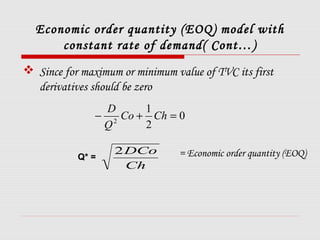

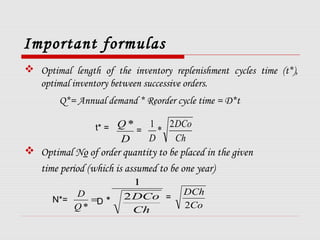

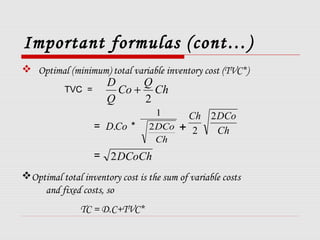

The document discusses inventory control and various inventory models. It describes the components of inventory costs, including purchase costs, order costs, holding costs, and unavailable costs. It then explains the economic order quantity (EOQ) model, which aims to minimize total inventory costs by balancing order and holding costs. The EOQ model and formulas for optimal order quantity, reorder cycle time, number of orders, and total costs are provided. Extensions of the EOQ model for quantity discounts and warehouse space constraints are also summarized.