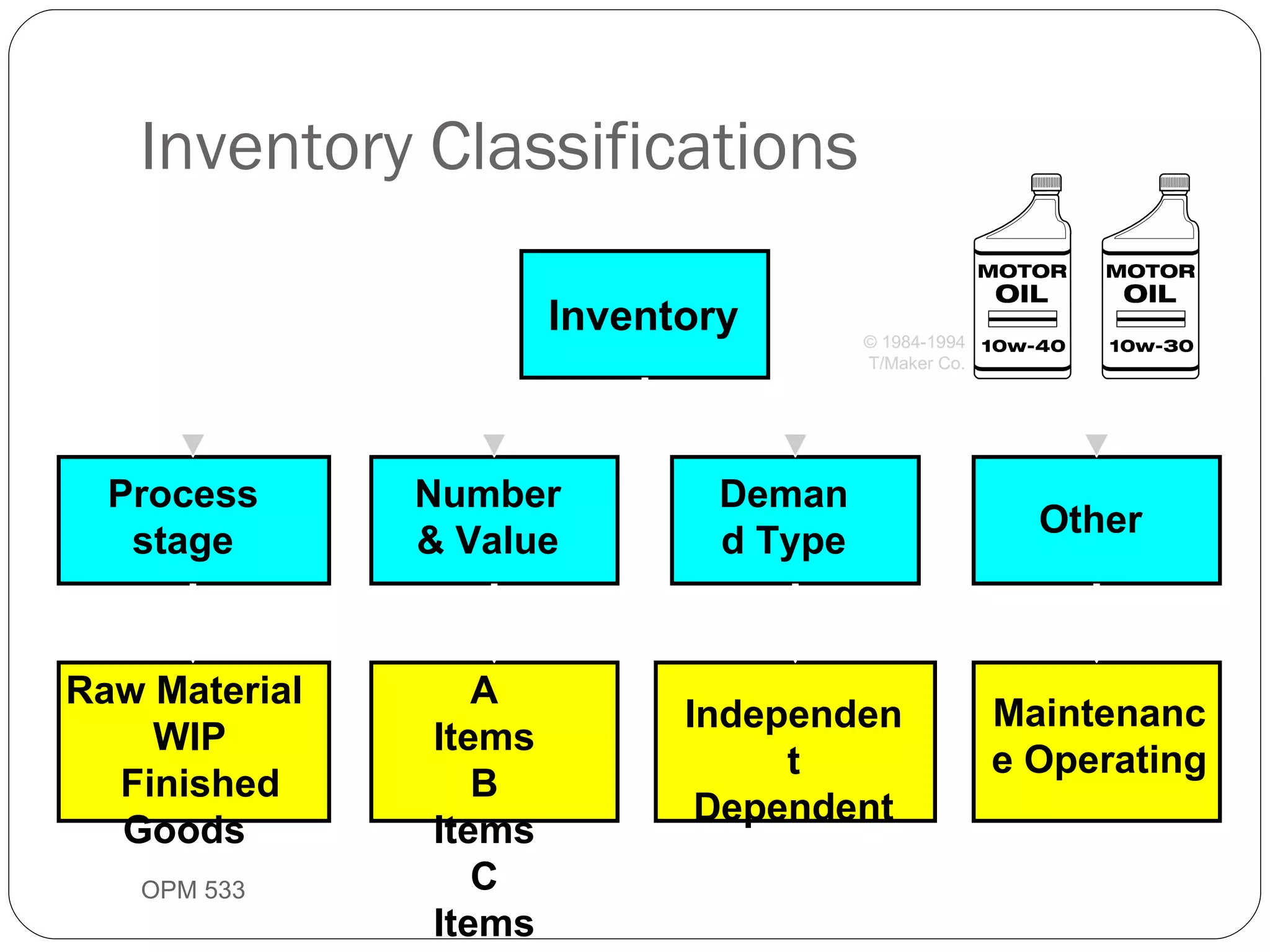

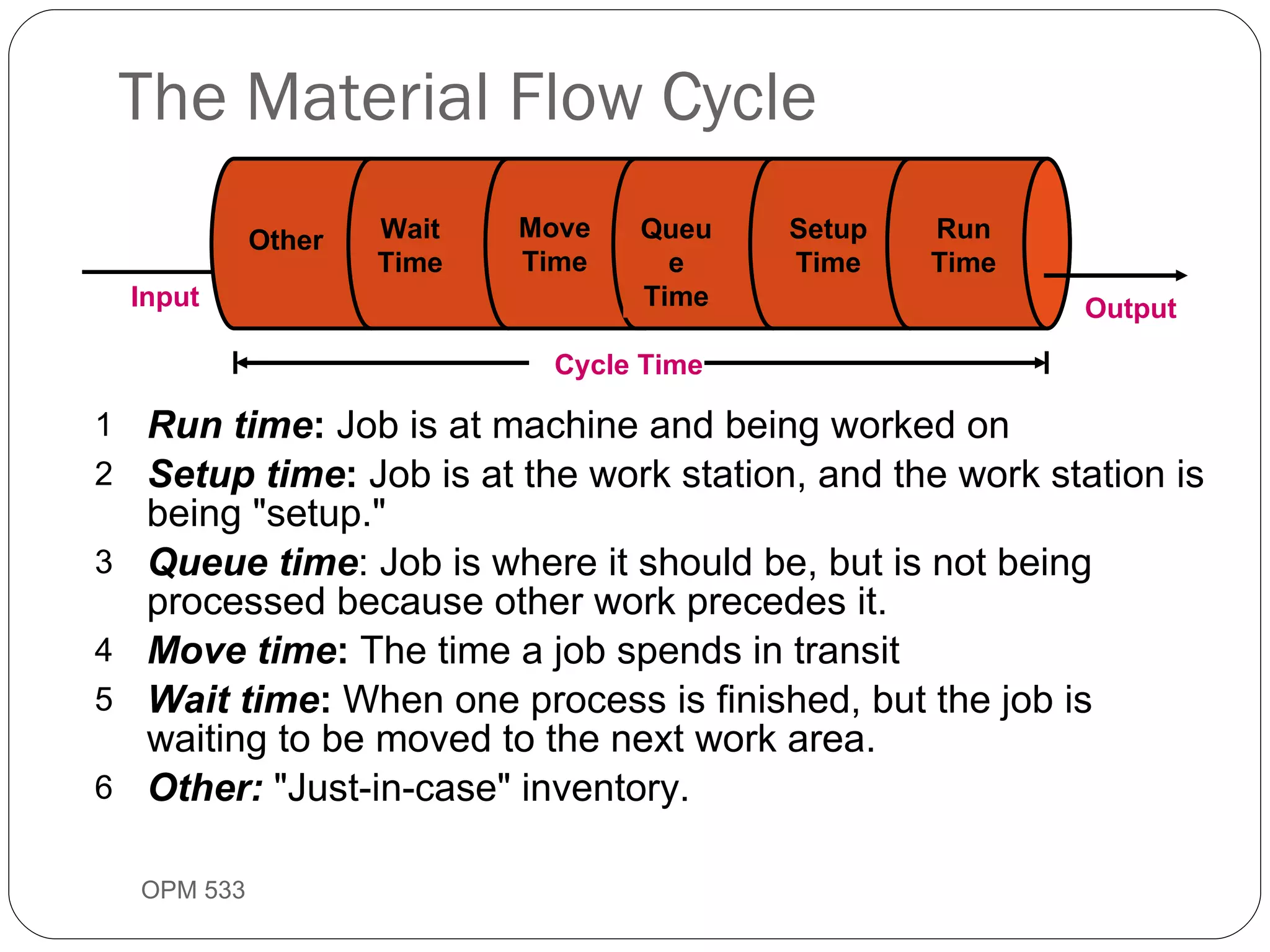

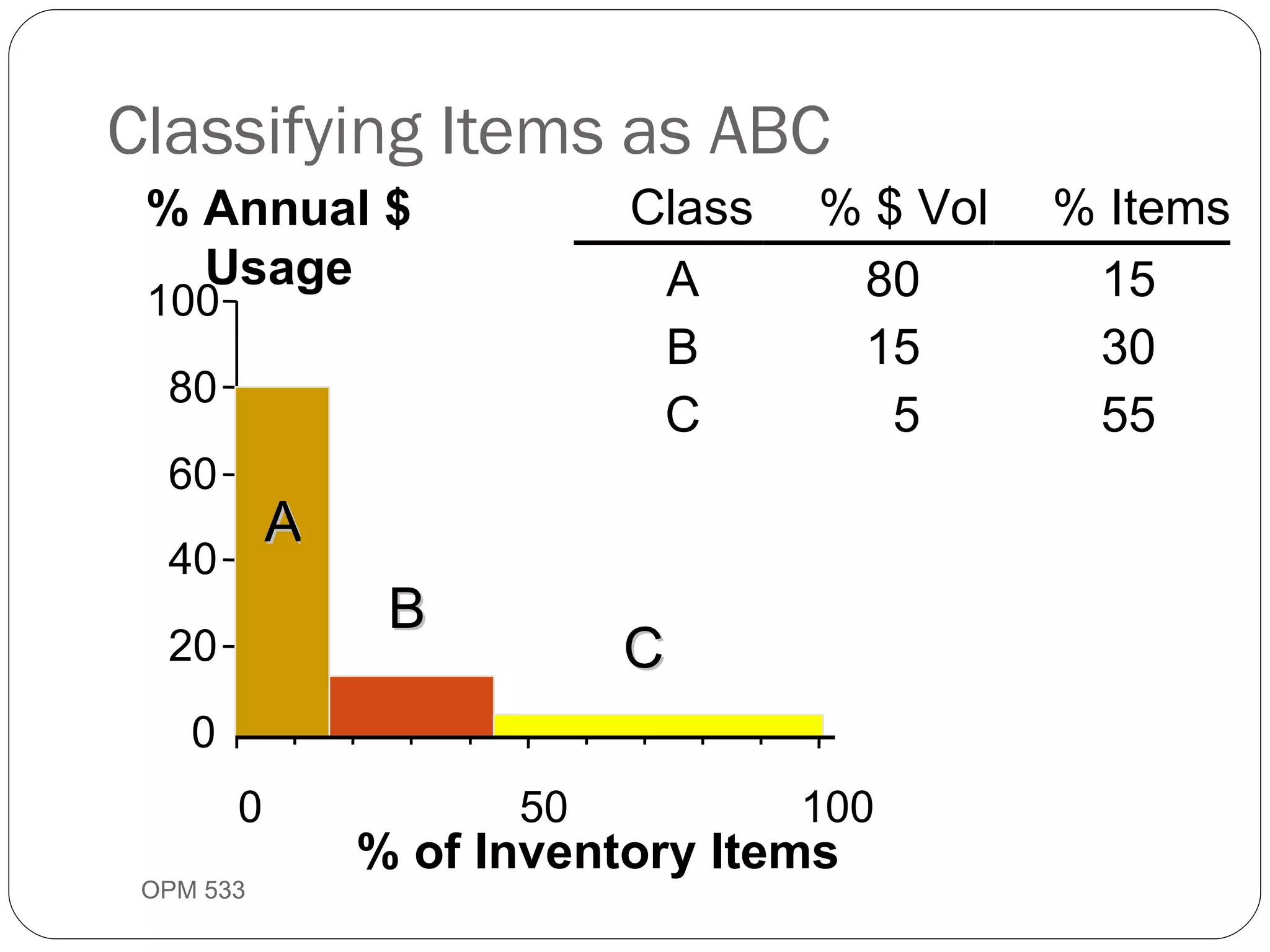

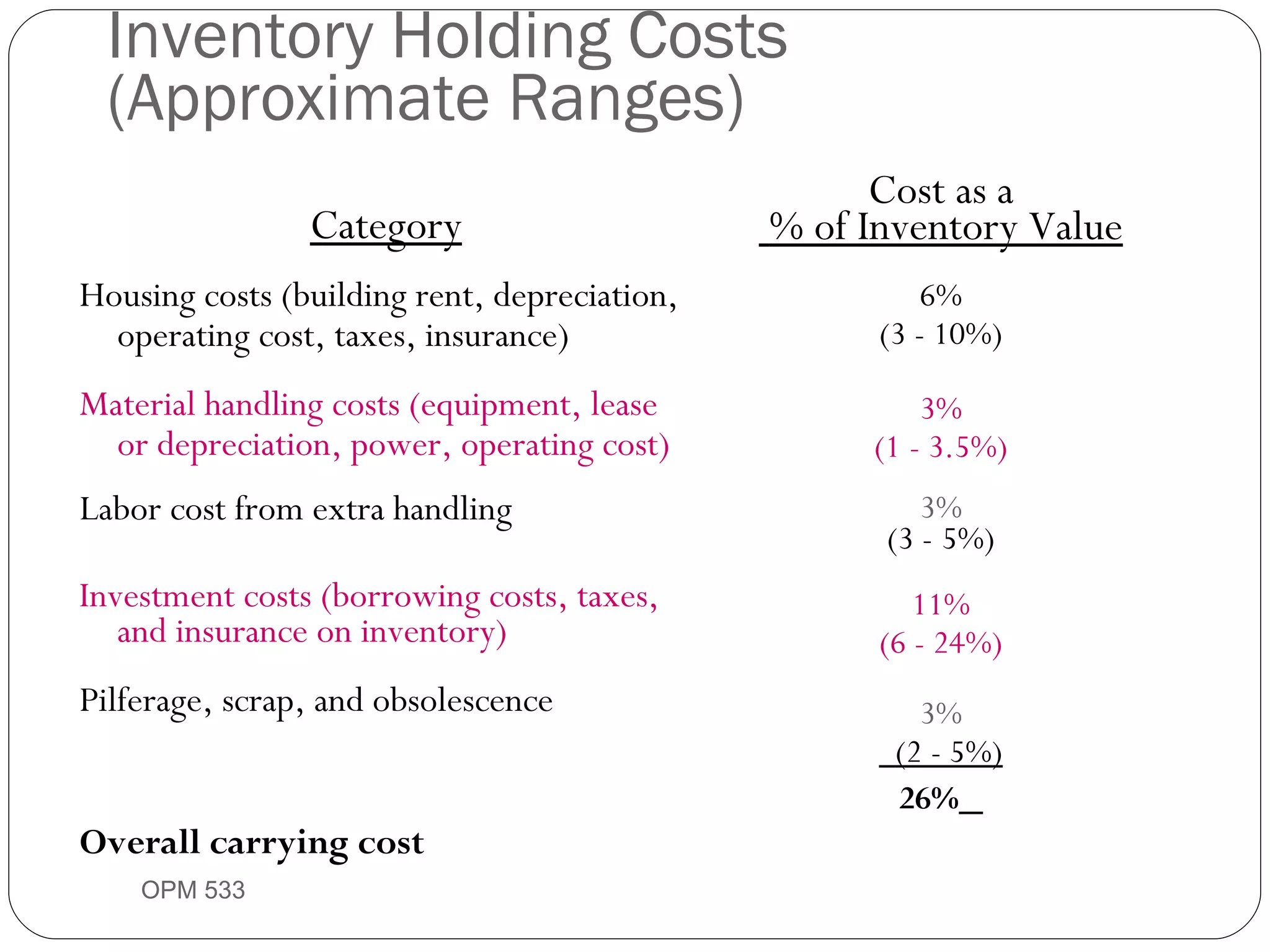

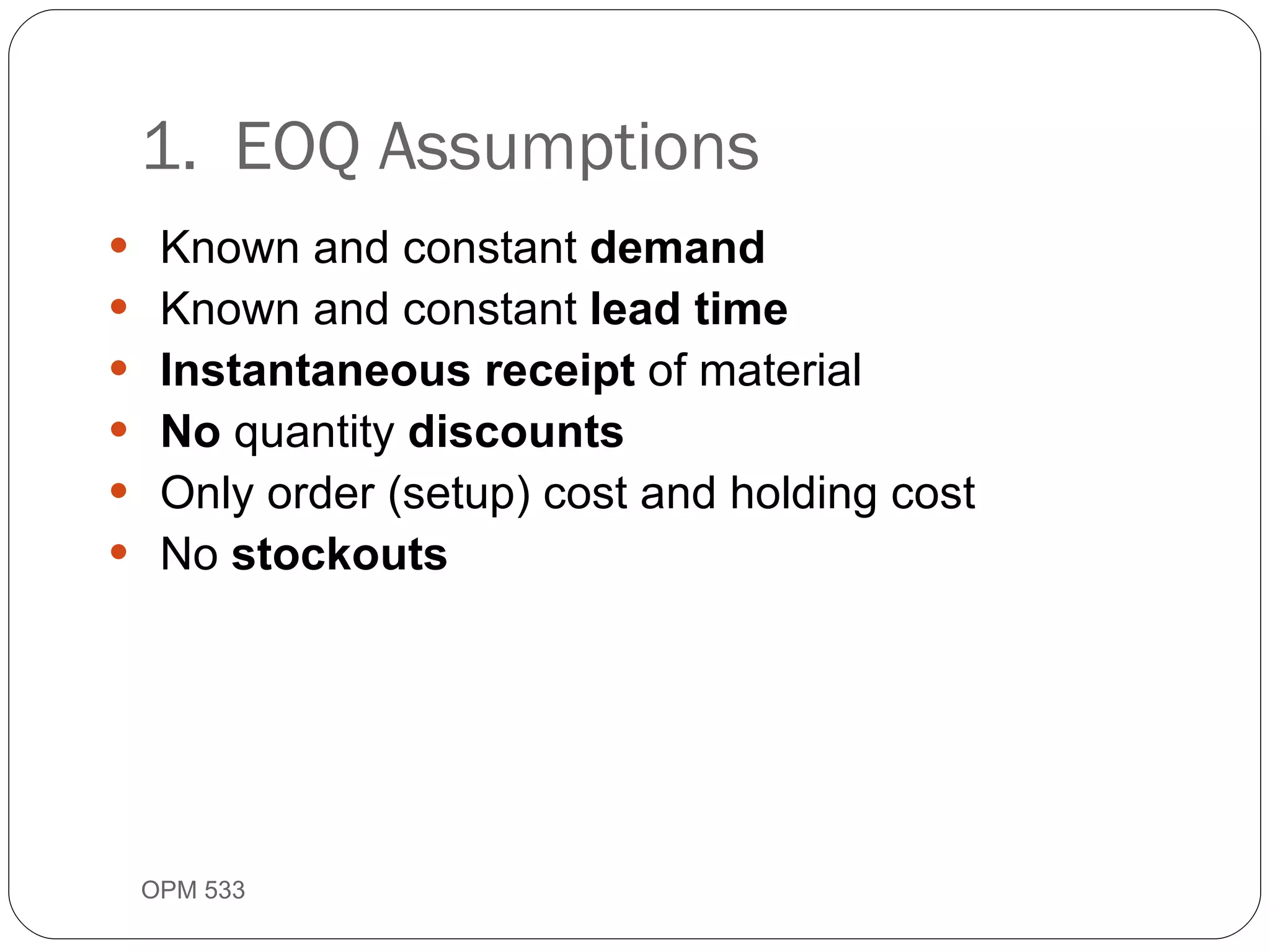

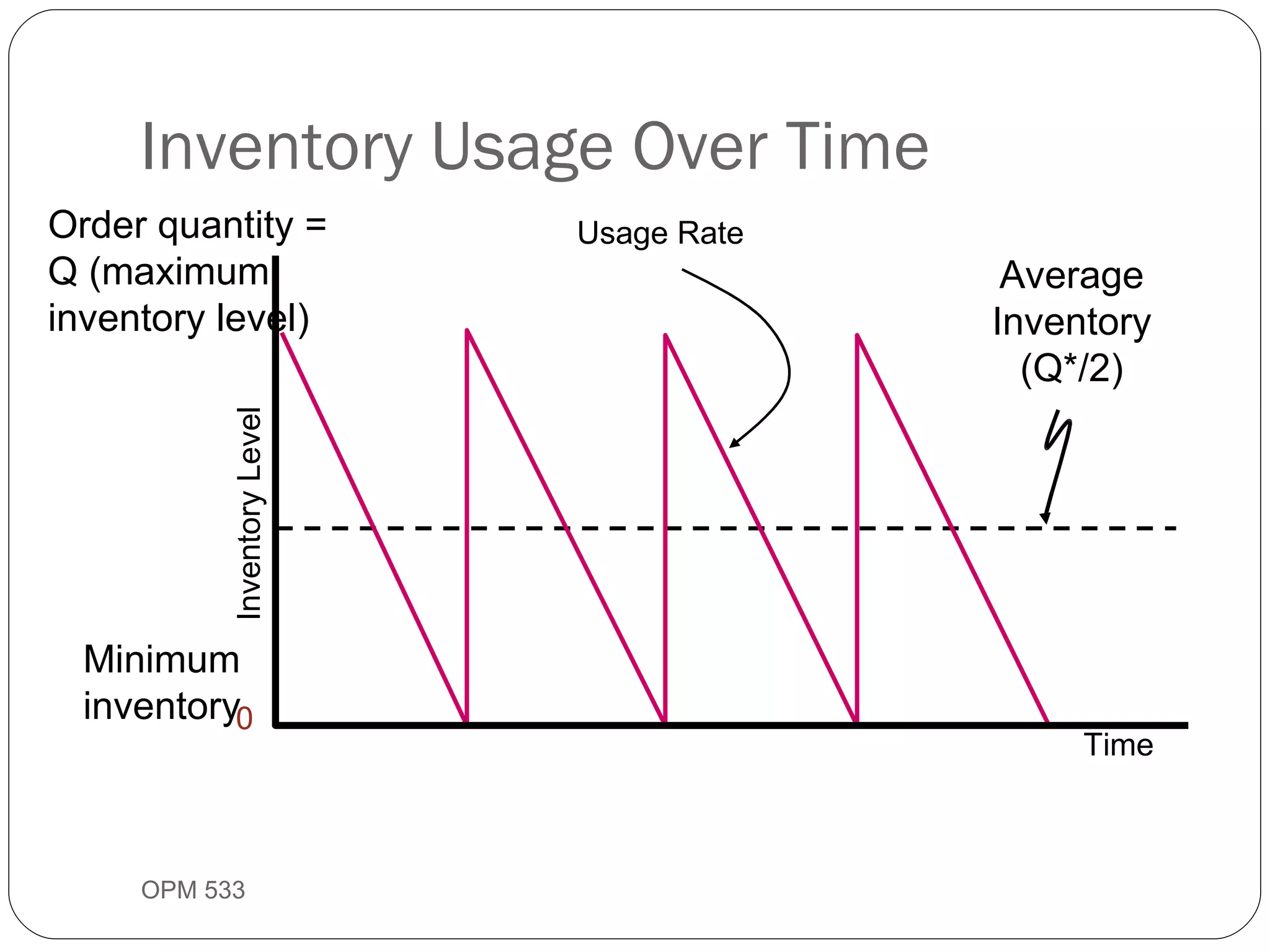

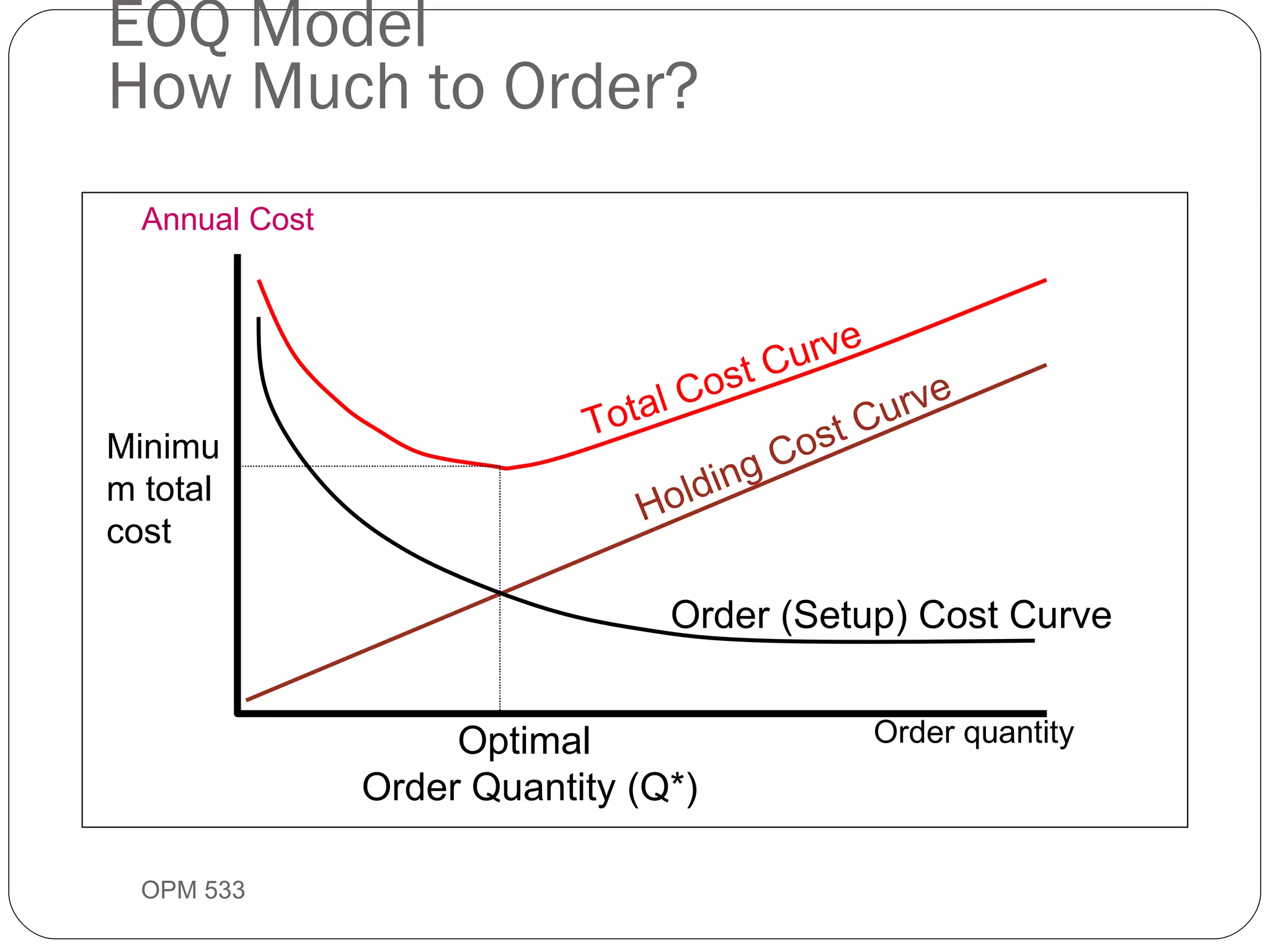

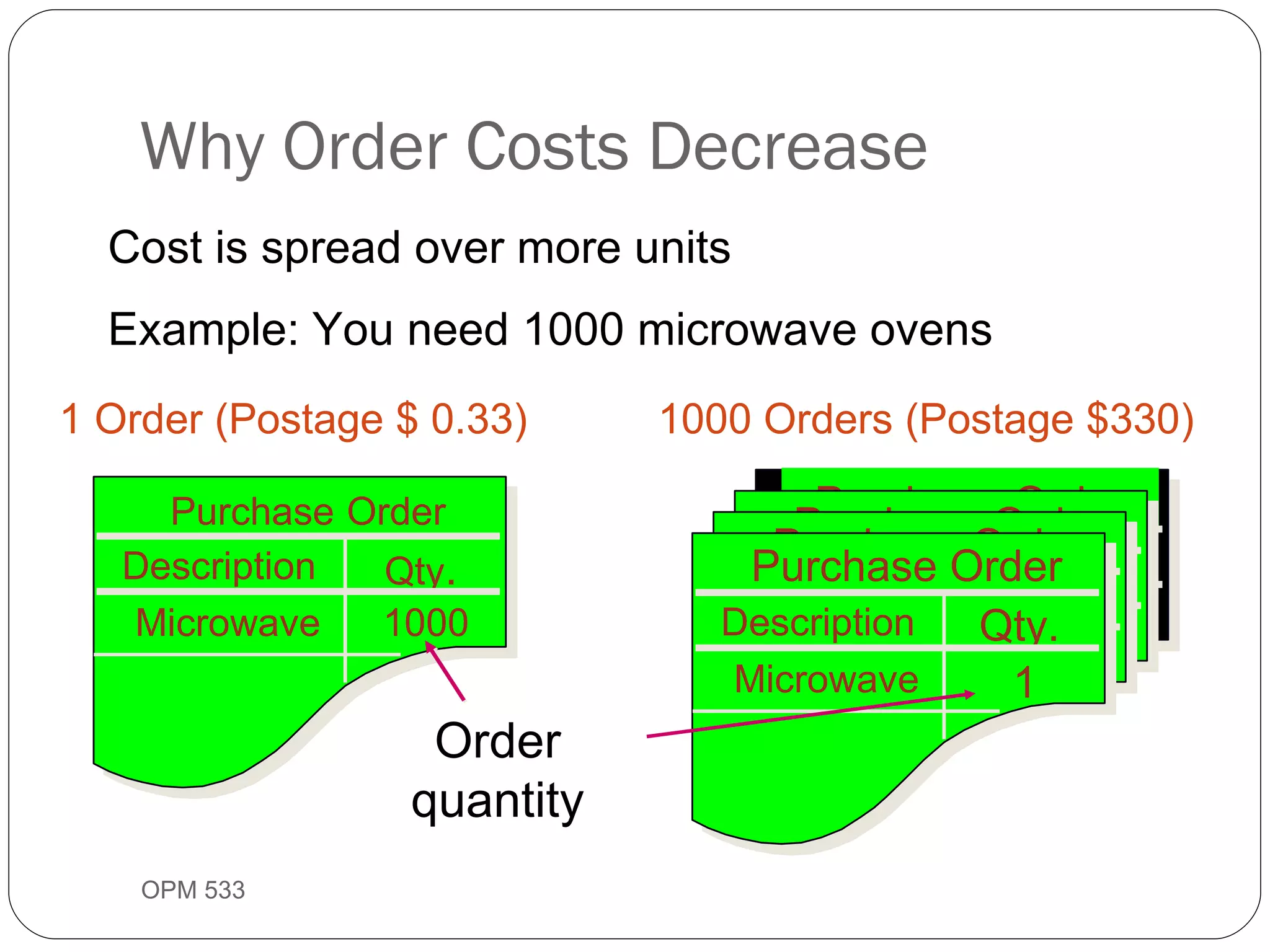

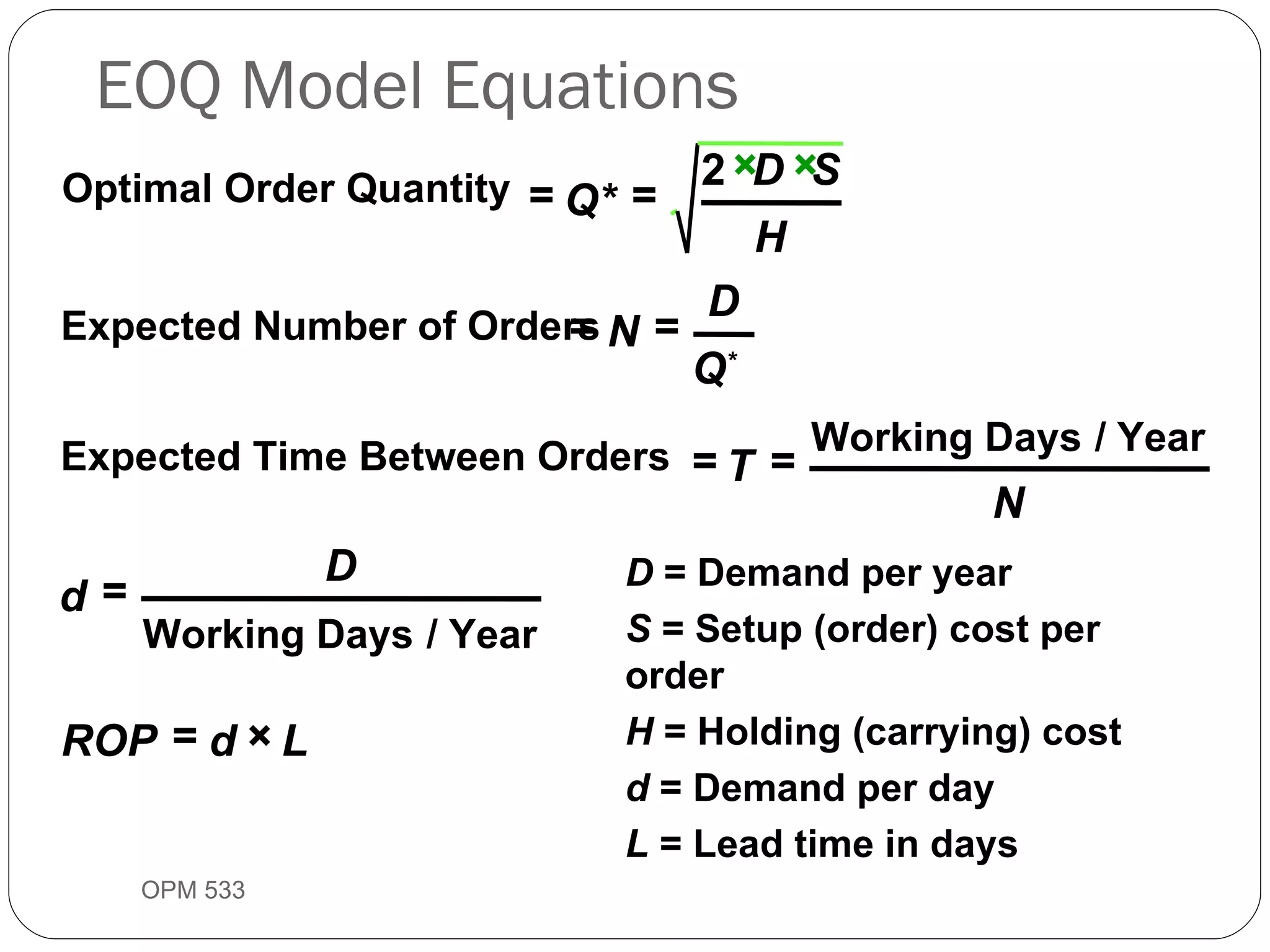

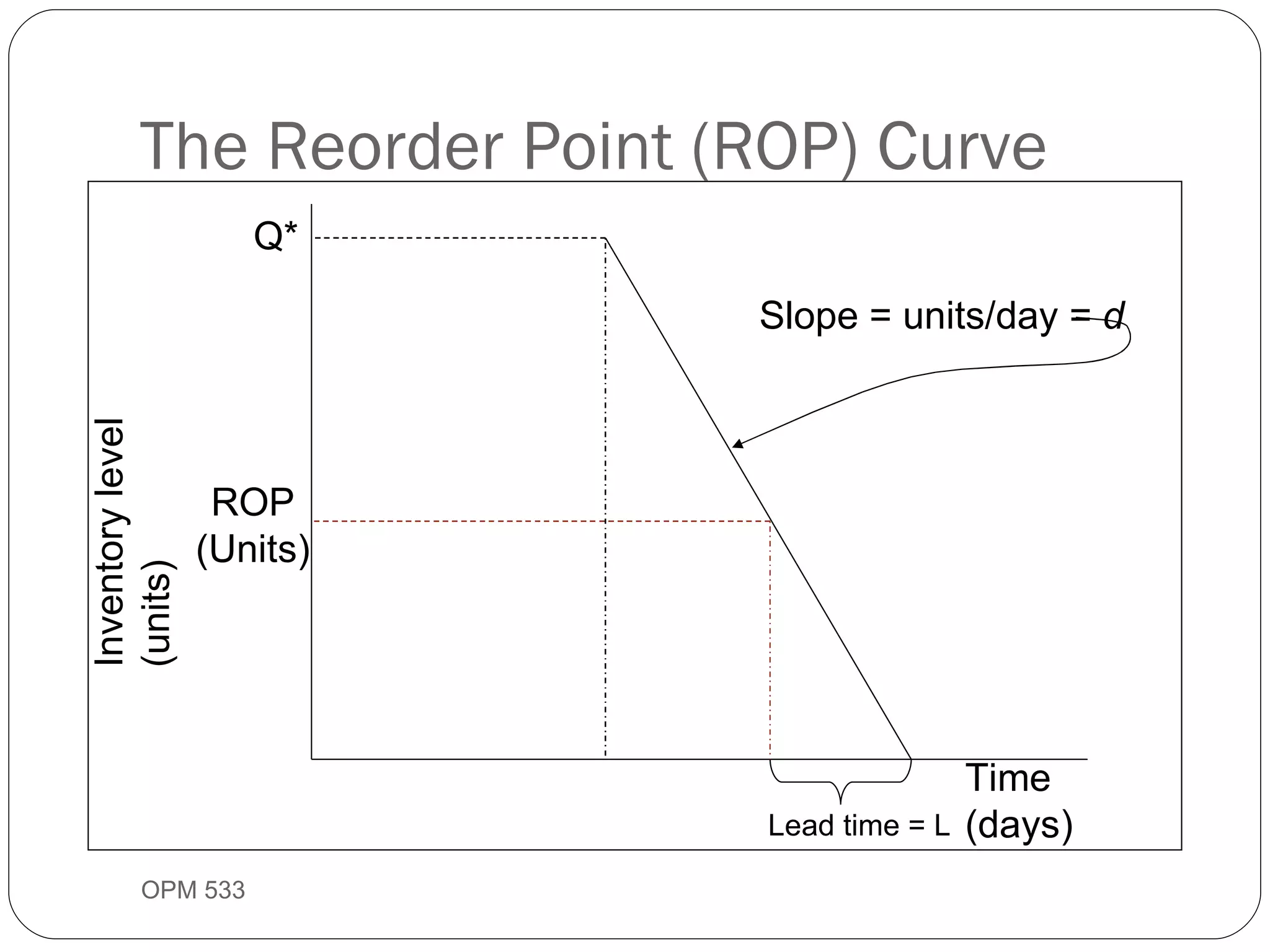

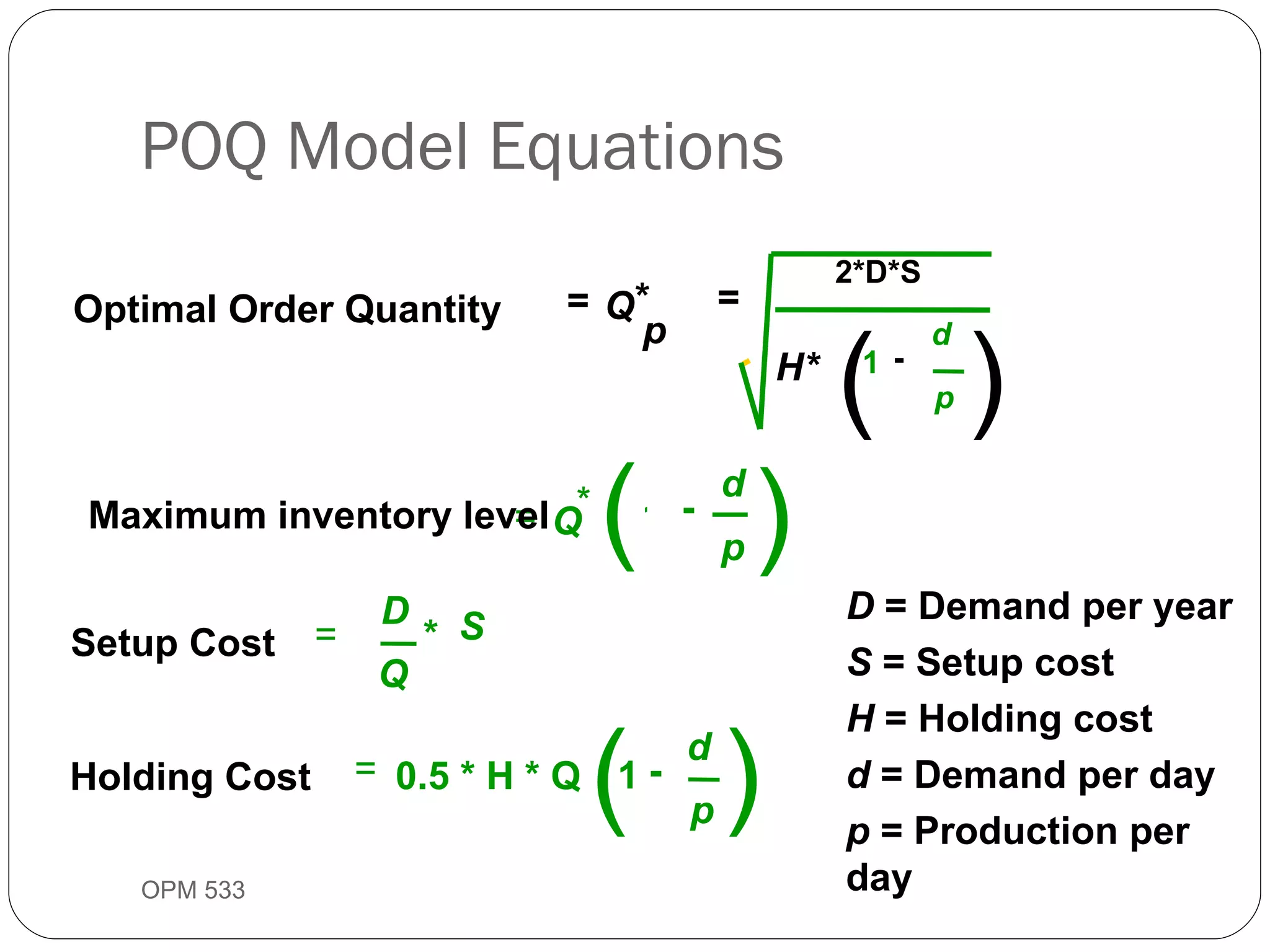

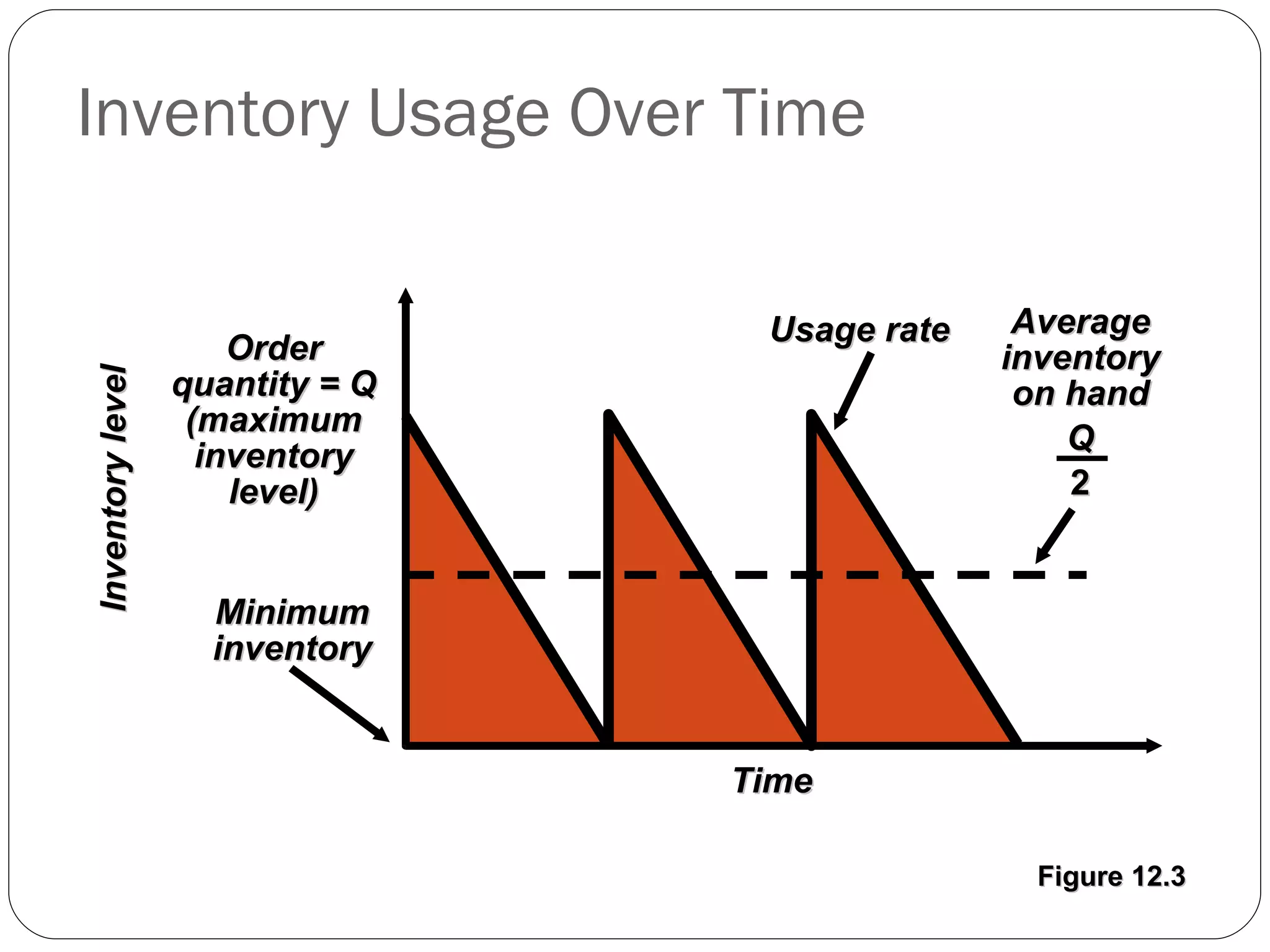

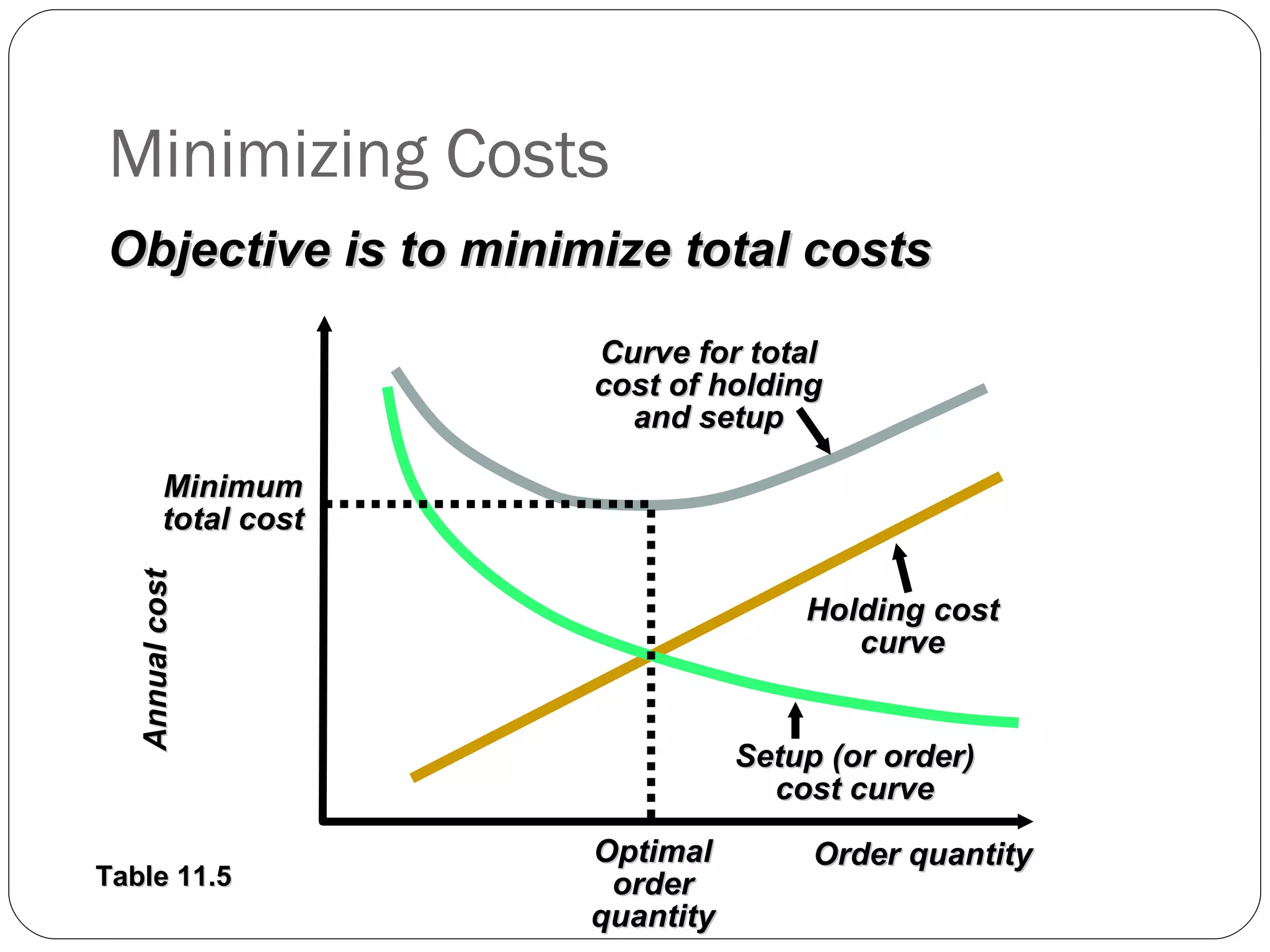

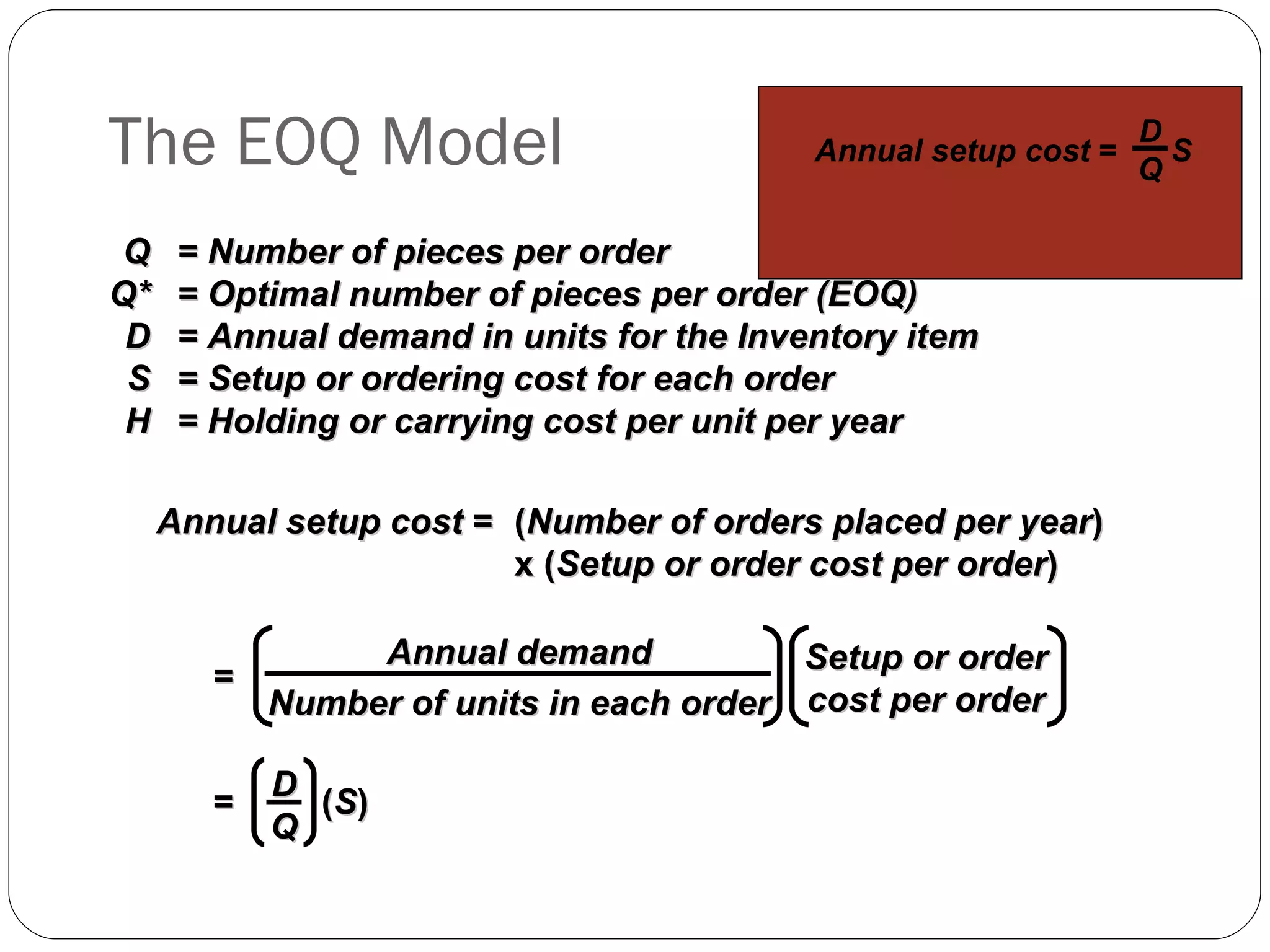

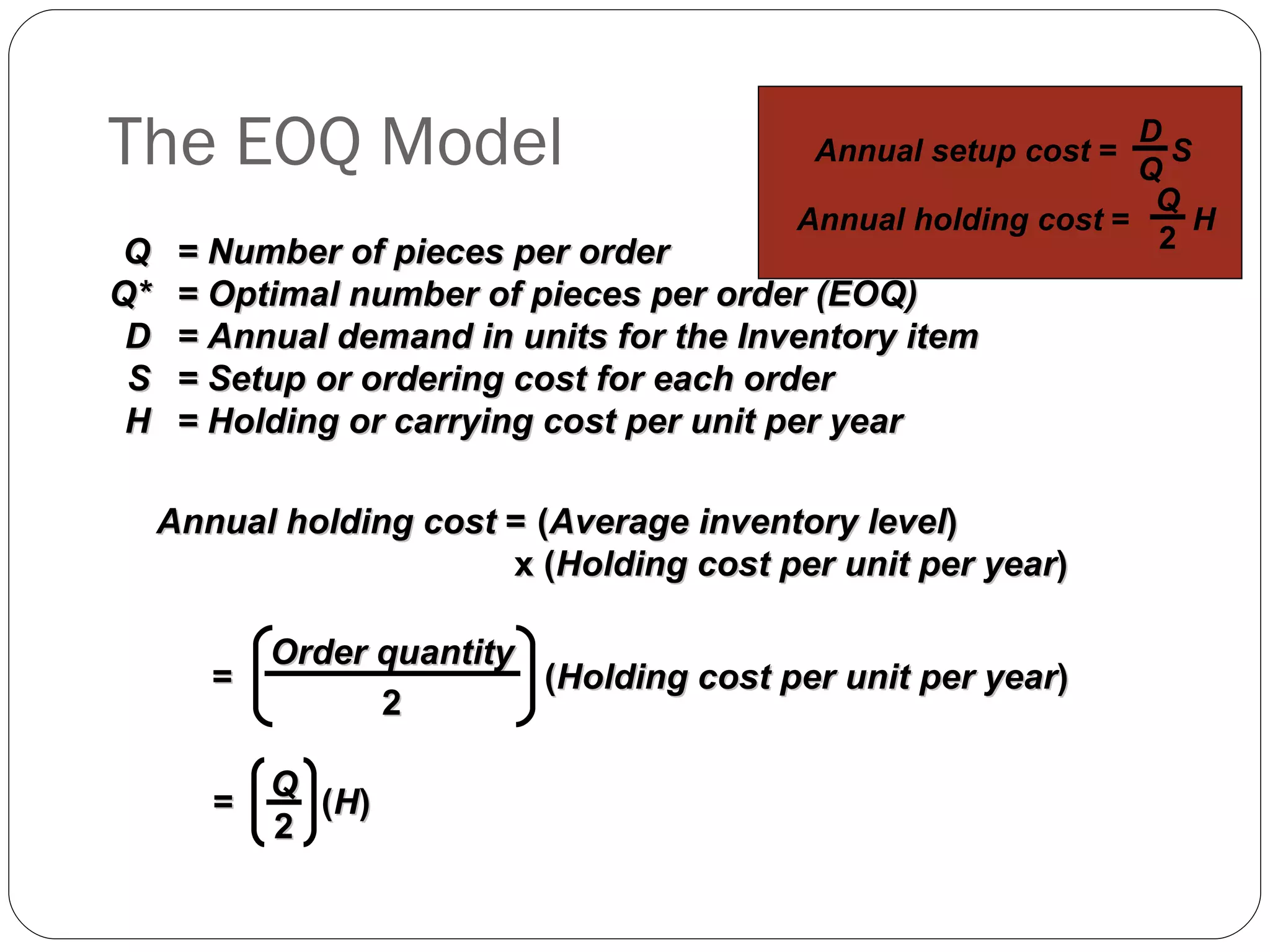

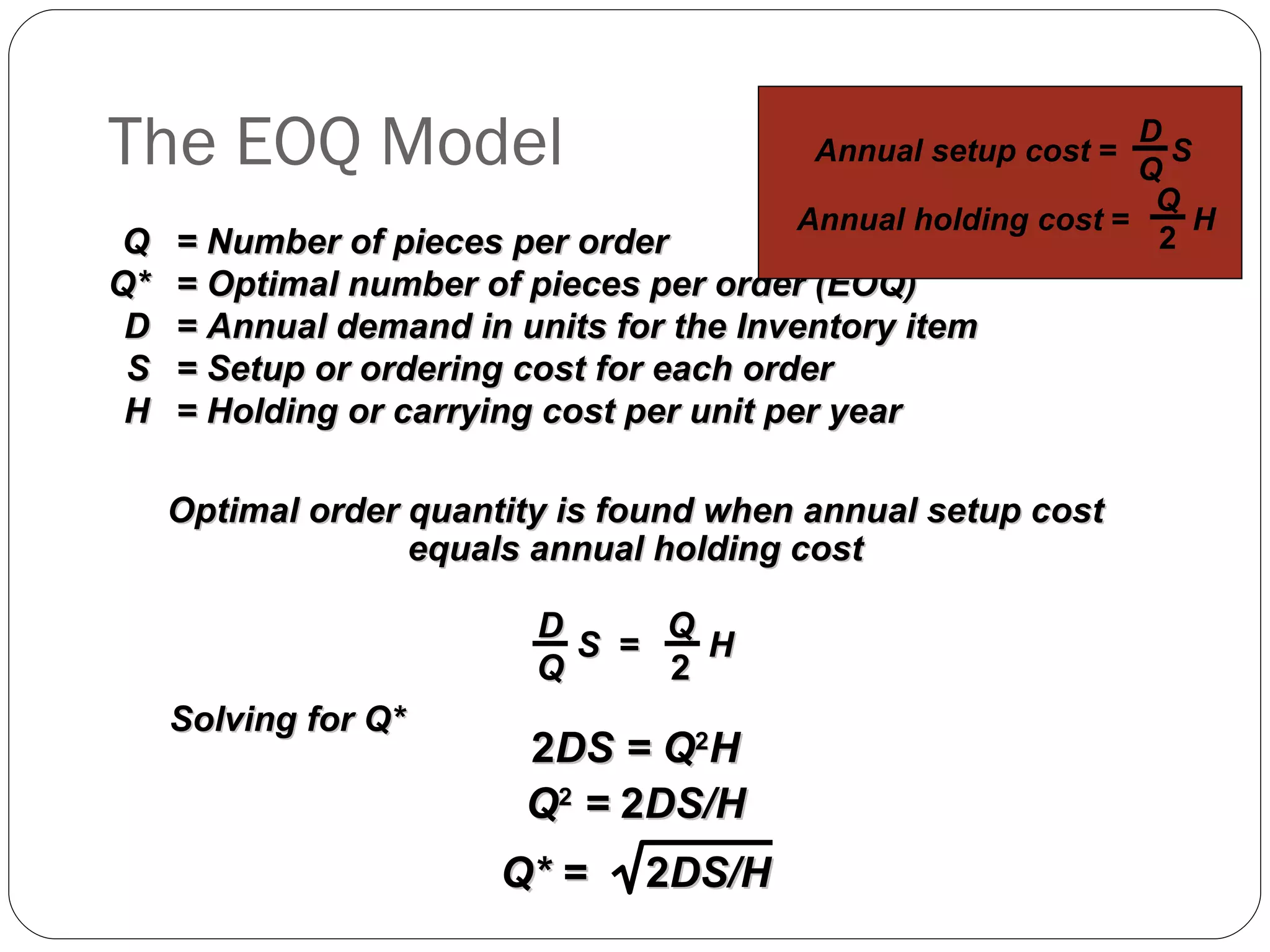

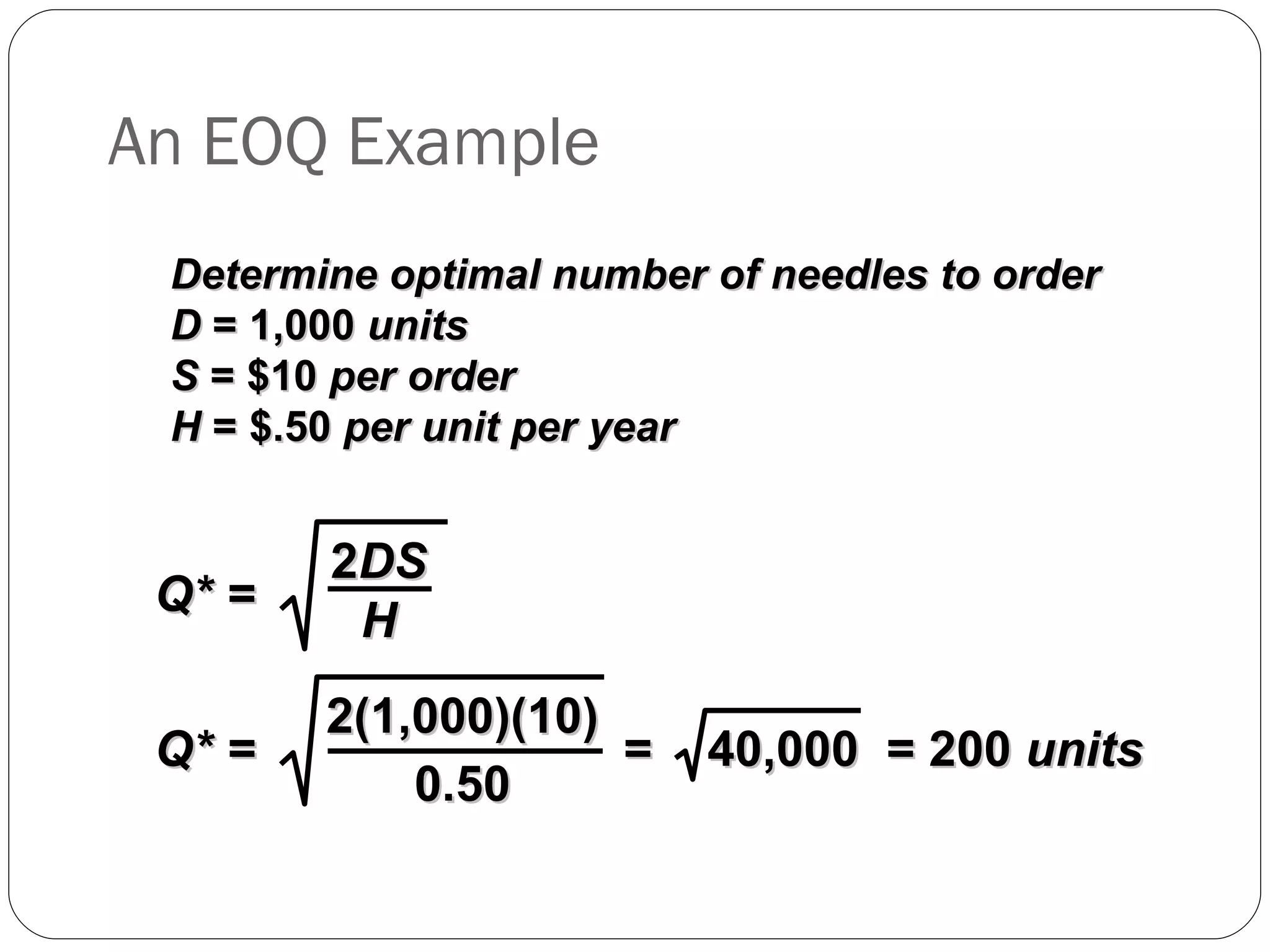

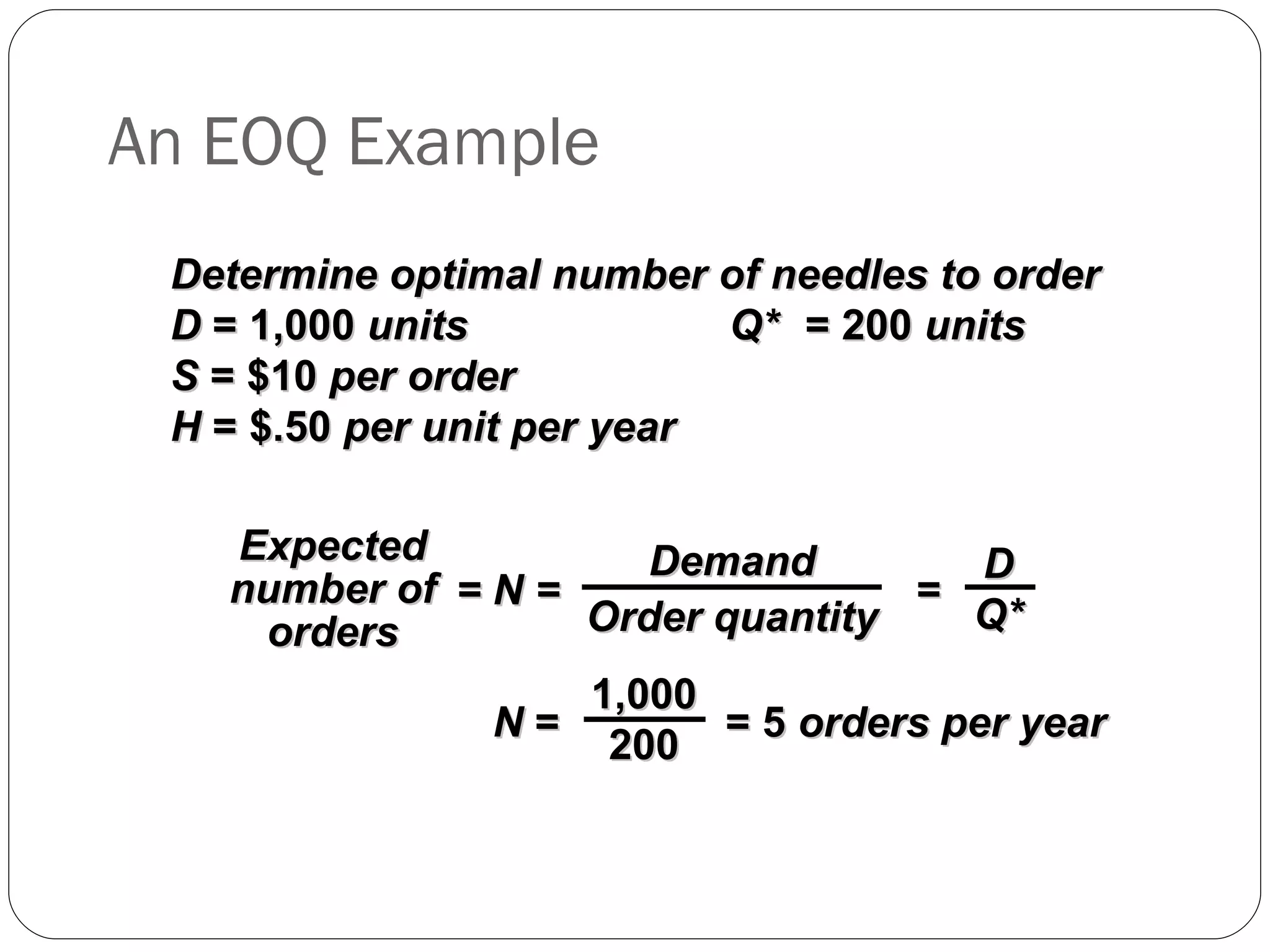

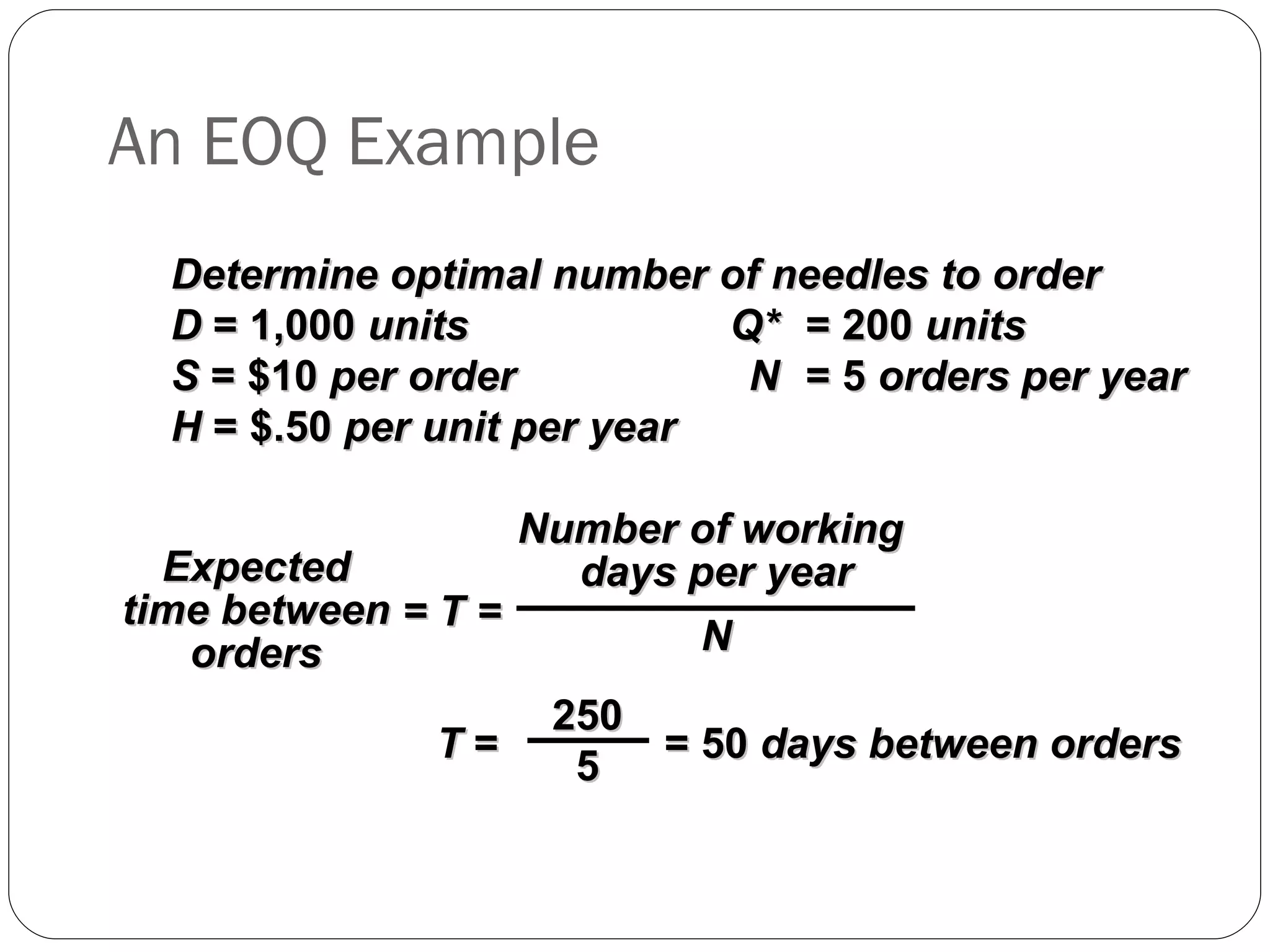

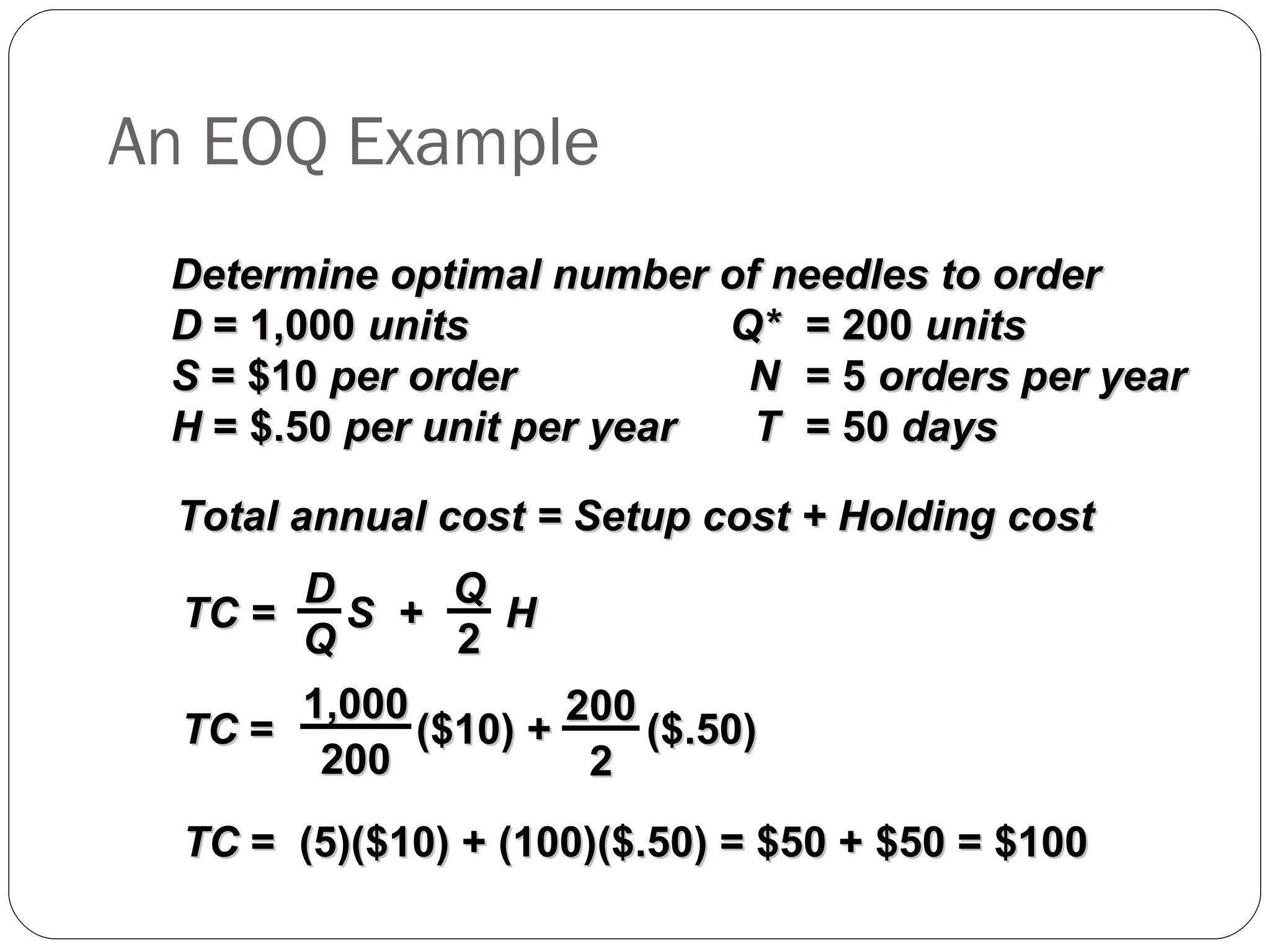

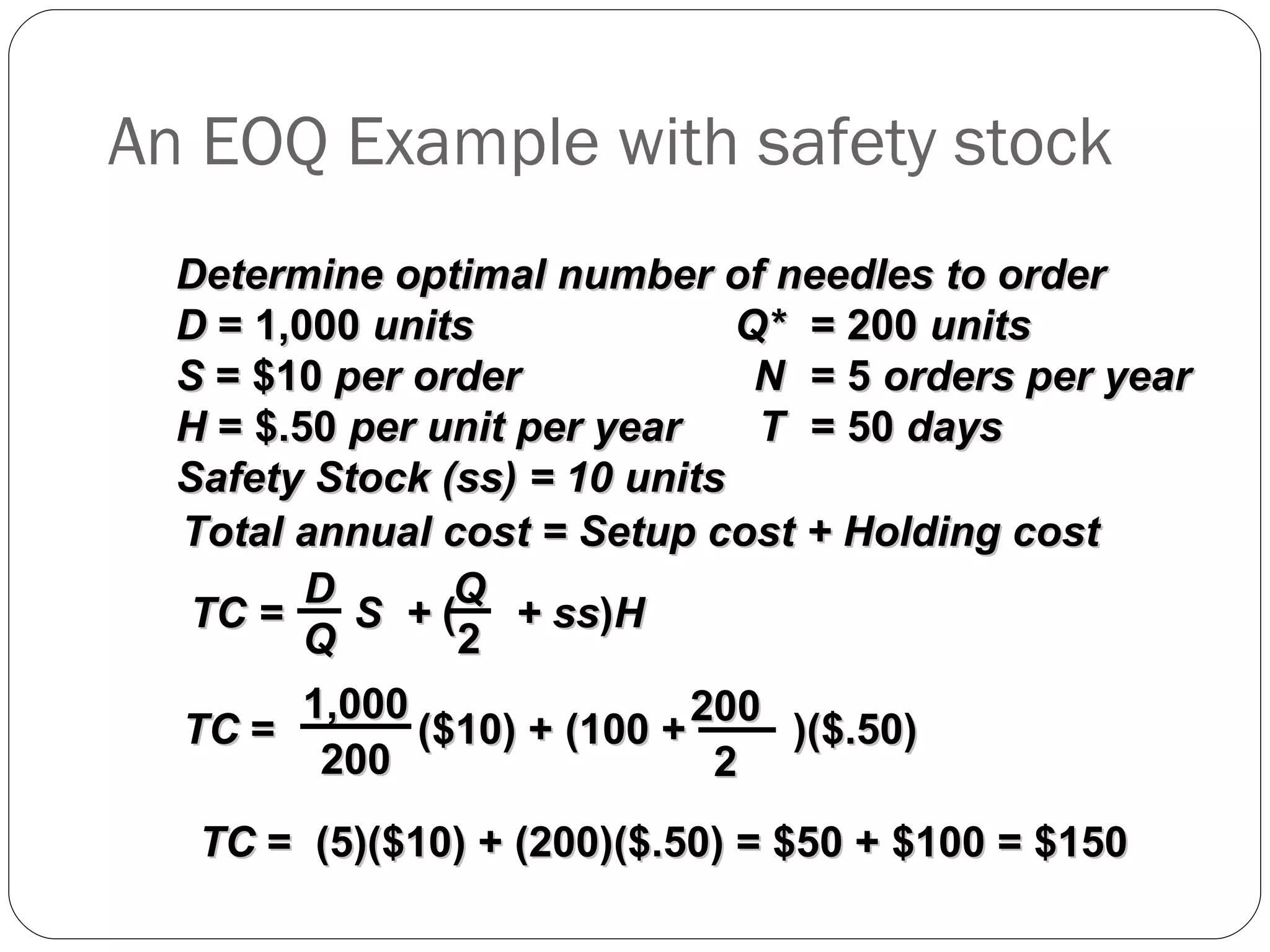

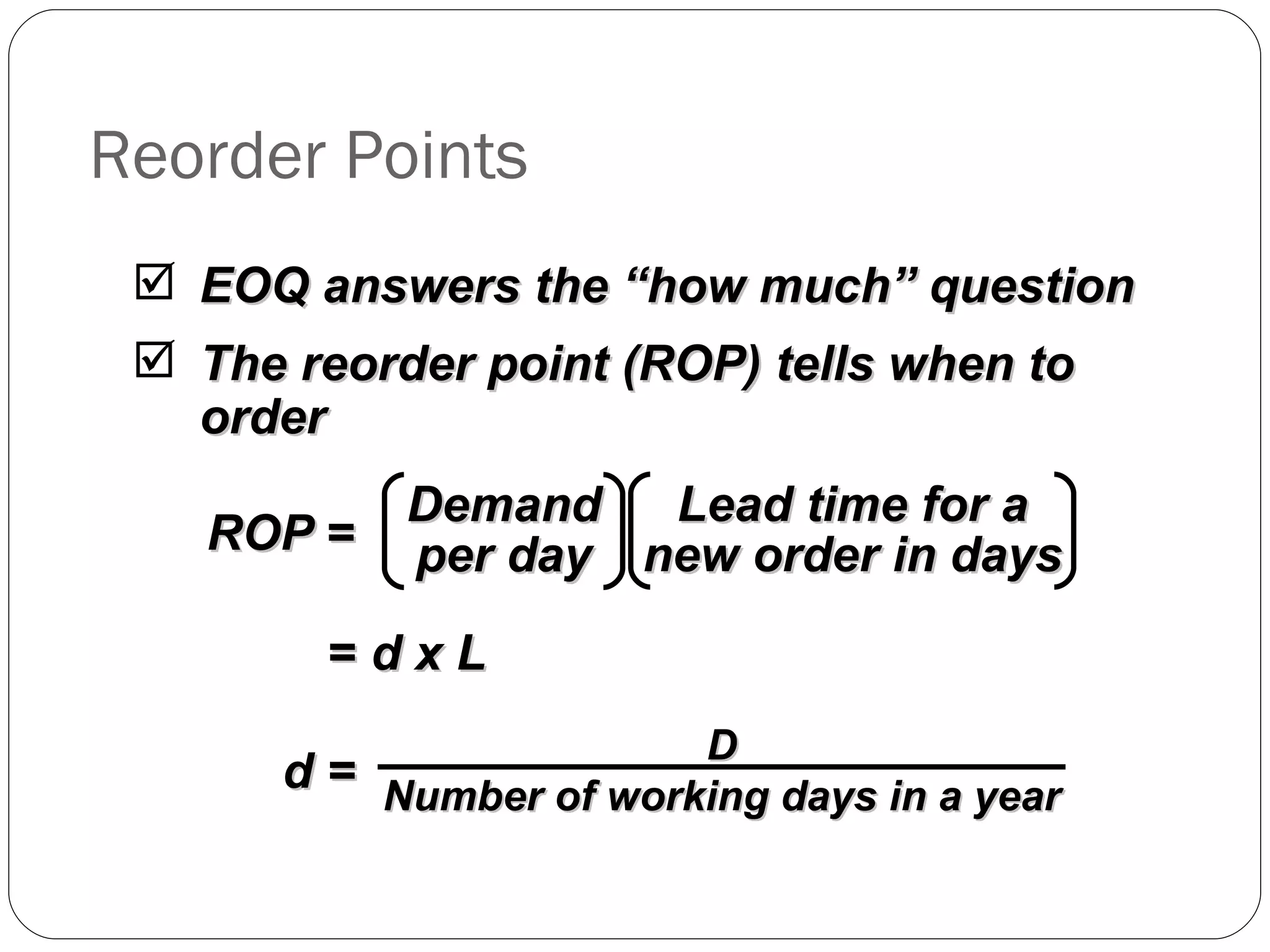

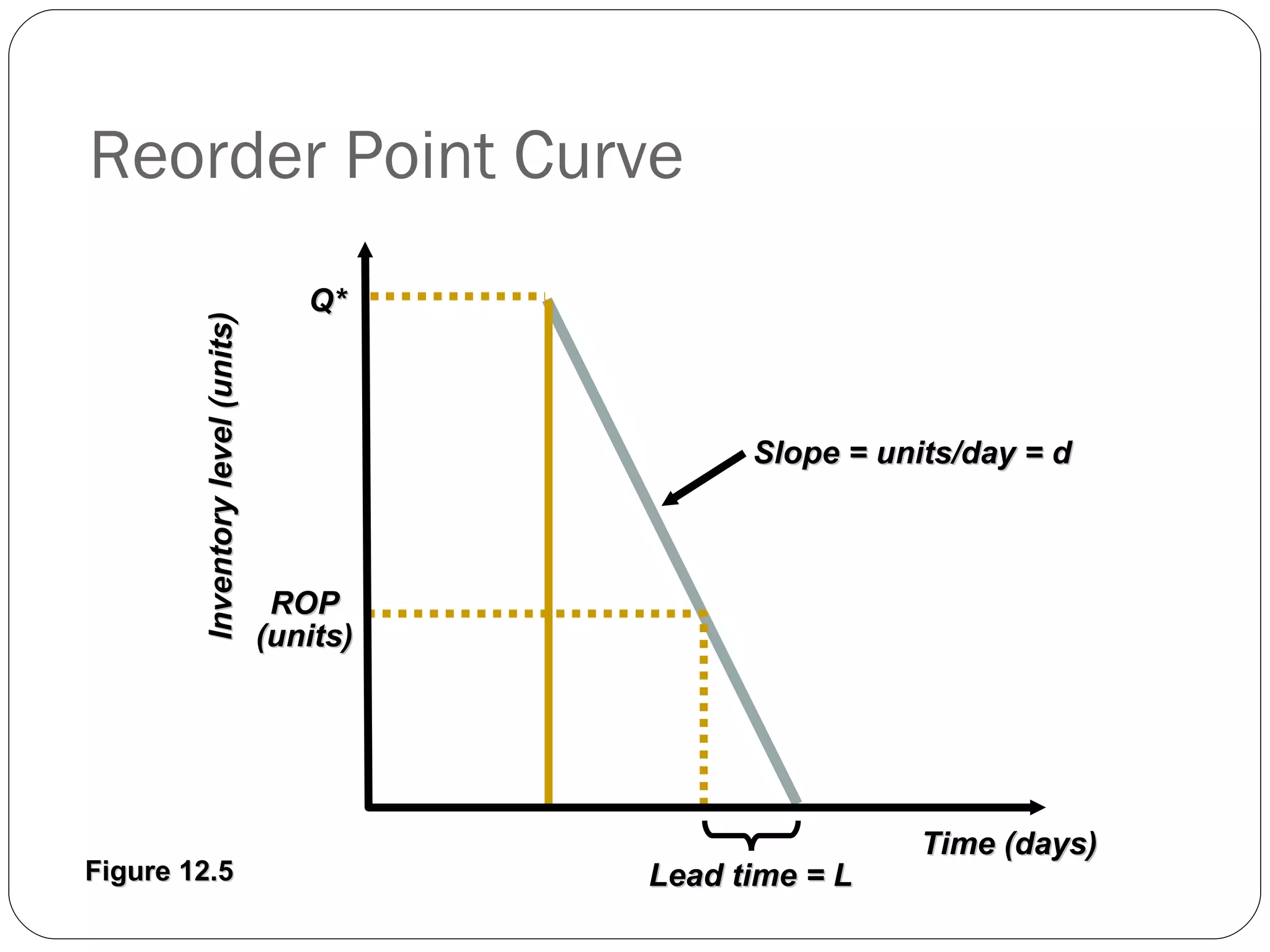

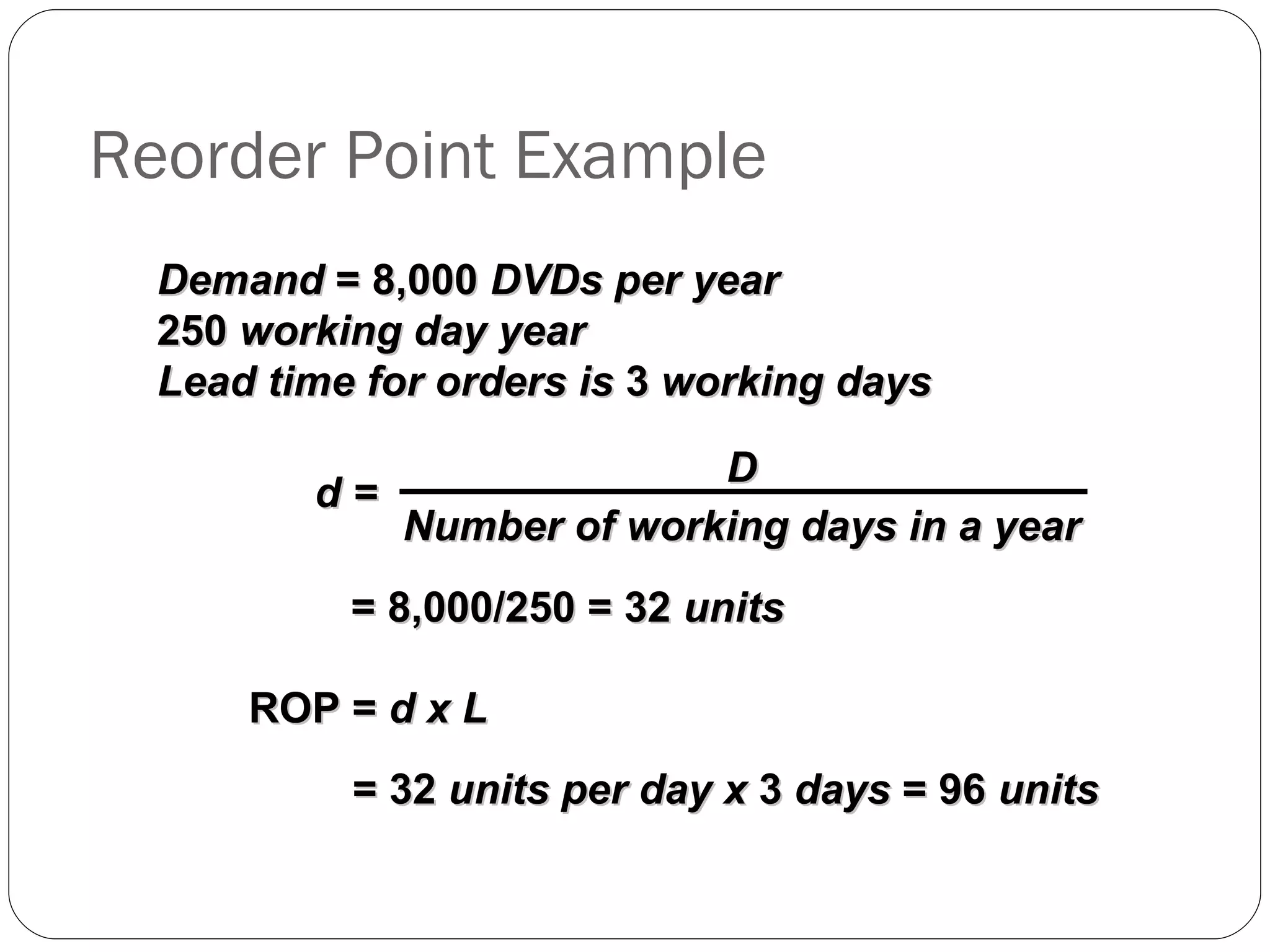

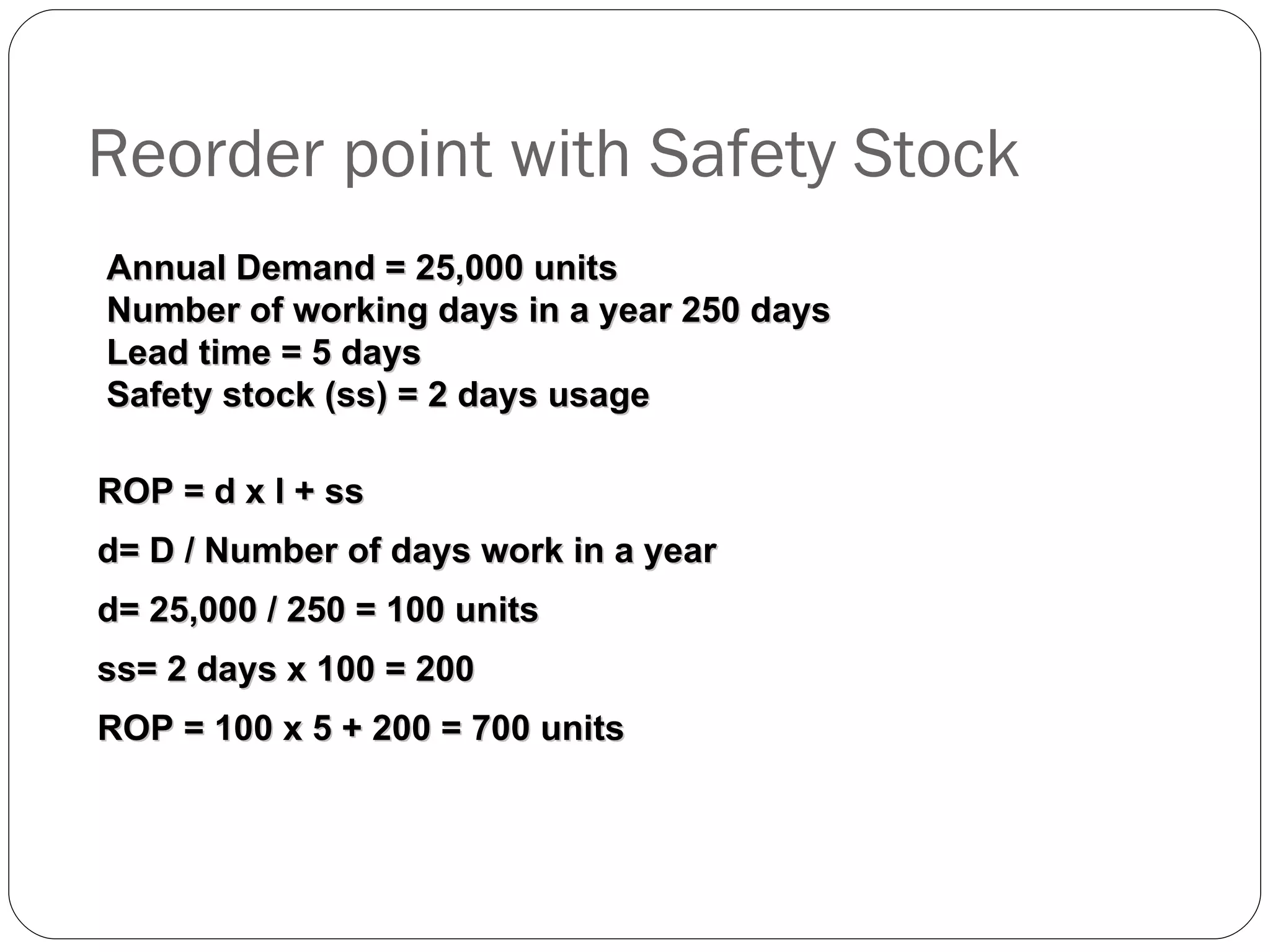

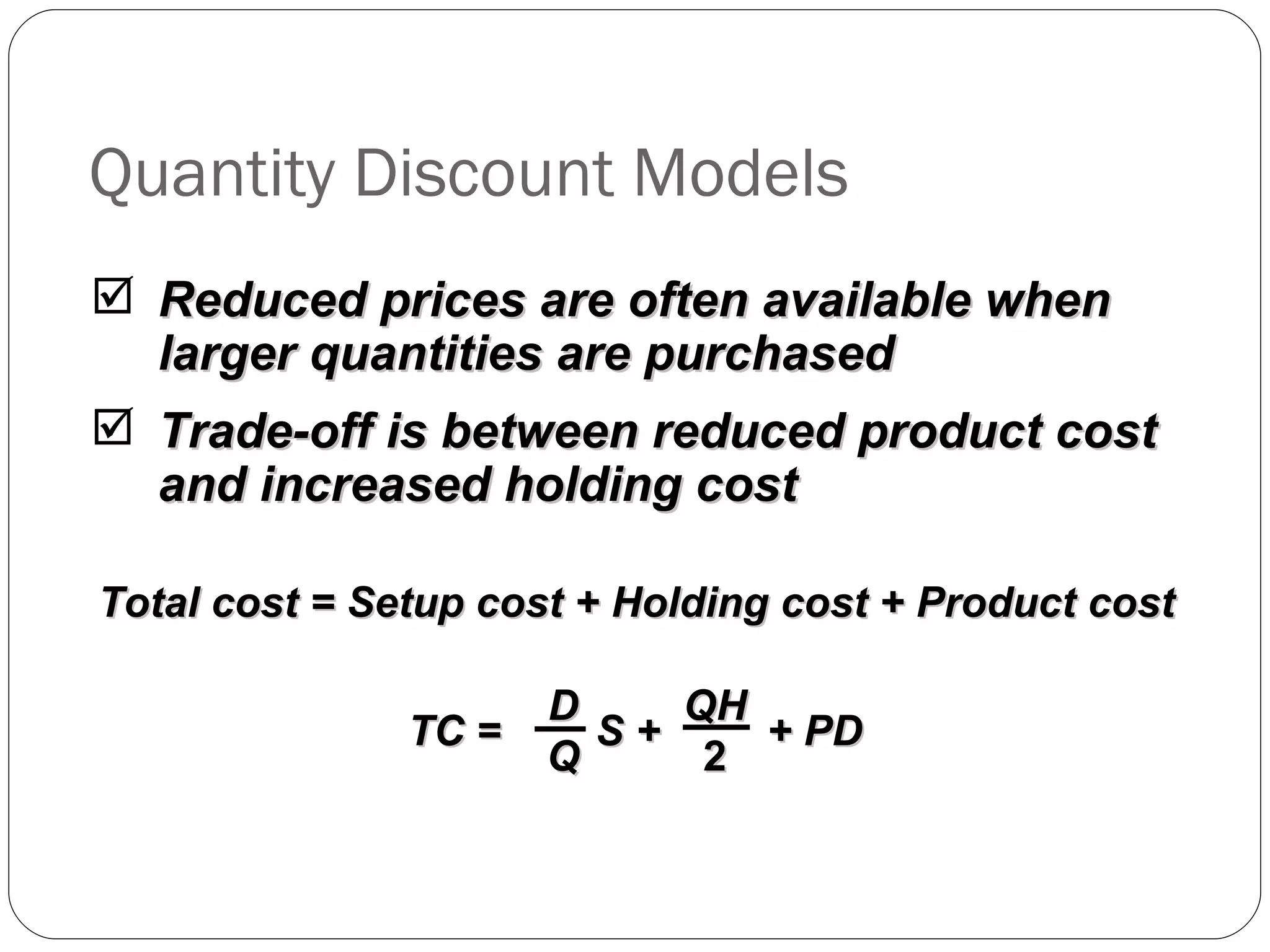

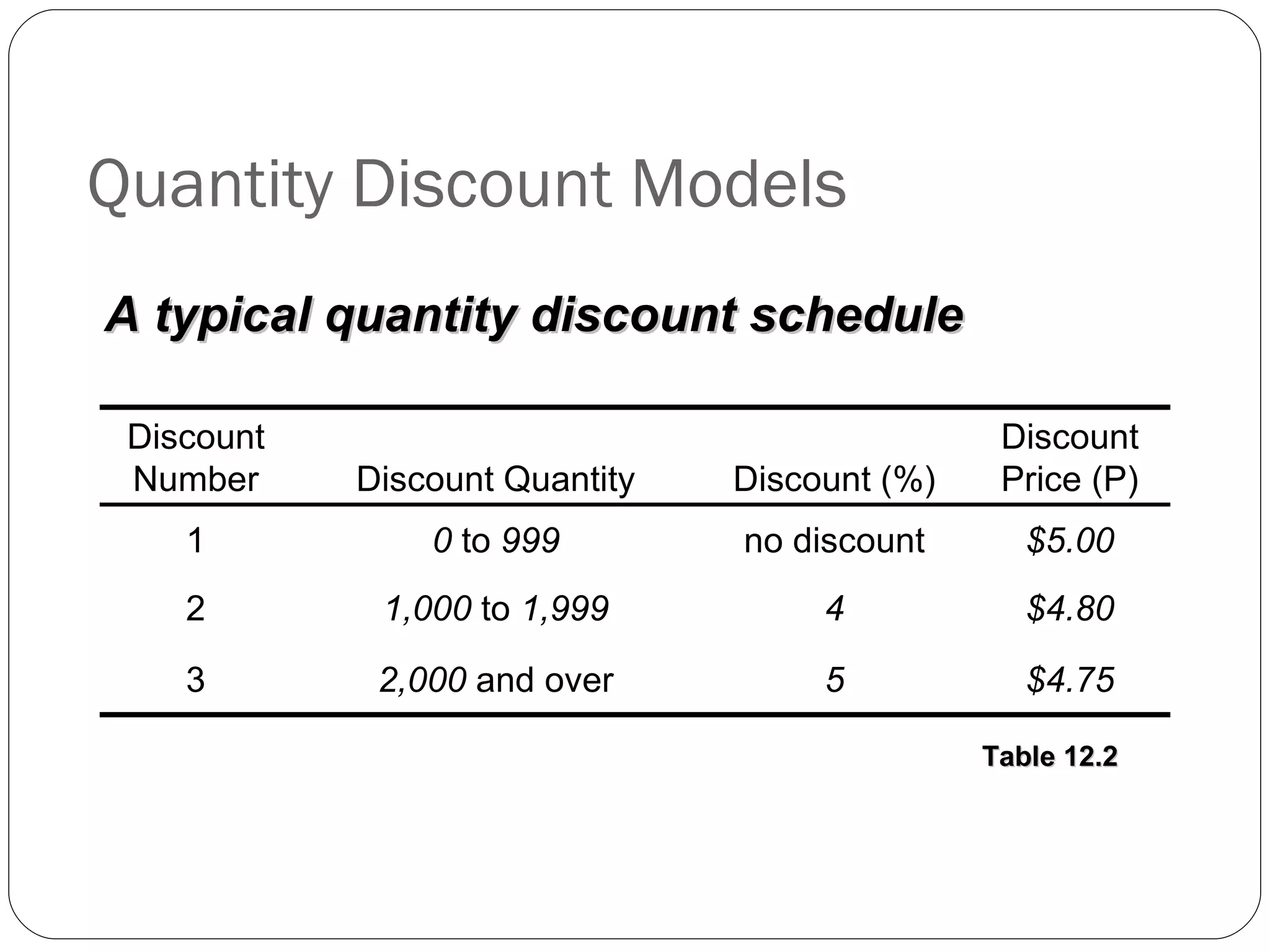

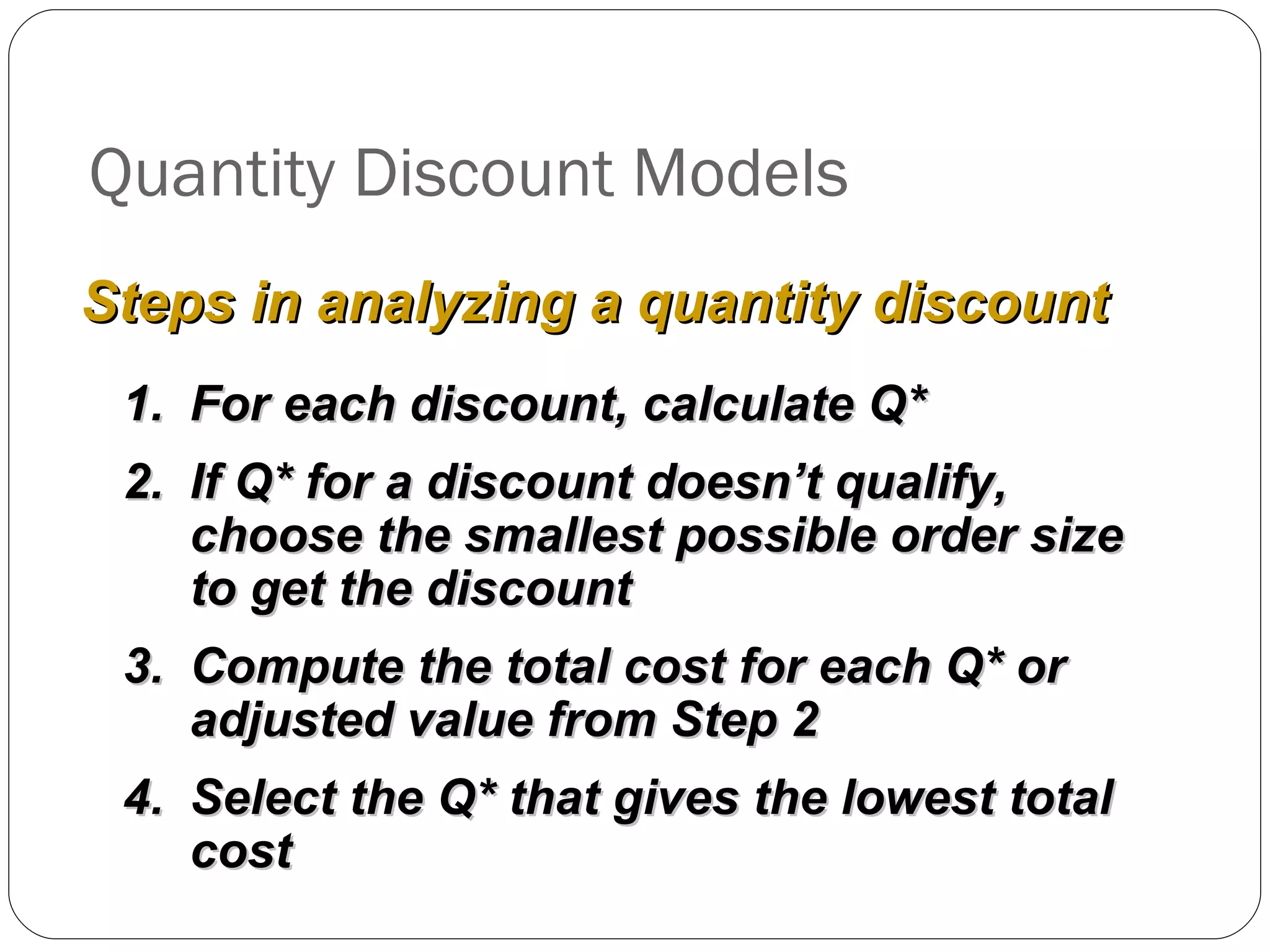

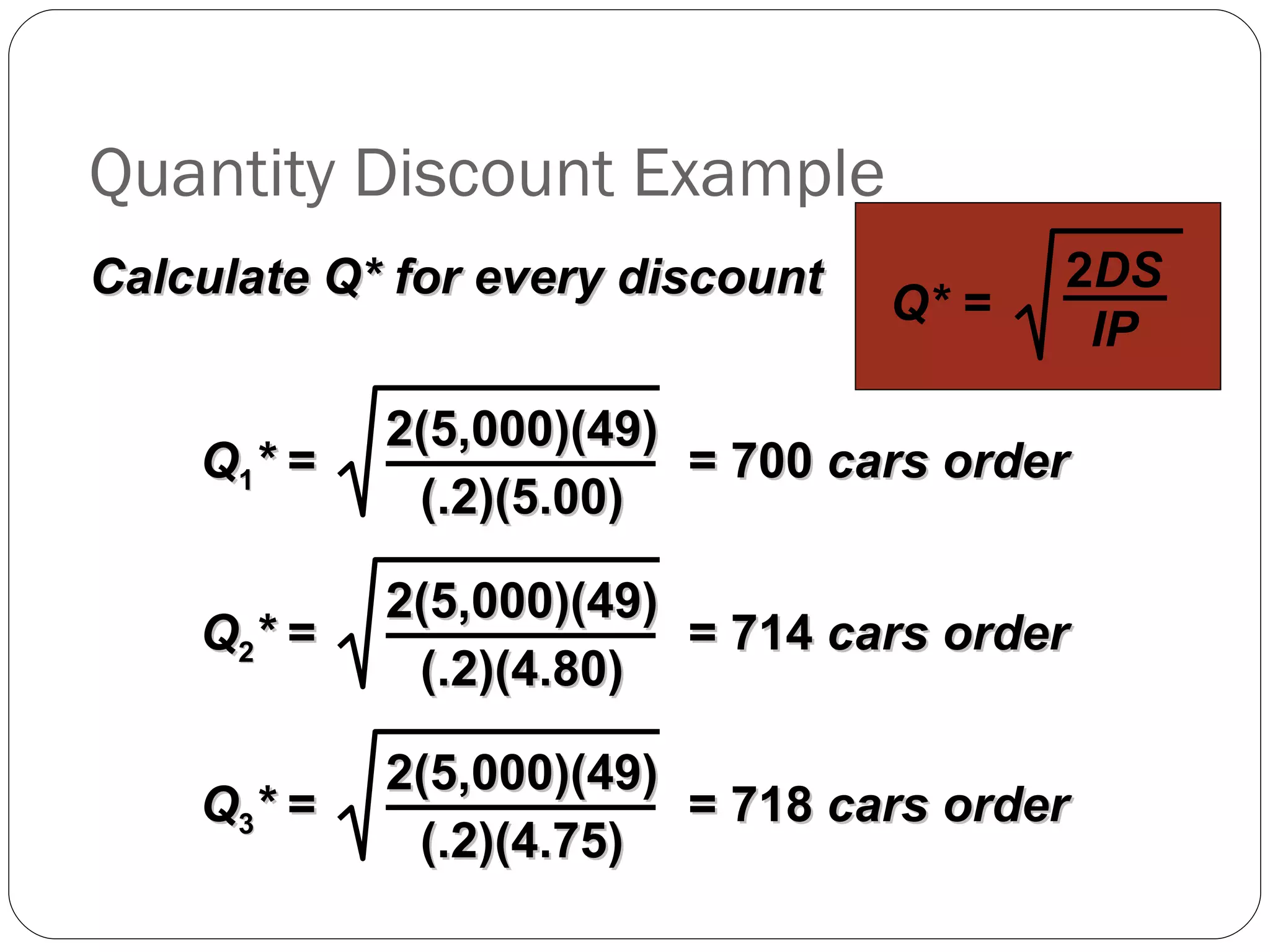

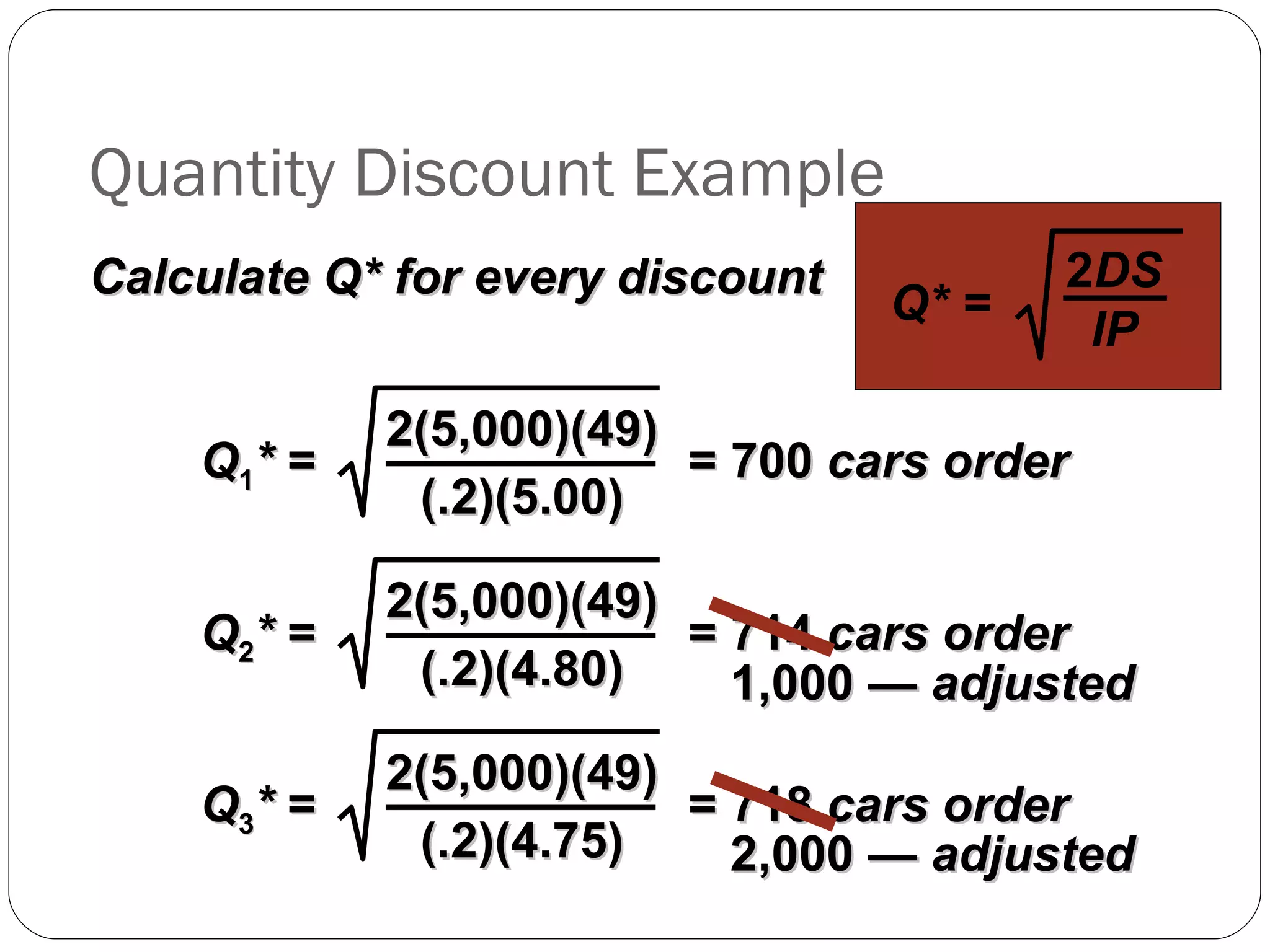

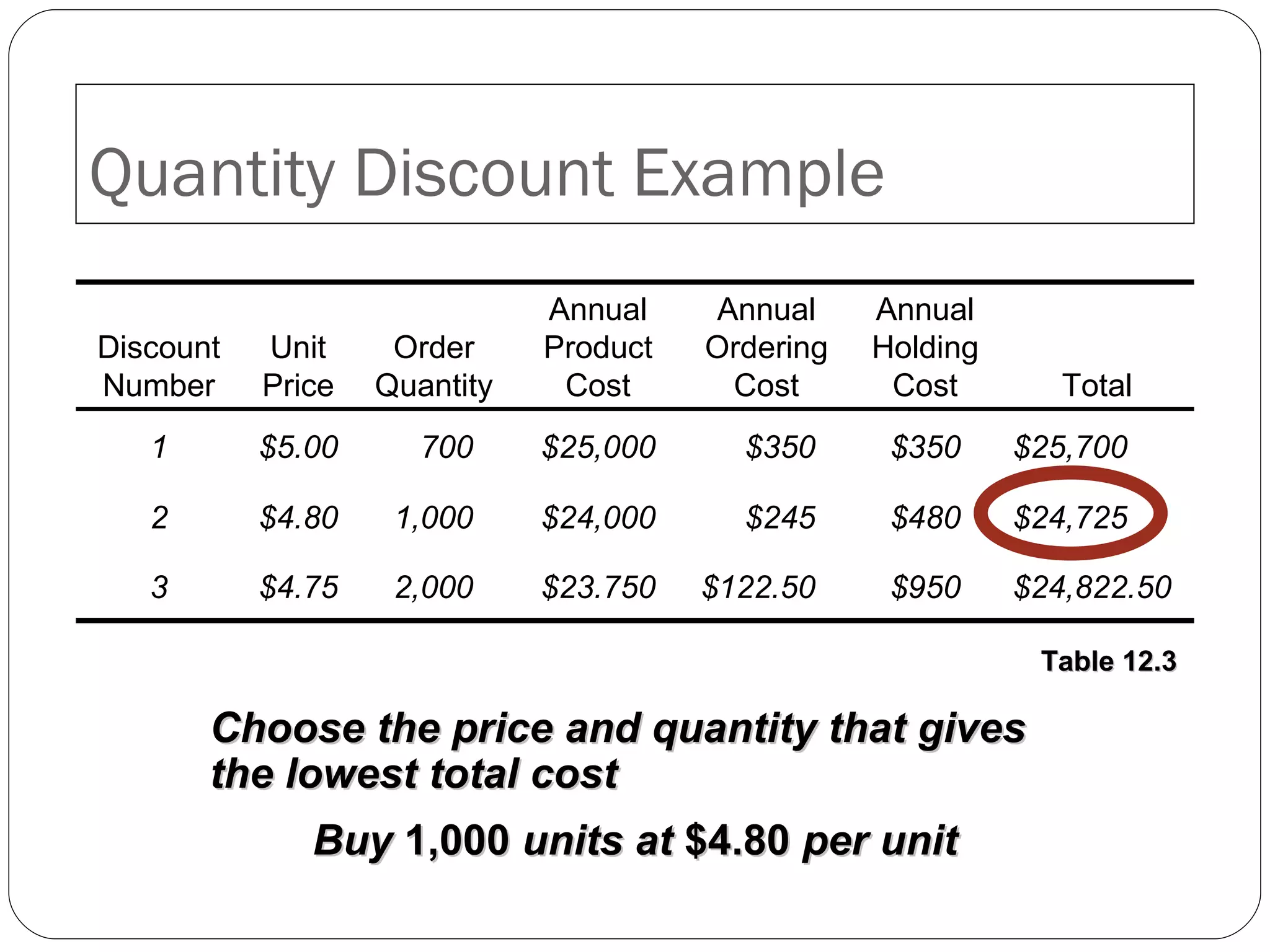

The document discusses inventory management concepts including the economic order quantity (EOQ) model. It provides the assumptions and equations of the EOQ model, which determines the optimal order quantity by minimizing total costs of ordering and holding inventory. It also discusses other inventory models like production order quantity and quantity discounts, as well as inventory classifications like ABC analysis.