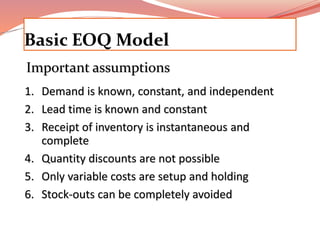

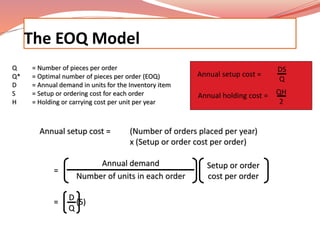

The document discusses inventory management concepts including the reasons for holding inventory, types of inventory, costs of inventory, and inventory control systems. It describes the economic order quantity (EOQ) model which aims to minimize total inventory costs by balancing ordering and holding costs. The EOQ model assumes constant demand, lead times, and avoids stockouts. ABC analysis prioritizes inventory items based on their value to focus management efforts on the most important items. Cycle counting helps maintain accurate inventory records by regularly counting samples of inventory.