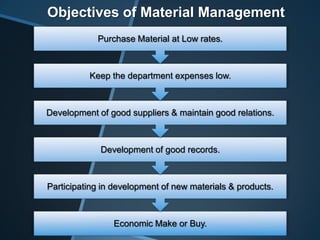

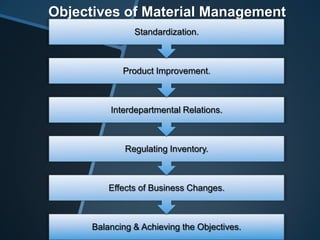

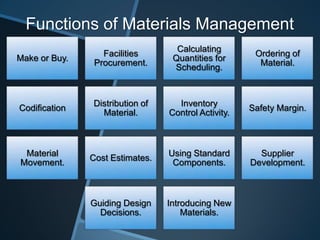

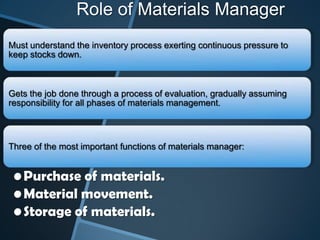

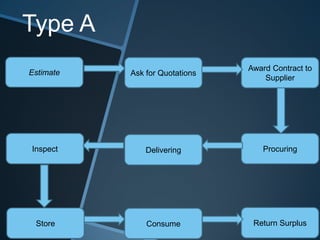

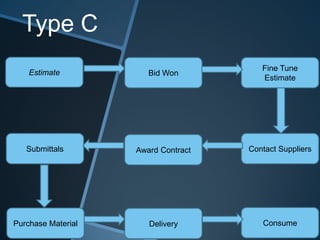

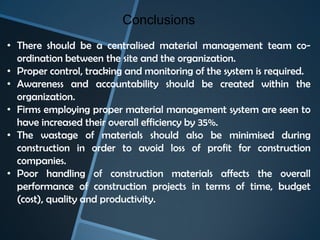

This document summarizes a seminar on material management on construction sites. It discusses the introduction to materials and material management. It outlines the objectives of material management such as making economic decisions and developing good supplier relations. It also discusses the functions of material management including procurement, inventory control, and cost estimates. The role of the material manager is described as understanding inventory processes and achieving inventory control. Finally, some prevalent material management practices used in construction are presented including estimating, procuring, delivering, and consuming materials.