

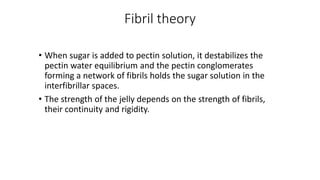

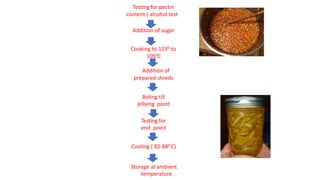

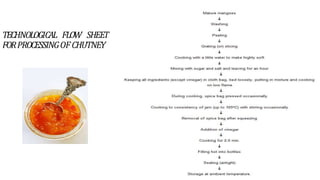

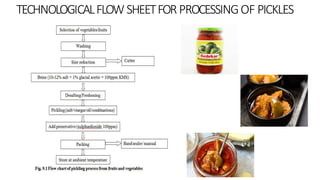

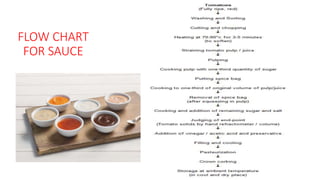

This document discusses various fruit and vegetable products including jam, jelly, marmalade, pickles, chutneys and sauces. It provides definitions, ingredients, and the technological processes for making each product. For jam, jelly and marmalade it describes the roles of pectin, theories of gel formation, and potential problems in production. Standard processes involve washing, peeling, boiling, adding sugar and acid, and filling into sterilized containers. Quality is ensured through testing viscosity, acidity, sugar content and sealing containers.