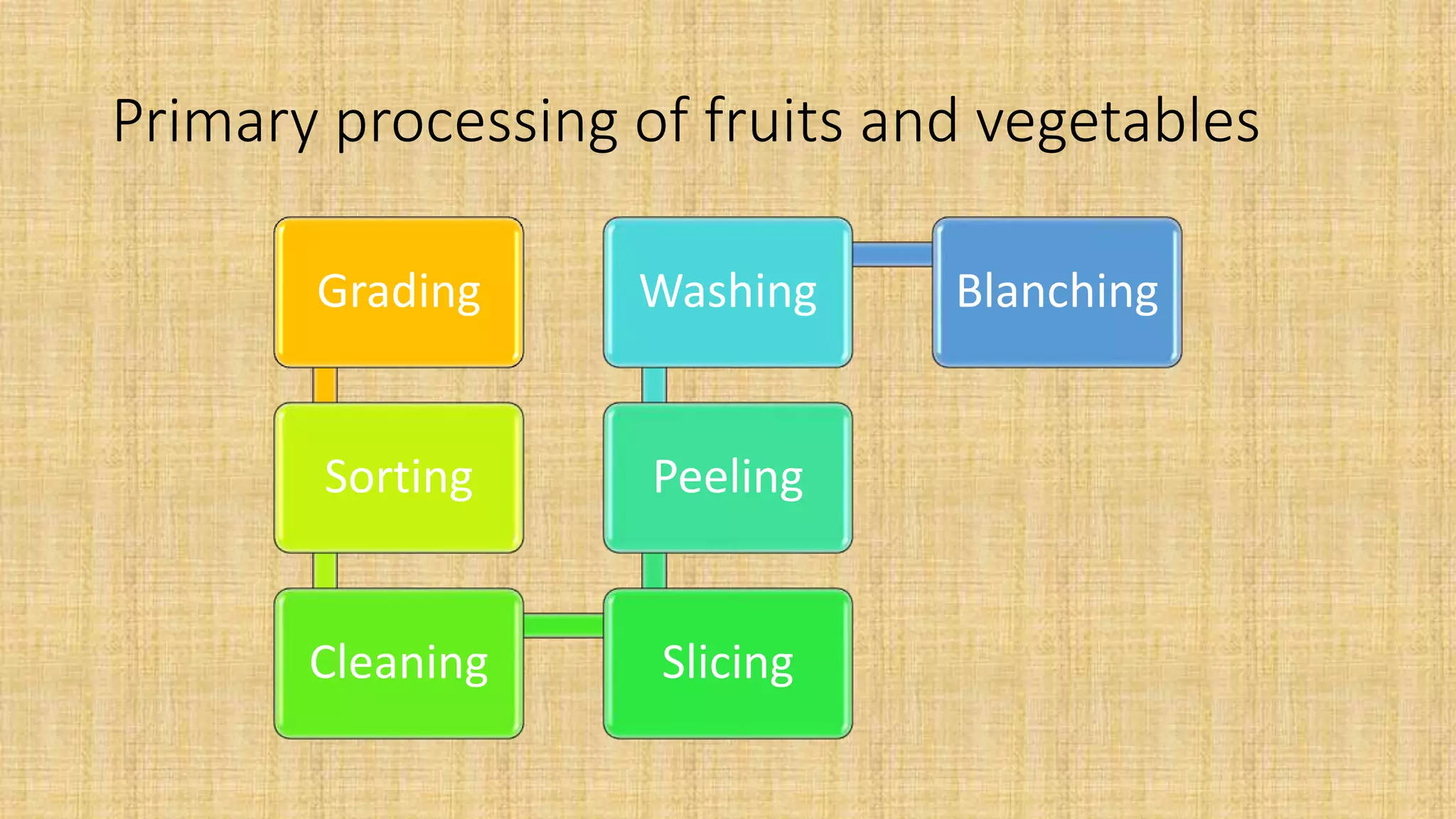

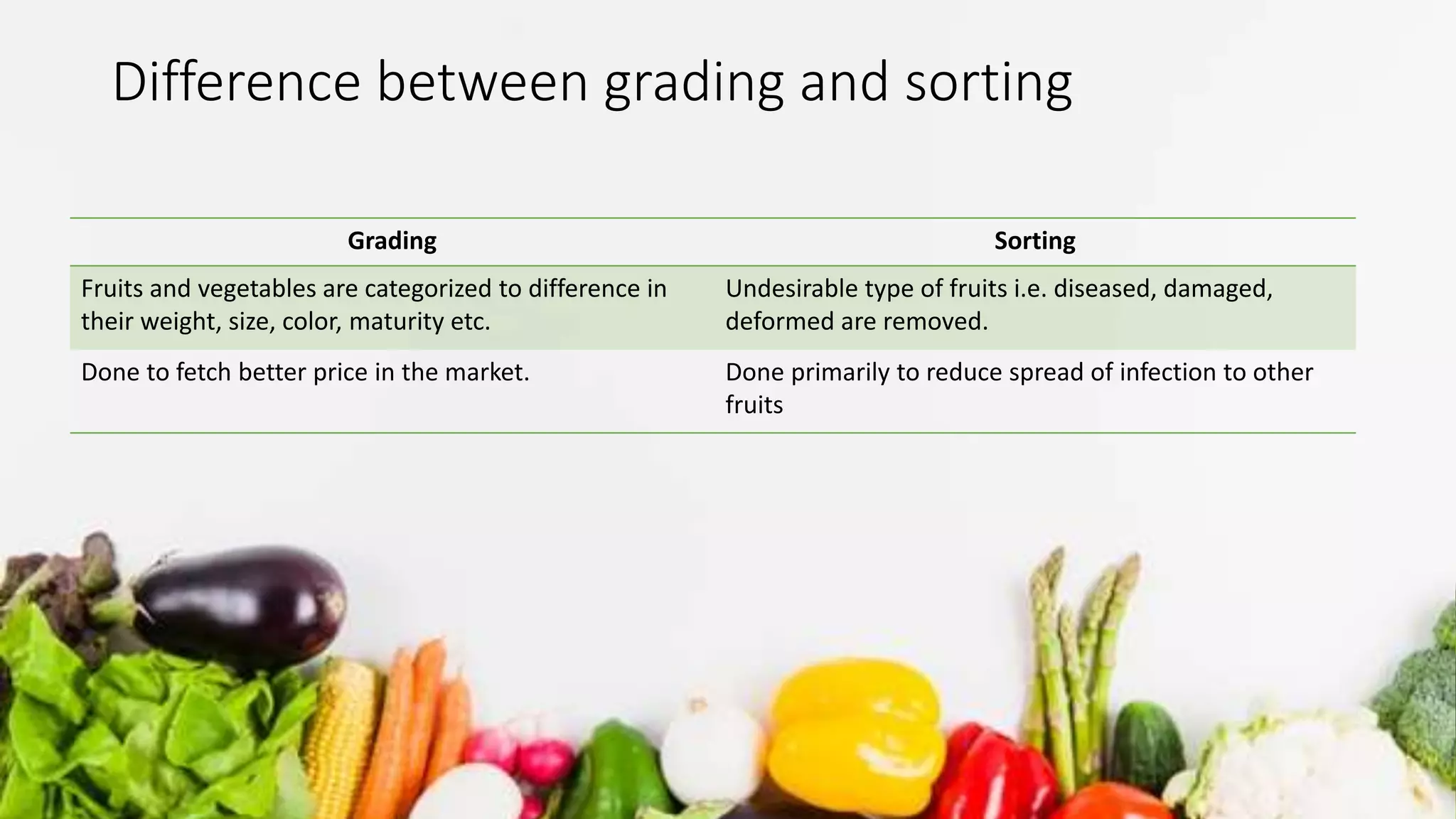

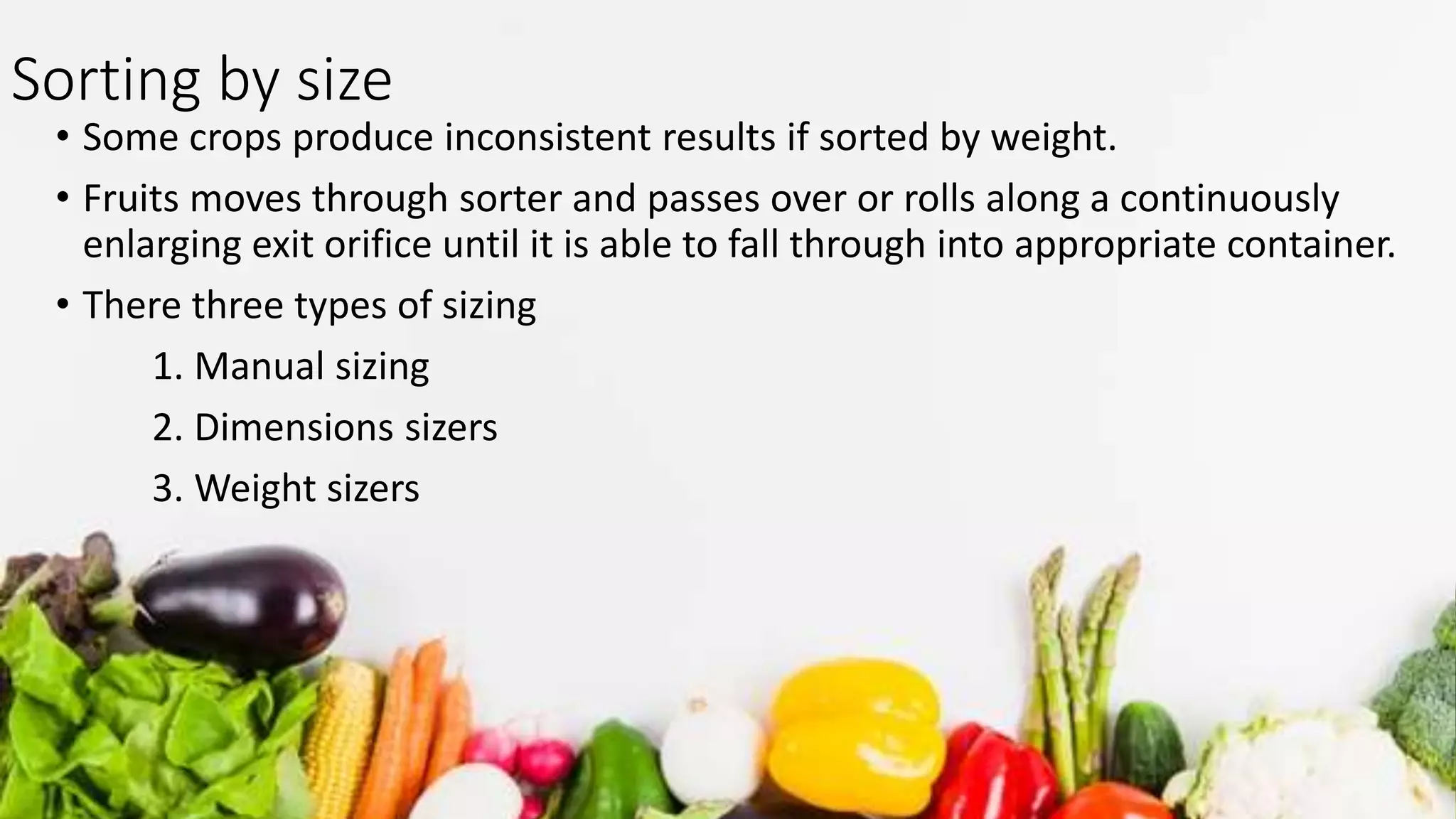

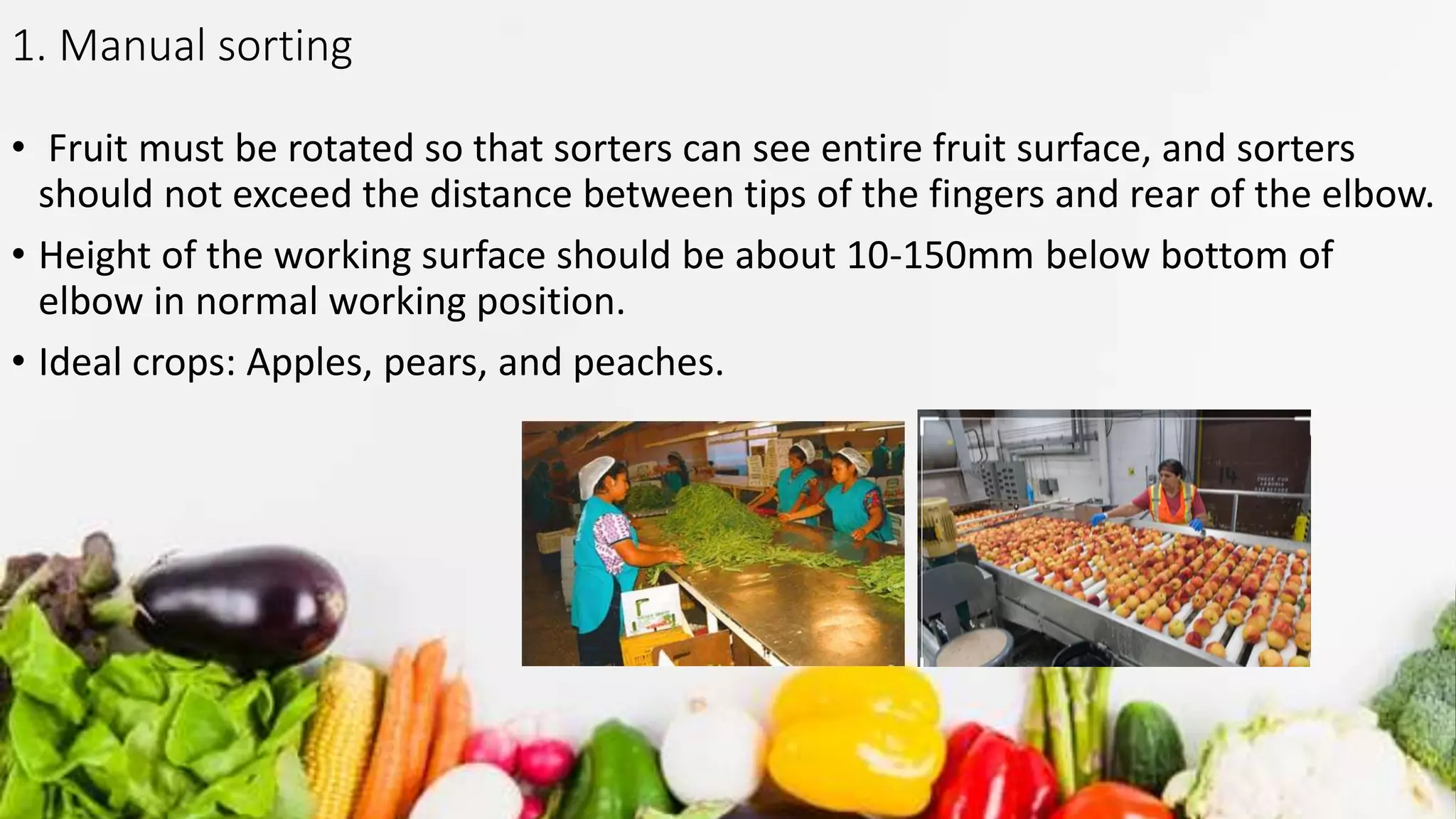

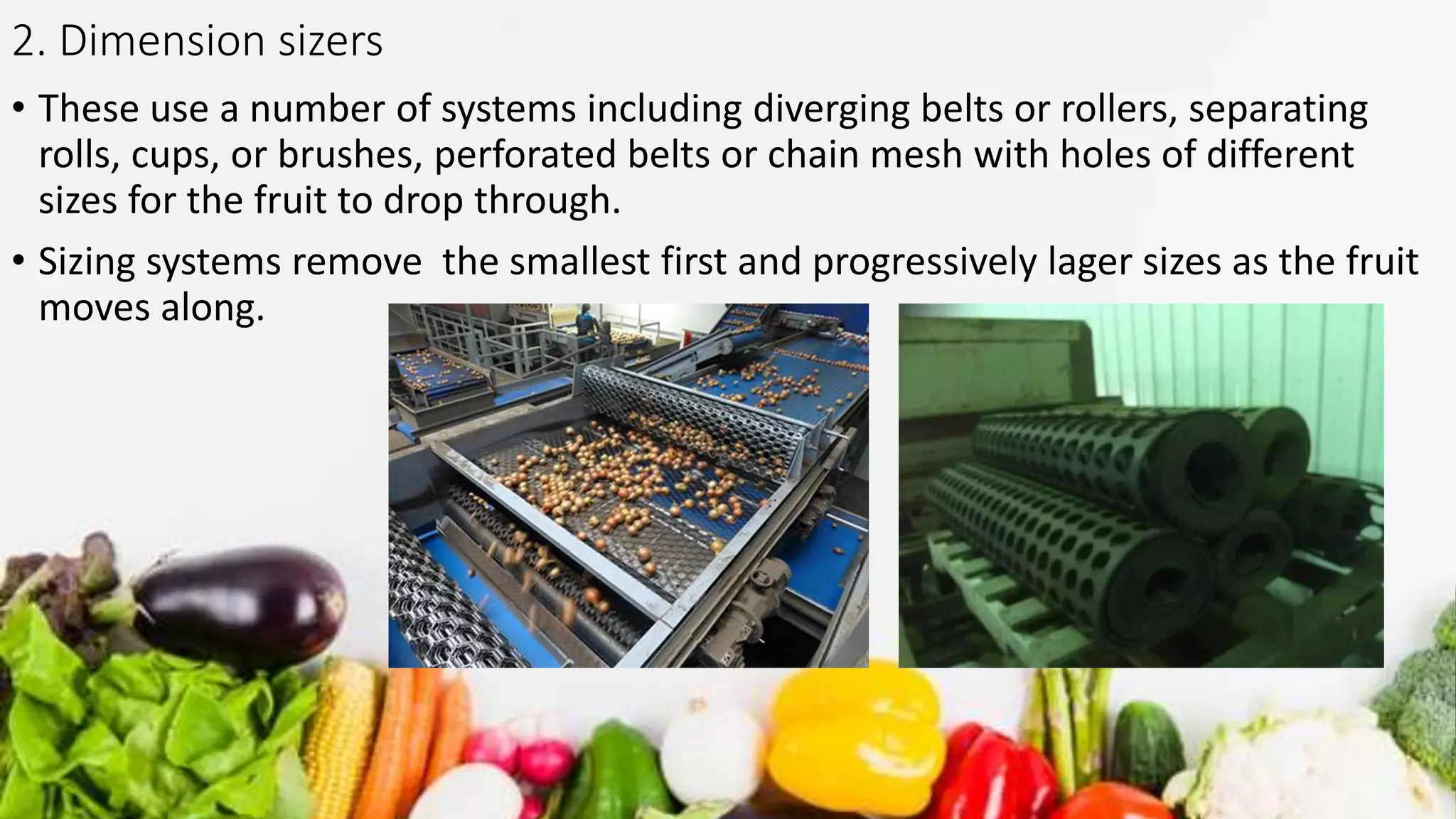

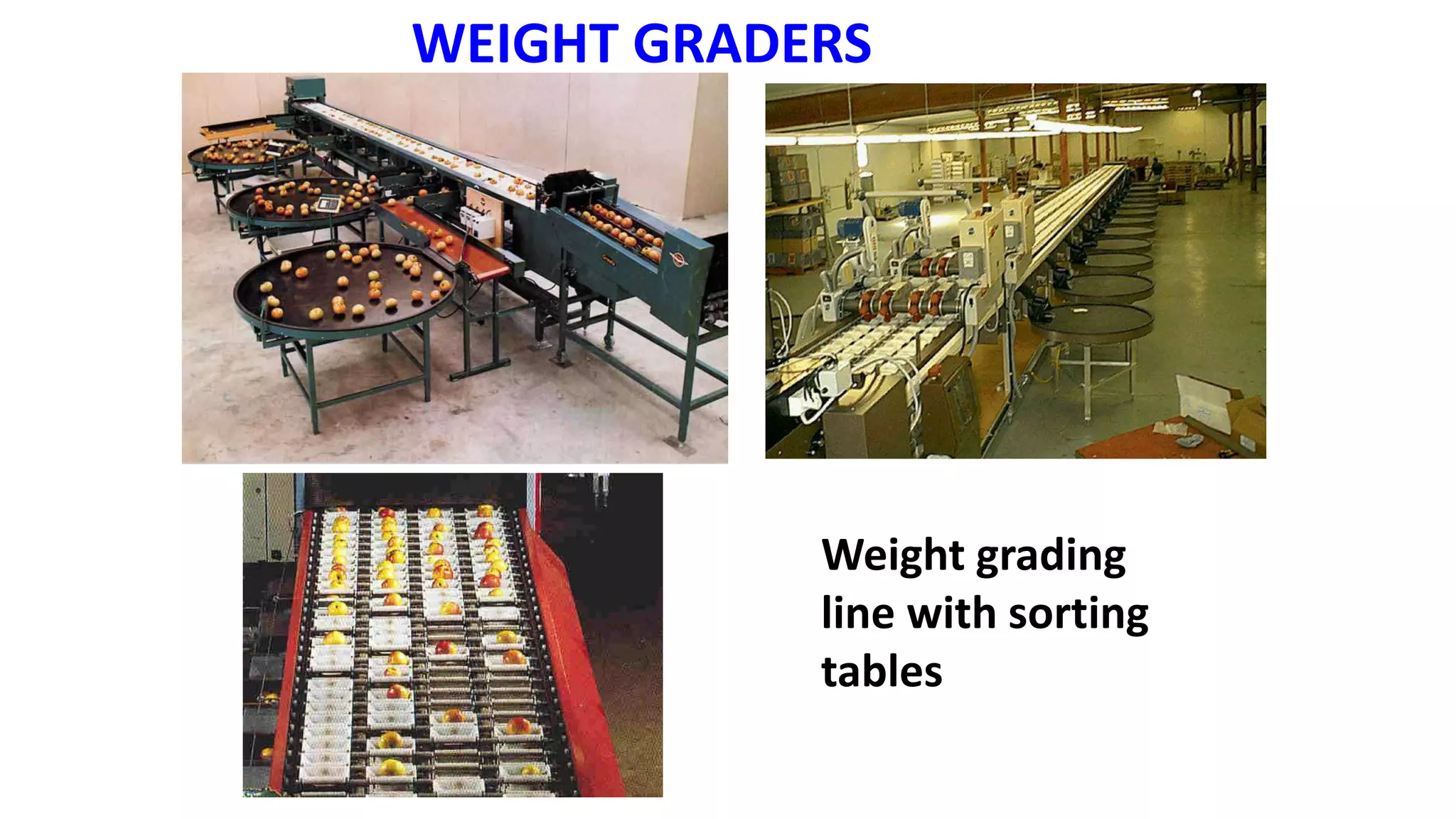

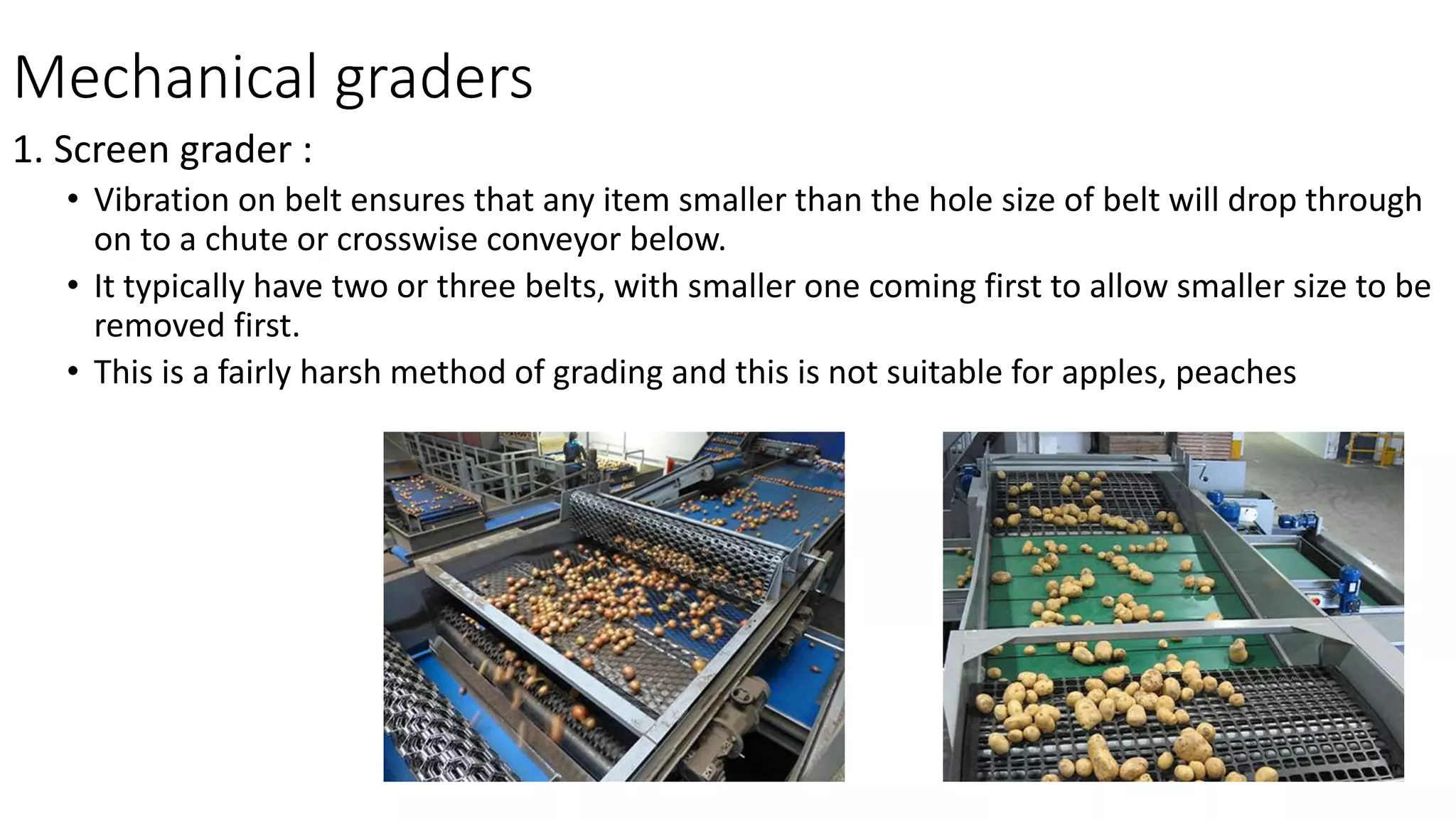

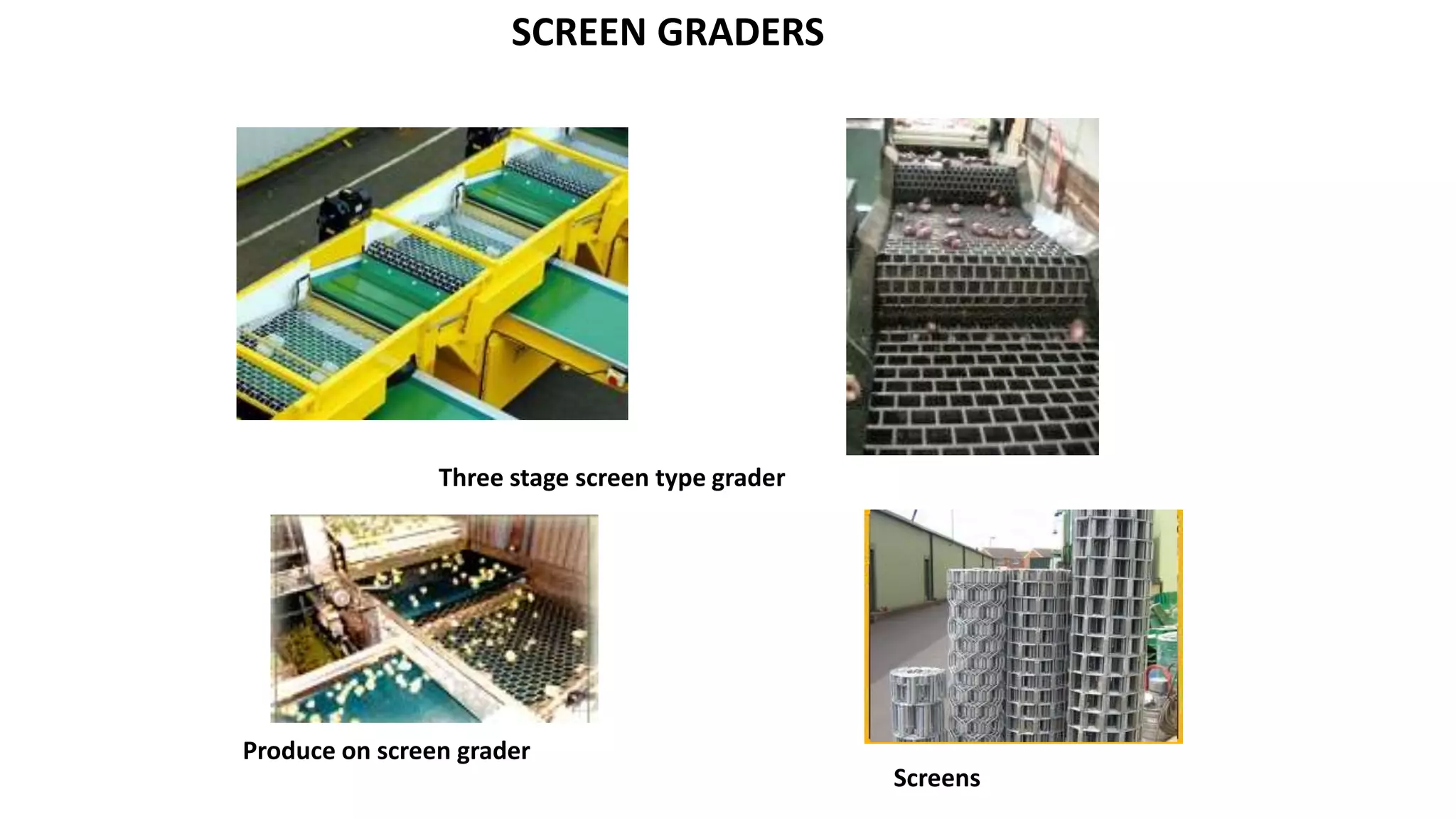

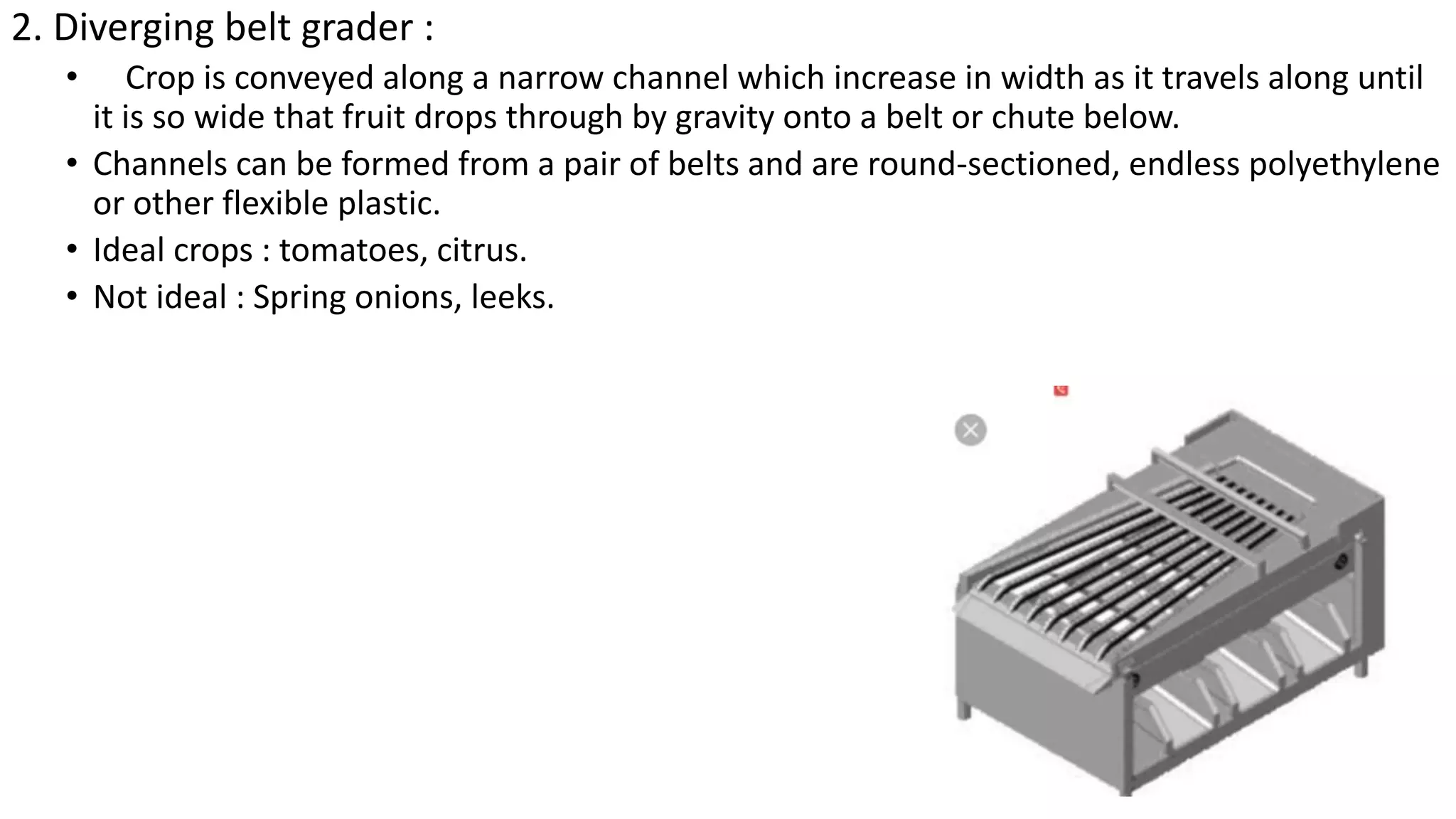

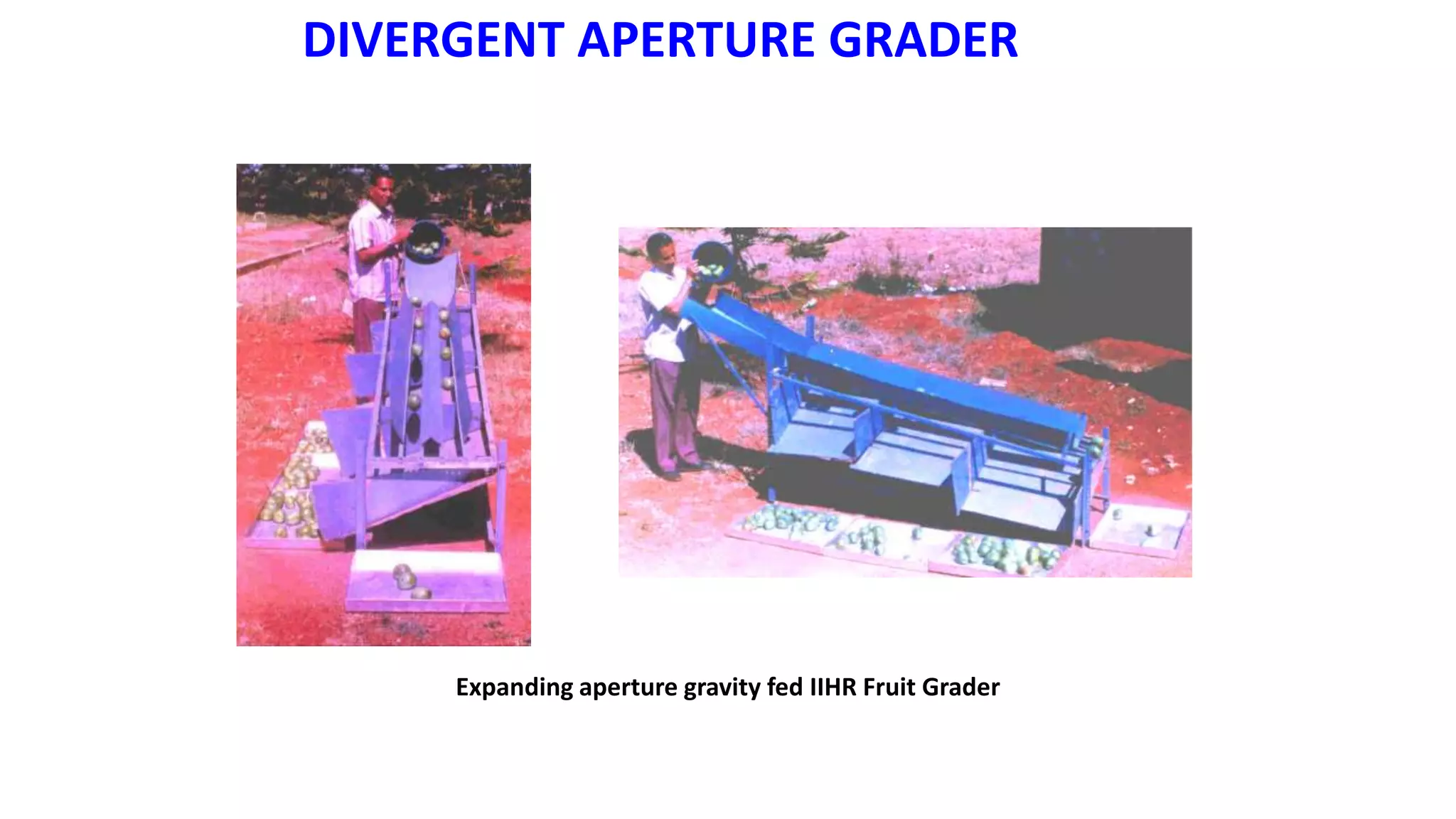

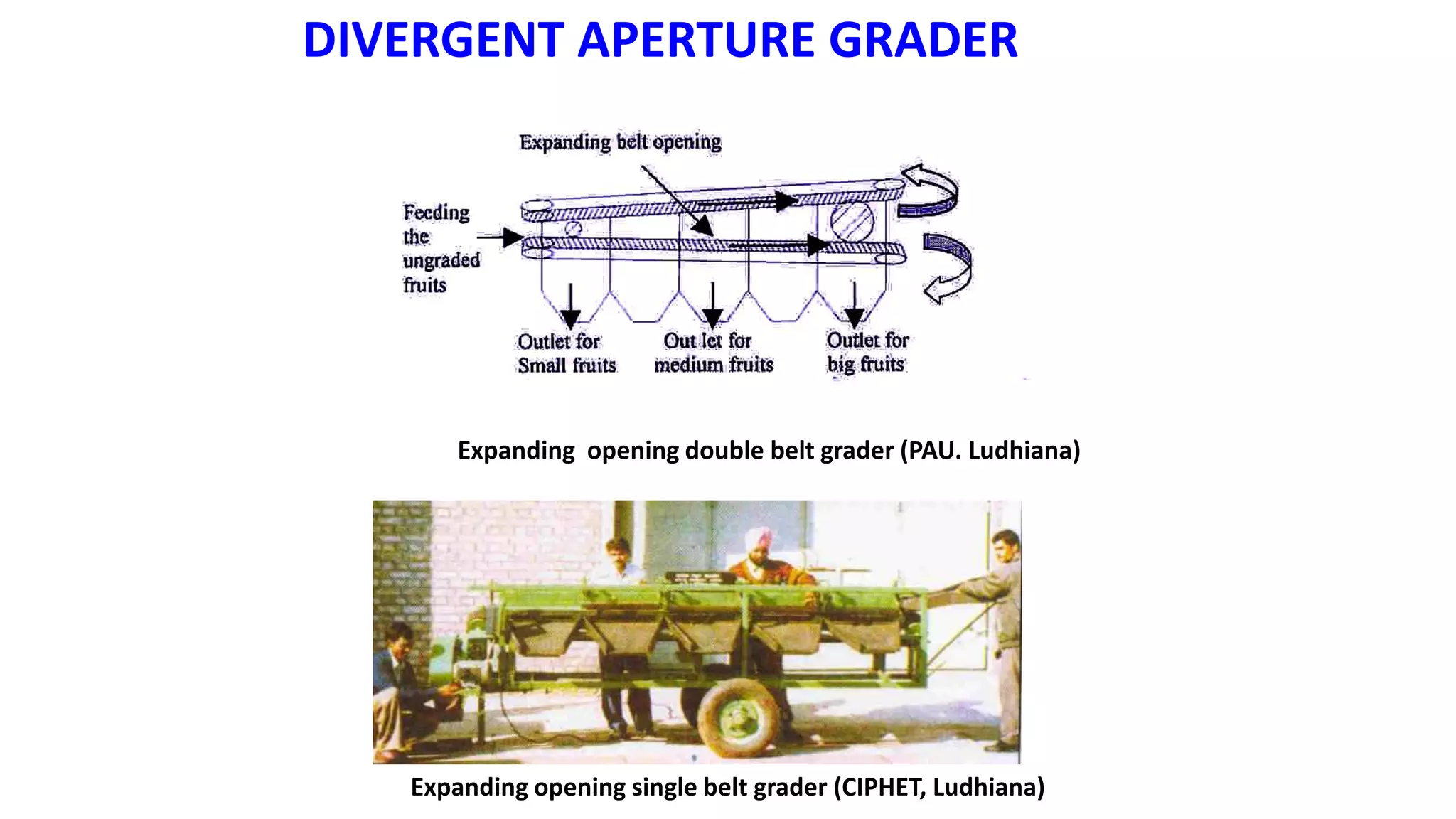

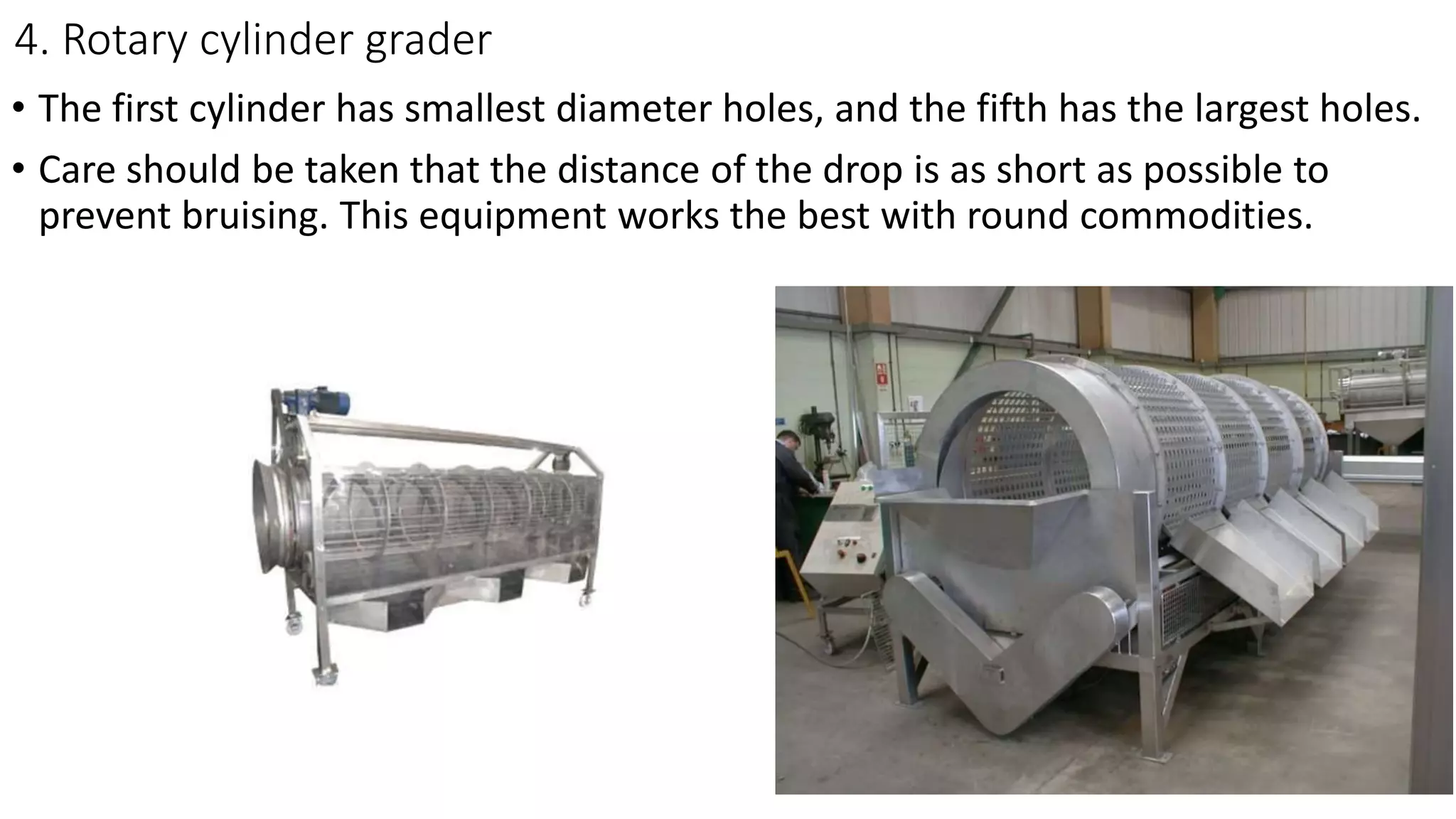

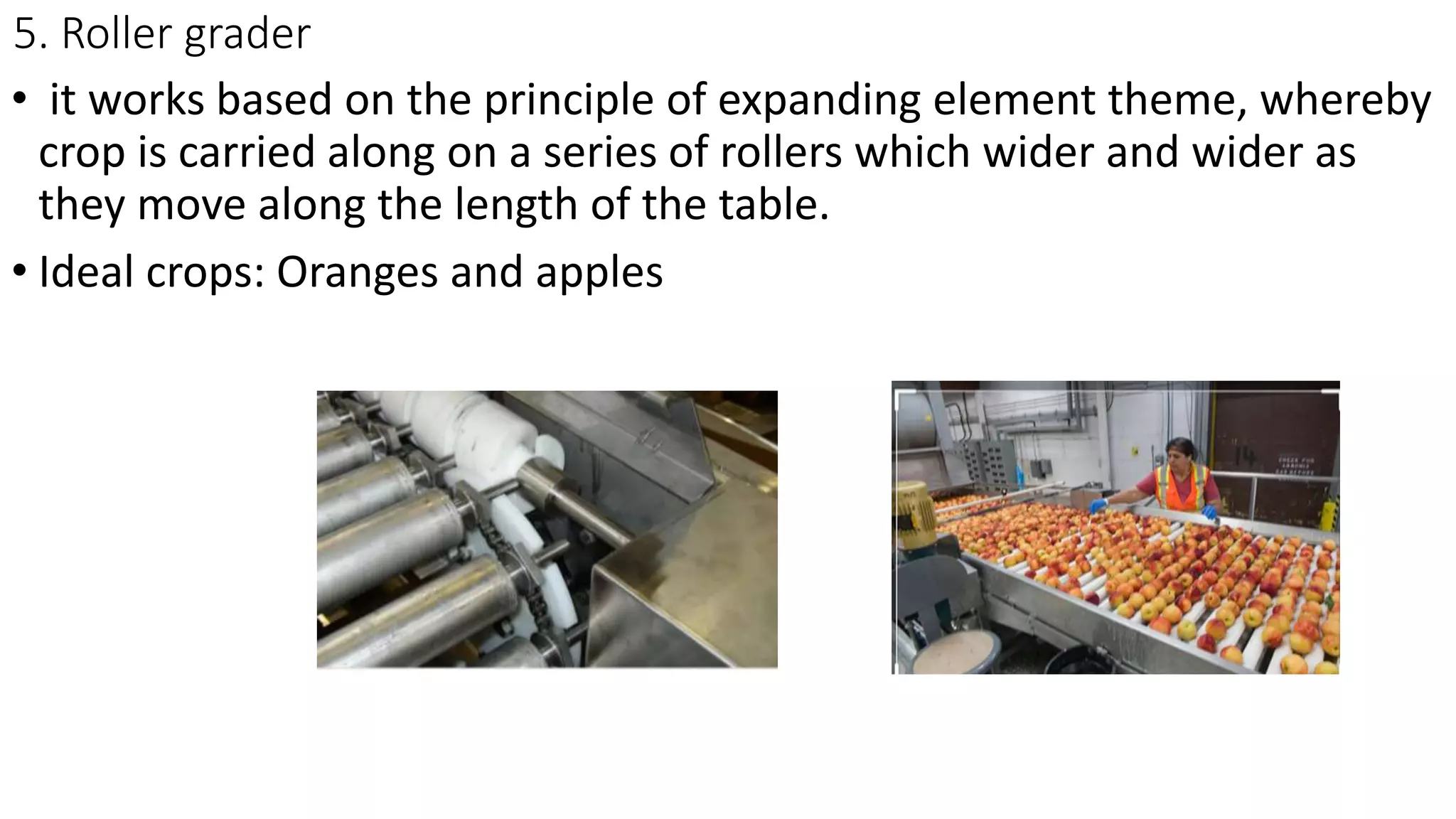

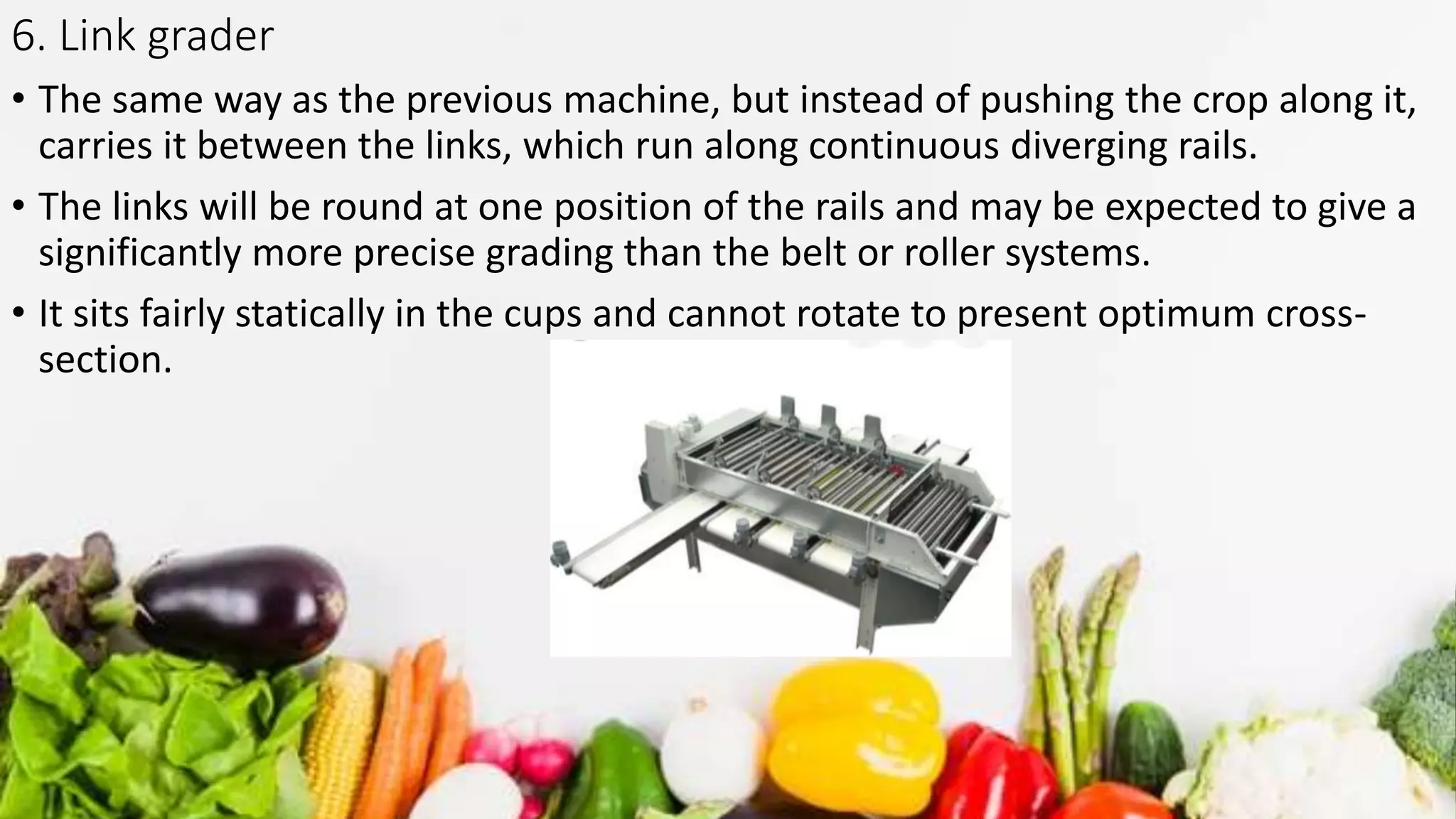

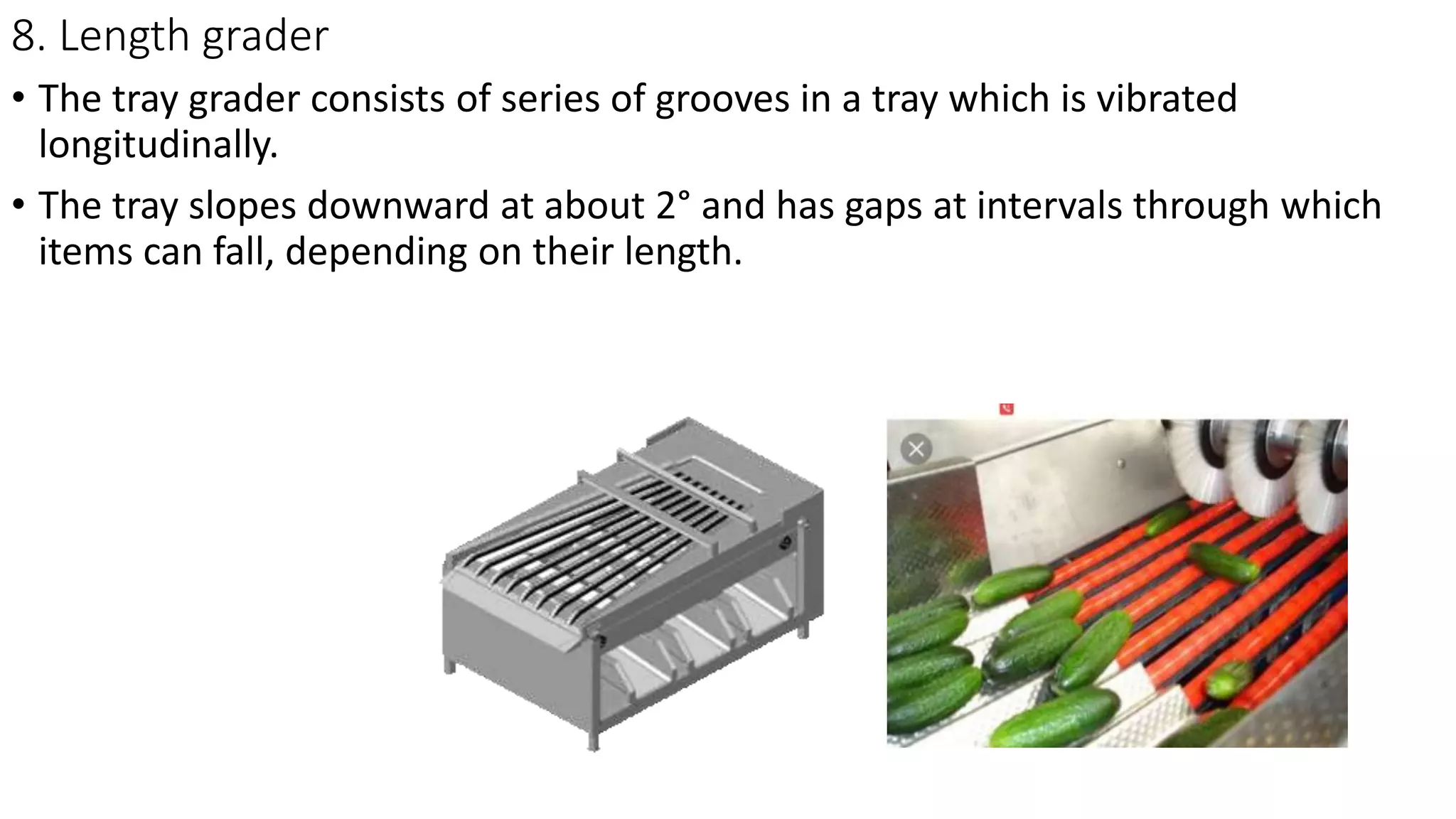

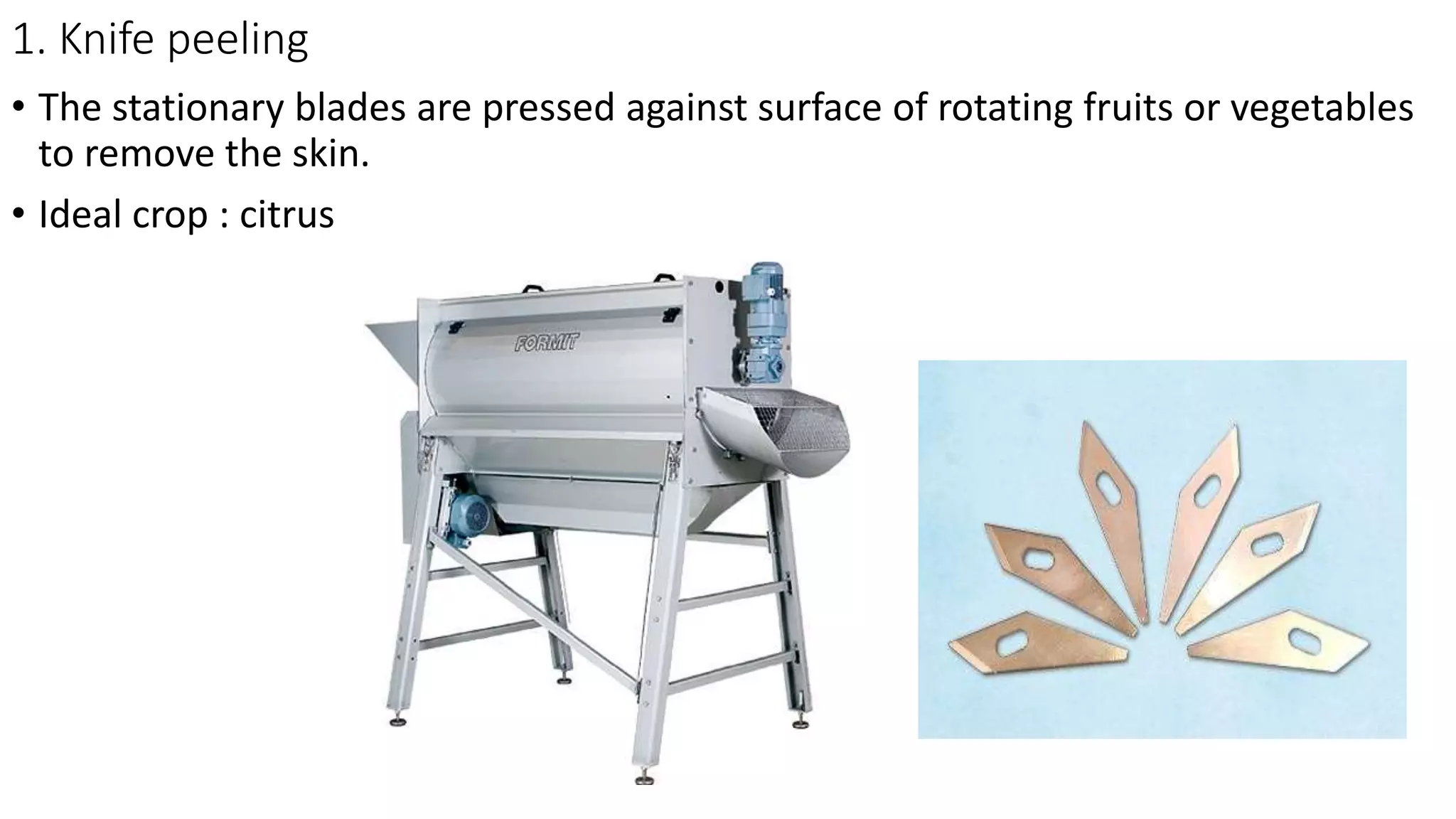

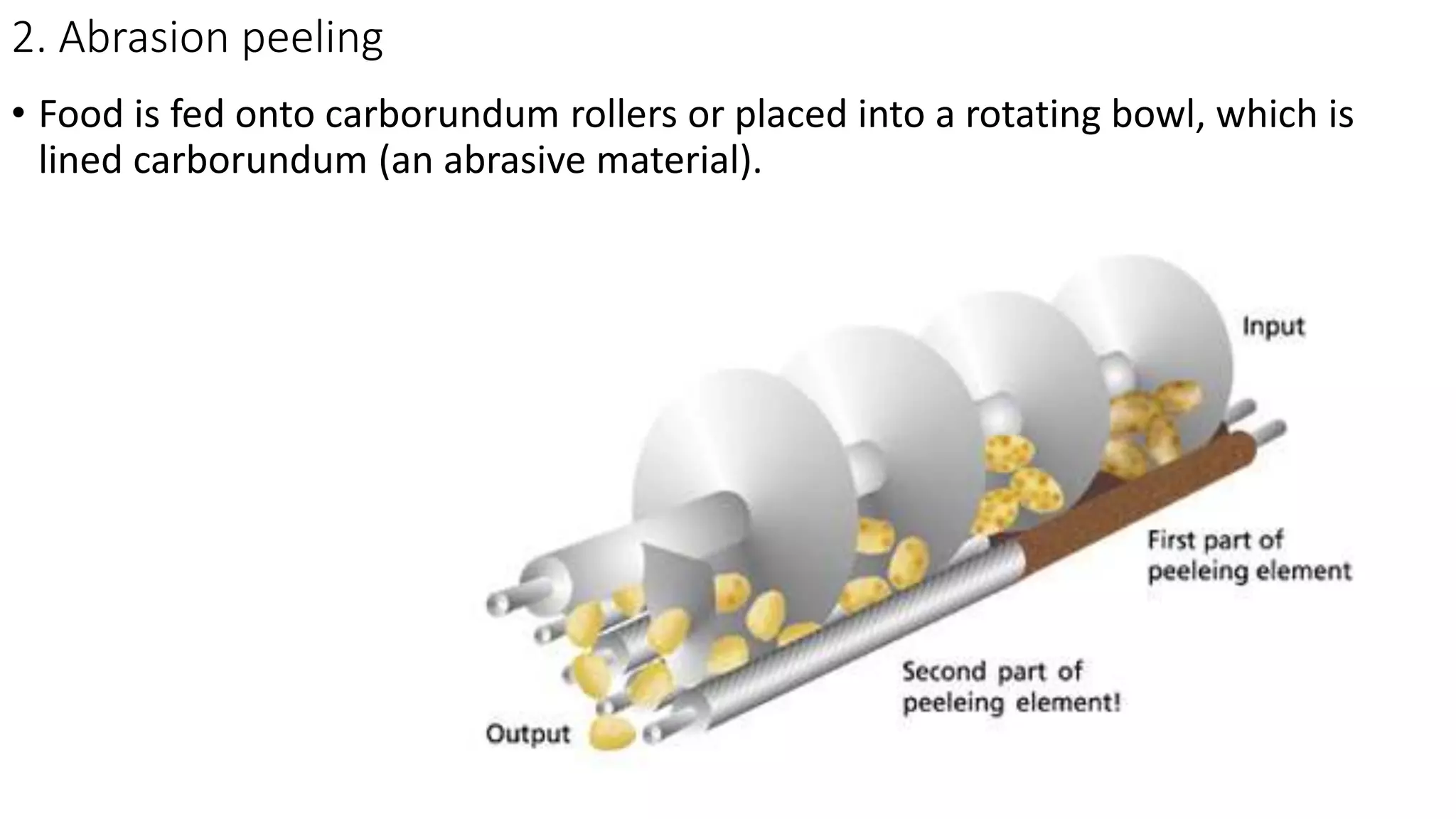

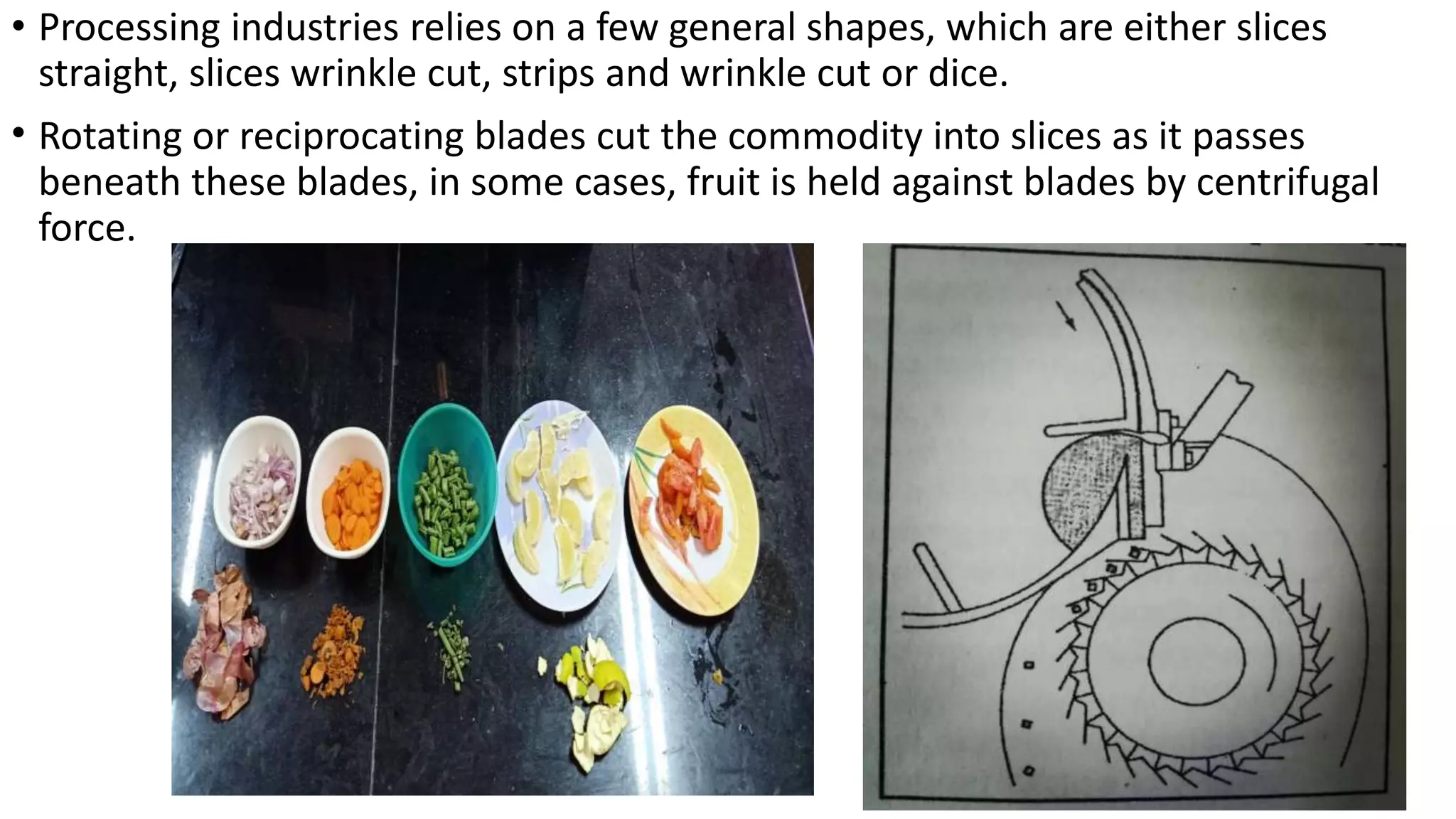

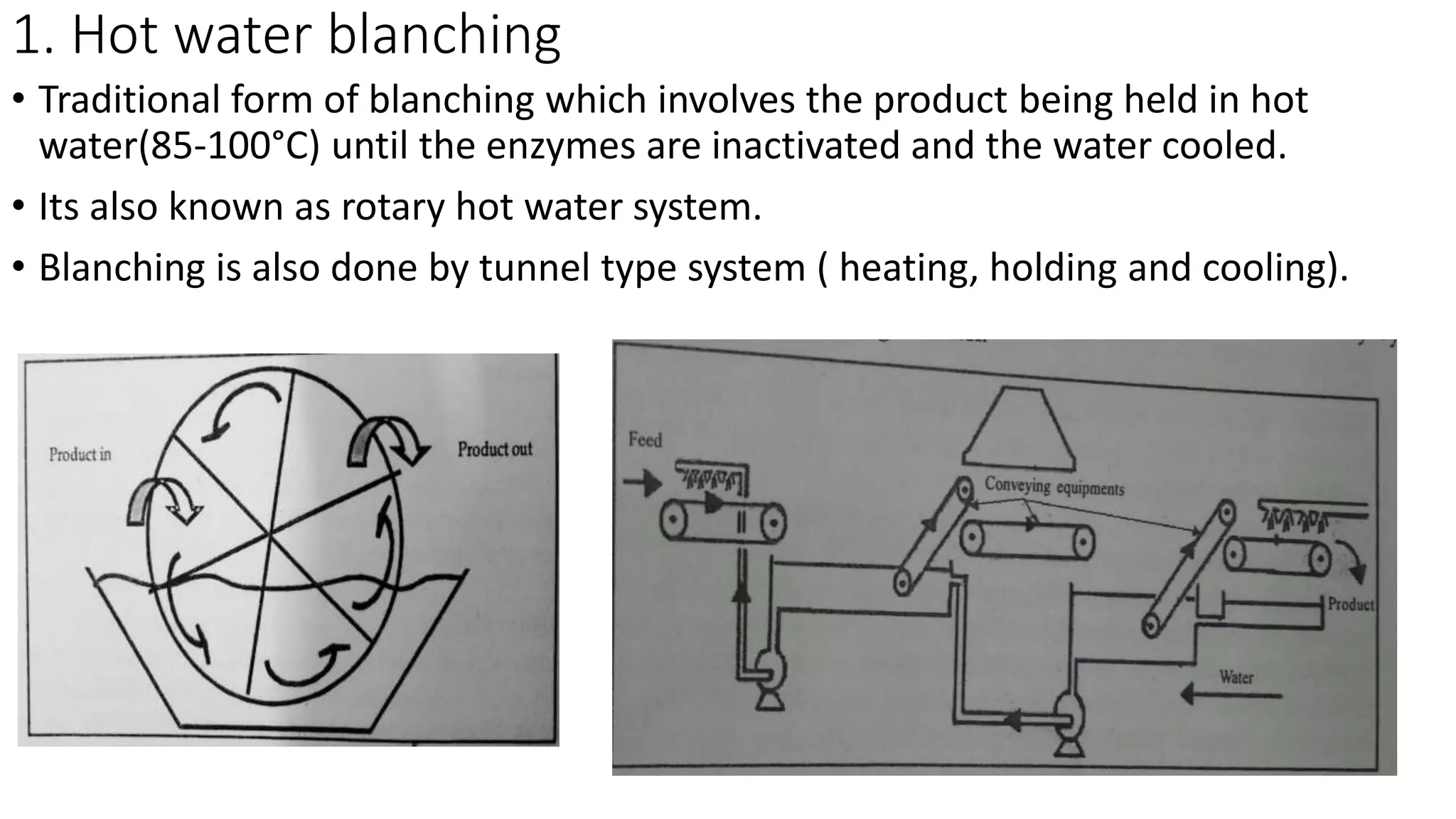

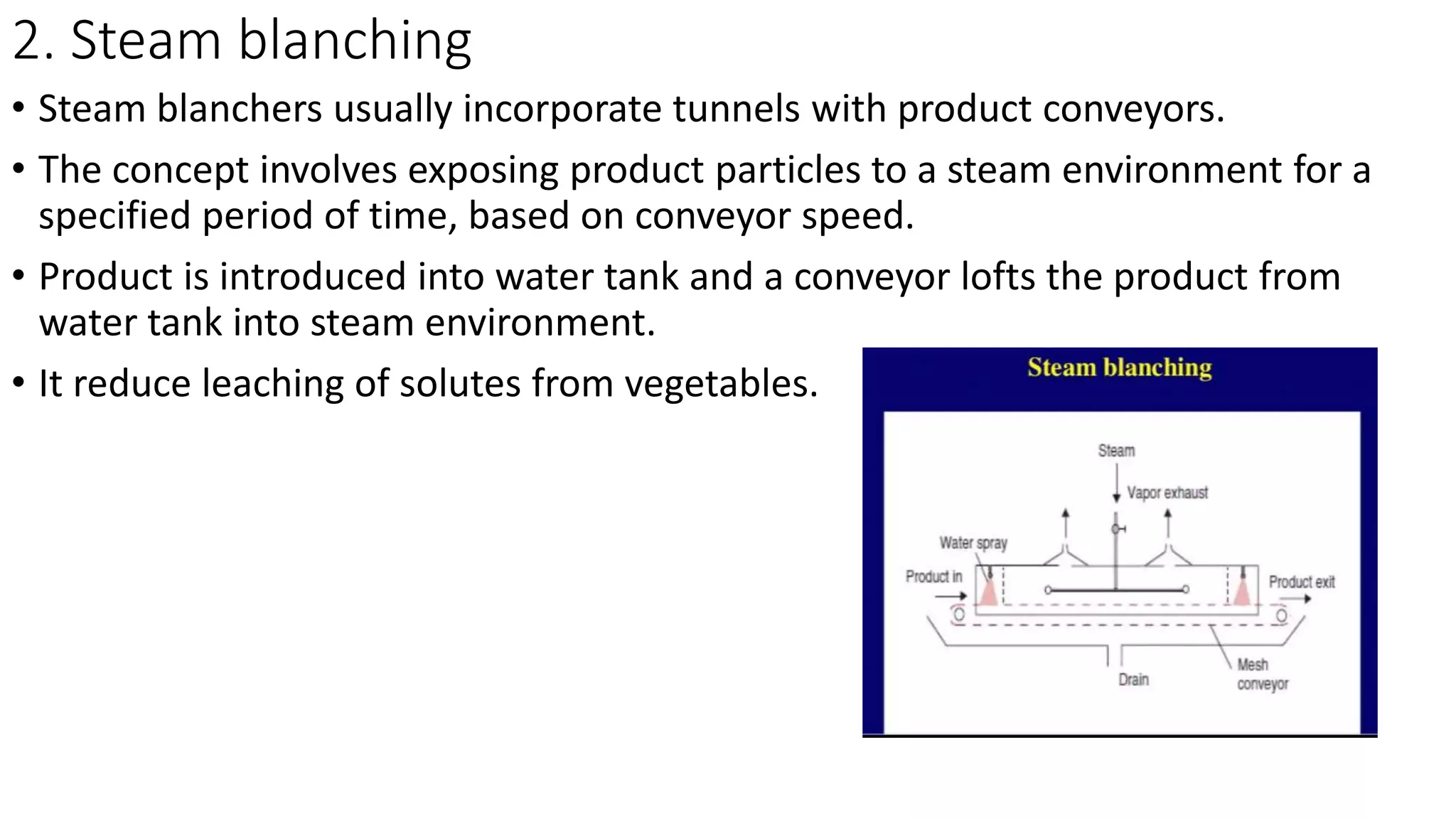

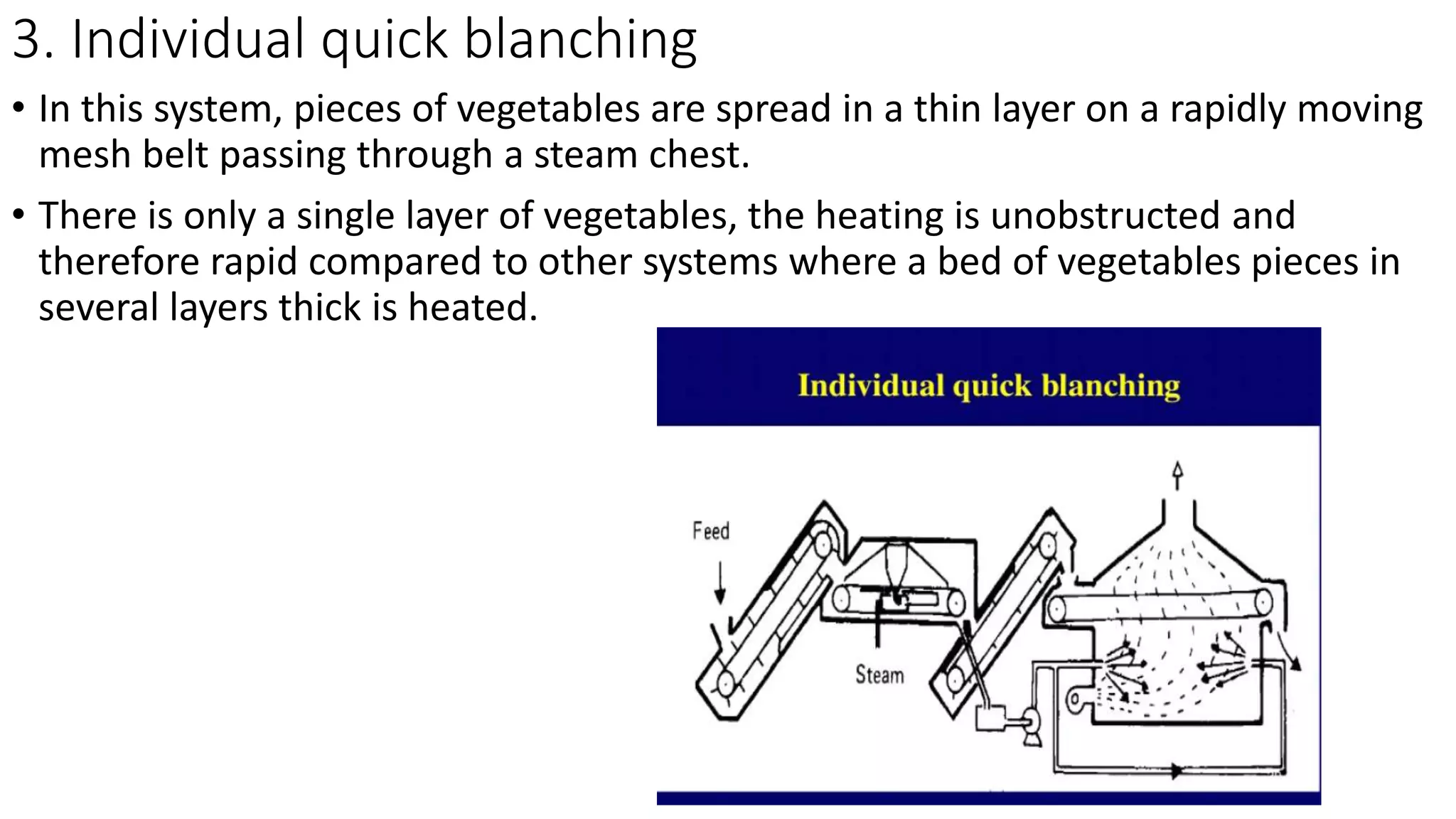

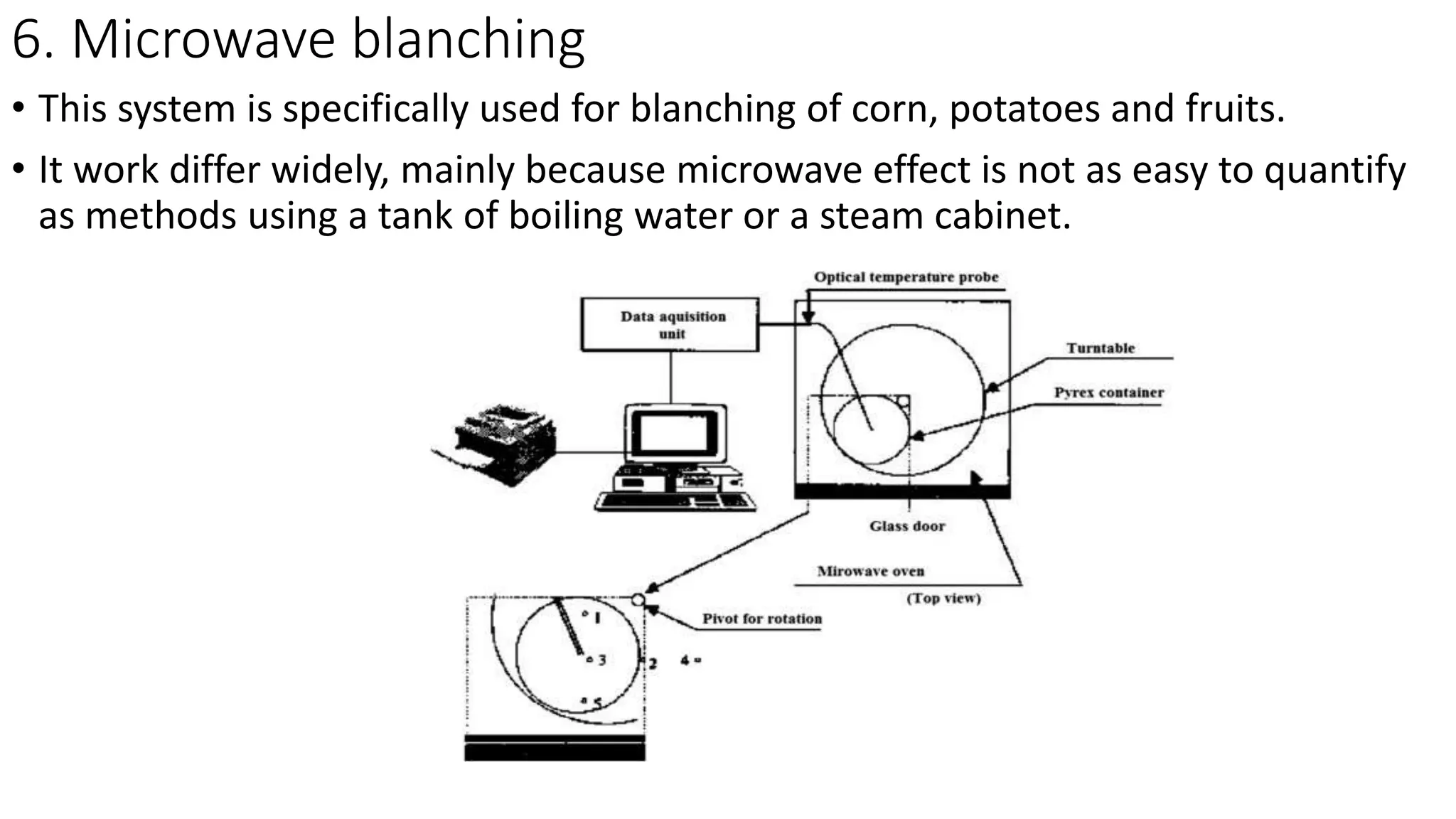

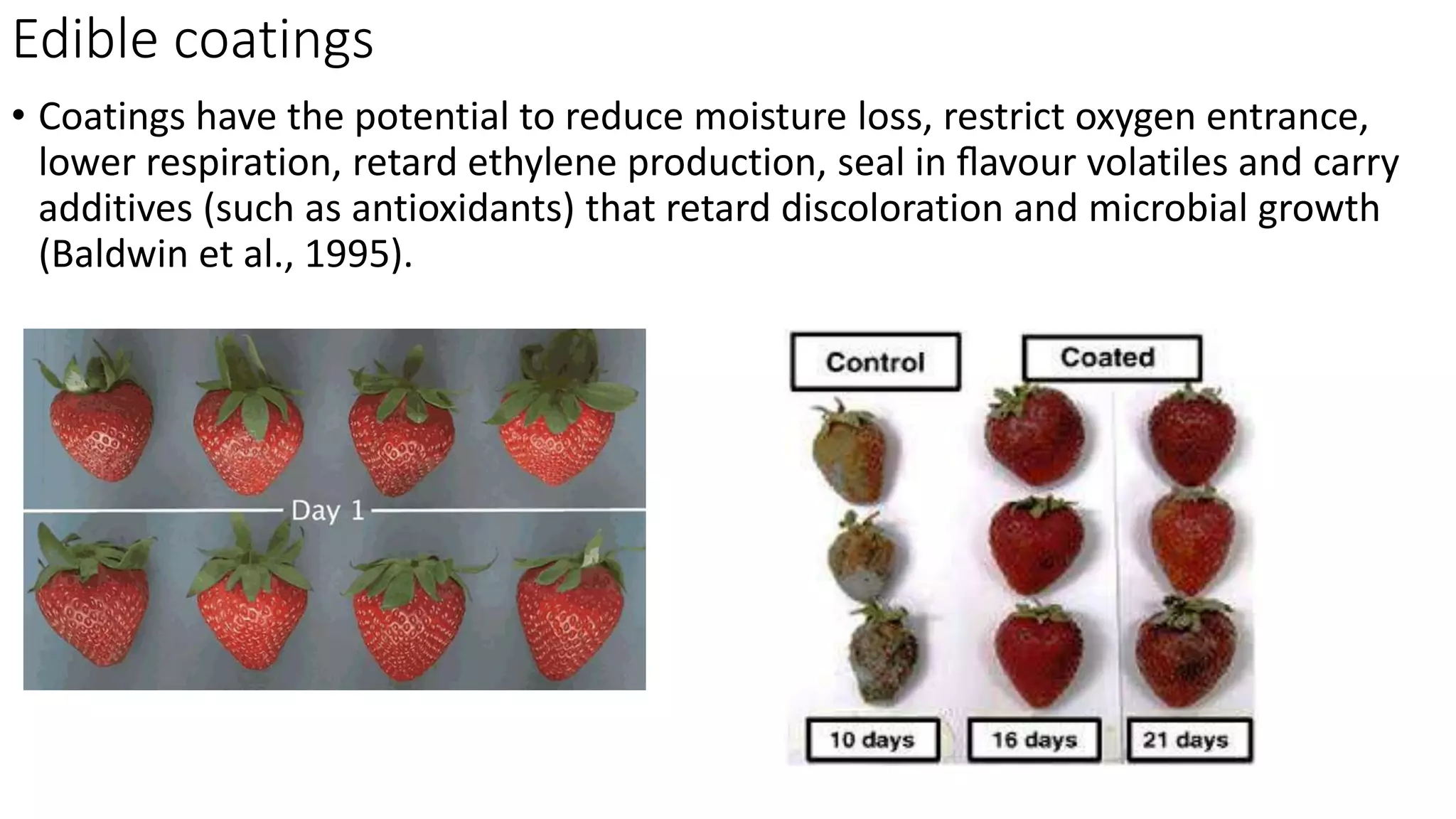

The document discusses primary and minimal processing techniques for fruits and vegetables, including grading, sorting, cleaning, peeling, slicing, and blanching. Various methods and equipment for grading by size and weight, as well as different cleaning techniques are detailed, along with processing methods to extend shelf life and maintain quality. Additionally, it covers packaging solutions and storage conditions to enhance the preservation of processed produce.