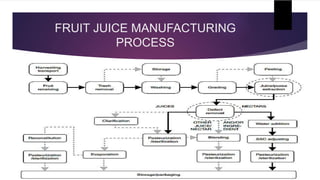

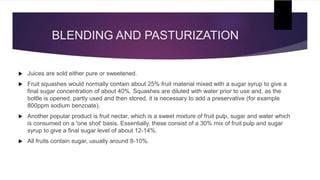

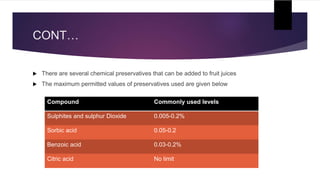

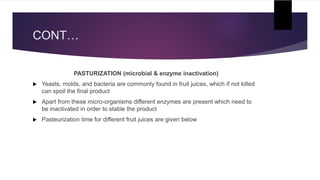

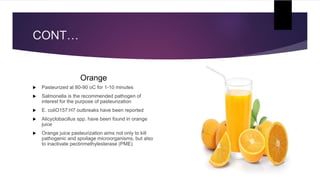

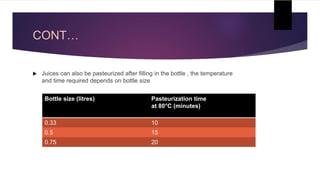

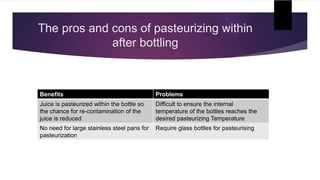

Fruit juices and drinks are produced through a process involving preparation of raw materials, juice extraction, filtration, blending, pasteurization, filling, sealing, and packaging. Key steps include washing and sorting fruit, juicing or pulping, clarification, addition of preservatives, hot-filling into sterilized bottles/containers, and labeling with required information before distribution. Pasteurization inactivates microbes and enzymes to improve shelf-life, with times varying depending on the type of fruit juice. Packaging materials include glass, PET, cans, and cartons.