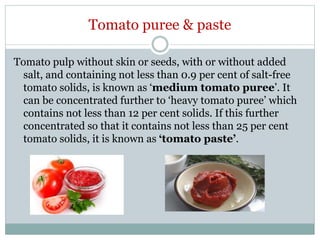

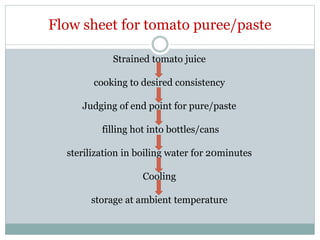

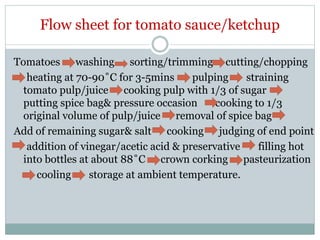

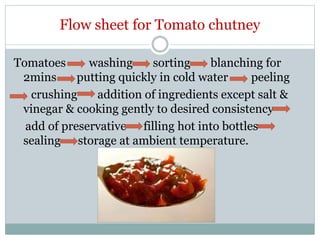

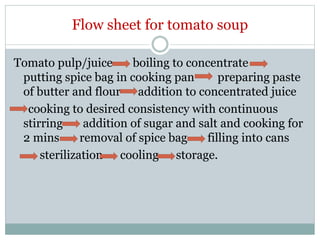

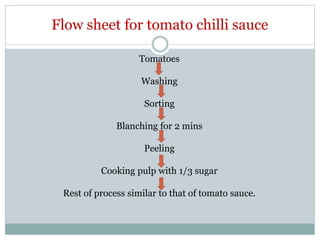

Tomatoes grown in winter have higher quality and are processed into products like juice, puree, paste, sauce and ketchup to avoid losses during peak seasons. Processing involves selecting fully ripe tomatoes, washing, sorting, cutting, heating and pulping them before adding other ingredients like salt, sugar and spices. The mixture is then filled into bottles or cans, sterilized and stored. Problems like black neck formation in bottles can be prevented by filling hot products above 85°C and reducing iron contamination.