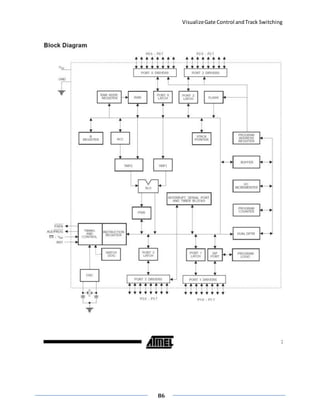

The document outlines a project on 'visualize gate control and track switching' aimed at improving safety and communication in India's railway system, which suffers from accidents mainly due to human errors and inadequate technology. It describes the design and operation of hardware and software components, including IR sensors for automatic gate control, a microcontroller for processing, and a master control system for managing train track switching. The project aims to enhance safety by automating train detection and signaling to prevent collisions and accidents at railway crossings.

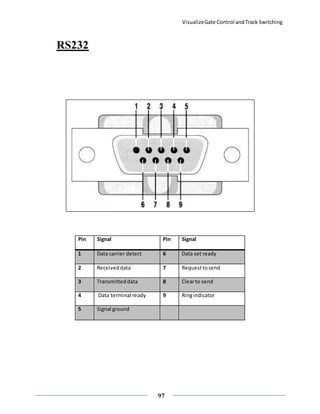

![VisualizeGate Control andTrack Switching

9

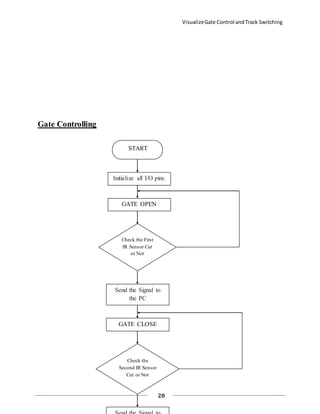

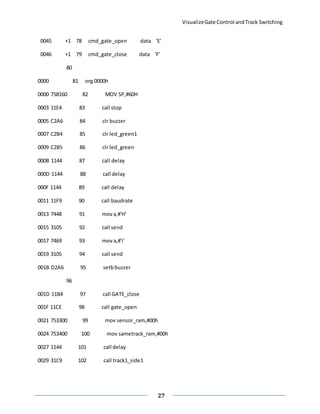

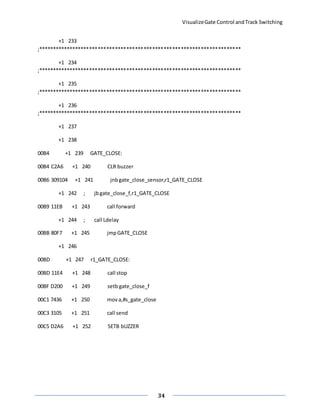

DESIGN PROCEDURE

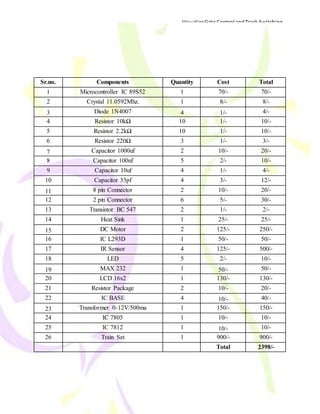

a) HARDWARE:

• Principle of Operation:

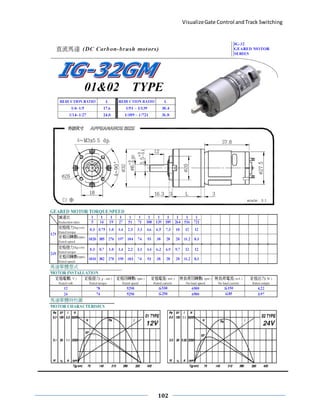

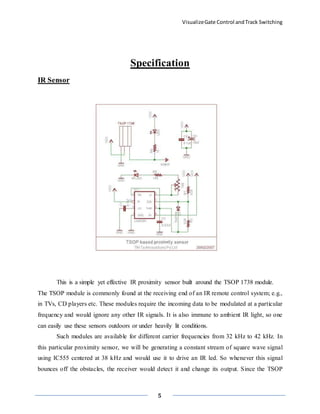

1. We are using the Infrared sensor (IR) pairs for detecting the train. As the train

obstructs IR signals, IR will send the received signals to the controller indicating that

the train is arrived. When the train obstructs the 1st IR sensor, it will turn ON buzzer

for particular period of time and then the gate will automatically get closed.

2. The buzzer is basically used as a warning alert for people near the railway gate.

3. We can calculate the speed of train using distance between two IR sensors (fixed) and

the time difference required by train to obstruct the 2 IR sensors.

4. When the train is arriving from 1 side, the signal on the same track will indicate red

signal to opposite direction.

5. If we want to route the train on different tracks then we can switch the tracks using

master controller (PC).

6. These all are represented on computer (master controller) and provide master control

to operator. [I.e. gate status, signal status, tracks switching, speed measurement,

position of train.]

7. IR sensors are also used for the automatic railway gate control which is performed by

using the outputs of the IR sensors which are given to the DC motor used for the gate.

8. The status of the railway gate is represented on the PC and it is also controlled by the

master controller (PC).](https://image.slidesharecdn.com/report-151204201542-lva1-app6891/85/INTELIGENT-RAILWAY-SYSTEM-9-320.jpg)

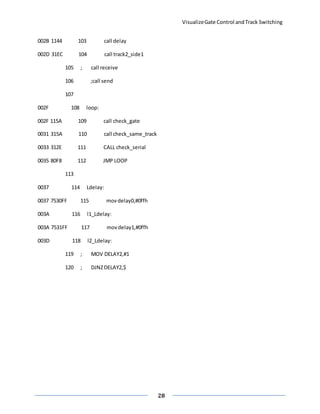

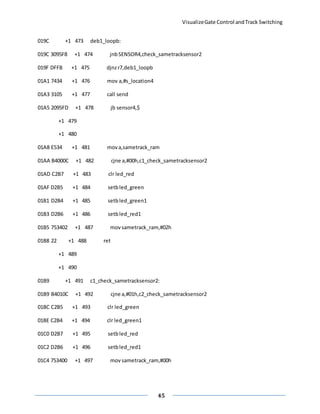

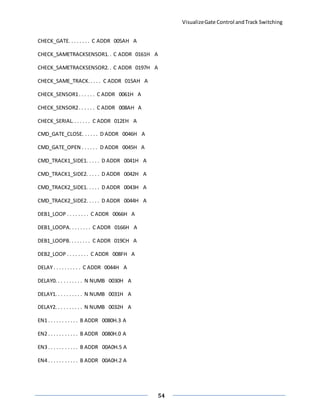

![VisualizeGate Control andTrack Switching

23

Software Listing

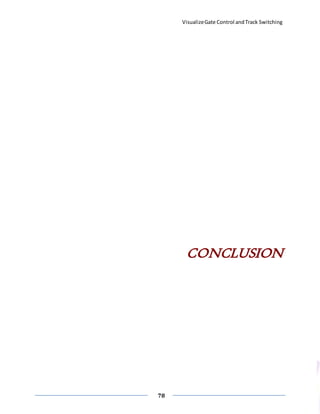

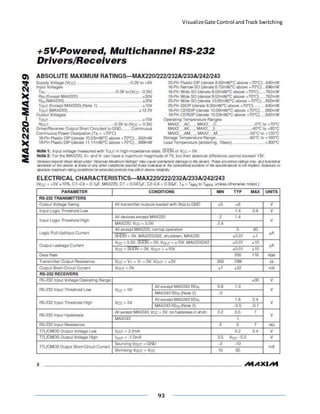

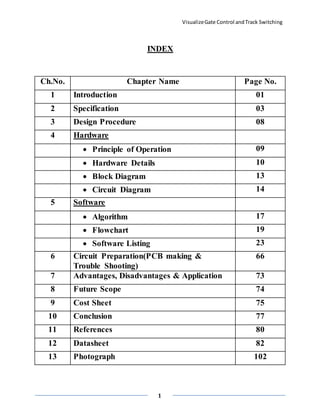

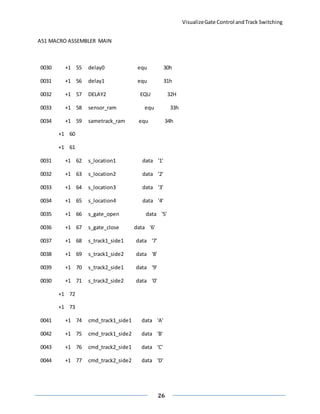

A] Assembly language programming

A51 MACRO ASSEMBLER MAIN

MACRO ASSEMBLER A51 V8.01

OBJECT MODULE PLACED IN main.OBJ

ASSEMBLER INVOKEDBY: C:KeilC51BINA51.EXEmain.asmSET(SMALL) DEBUG EP

LOC OBJ LINE SOURCE

1 ;$include (ini.inc)

0093 +1 2 SENSOR1 BIT p1.3 ;for gate

0092 +1 3 SENSOR2 BIT p1.2 ;for gate

0091 +1 4 gate_close_sensor bit P1.1

0090 +1 5 tracksw_fb1 bit P1.0

0096 +1 6 tracksw_fb2 bit P1.6

0094 +1 7 SENSOR3 BIT p1.4 ;forspeedsame tra

ck

0095 +1 8 SENSOR4 BIT p1.5 ;forsame track](https://image.slidesharecdn.com/report-151204201542-lva1-app6891/85/INTELIGENT-RAILWAY-SYSTEM-23-320.jpg)

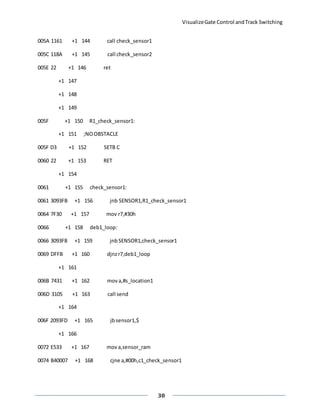

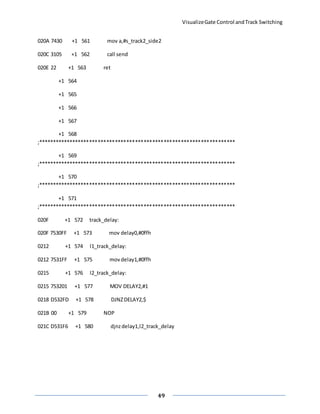

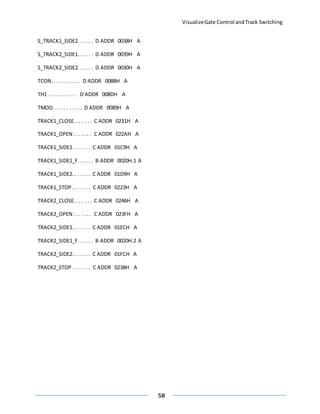

![VisualizeGate Control andTrack Switching

60

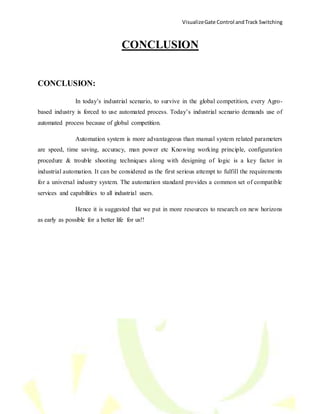

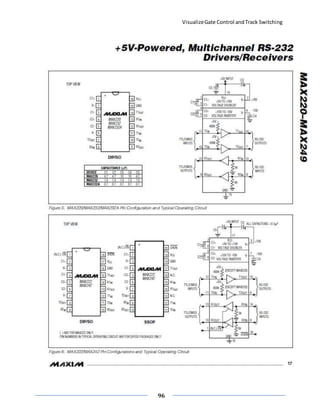

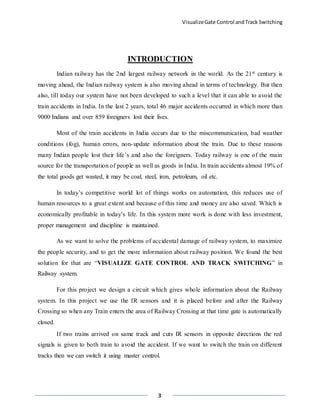

B] Visual Basic programming

OptionExplicit

DimInputStringBufferAsString

DimWriteStringBufferAsString

DimTagno As String

'Dim countAs Integer

Private Subcmdconnect_Click()

If cmdconnect.Caption="CONNECT"Then

MSComm1.CommPort= txtcommport.Text

MSComm1.PortOpen=True

cmdconnect.Caption="DISCONNECT"

MSComm1.RThreshold=1

ElseIf cmdconnect.Caption="DISCONNECT"Then

MSComm1.PortOpen=False

cmdconnect.Caption="CONNECT"

End If

End Sub

Private SubCommand1_Click()

MSComm1.Output= "E"

End Sub

Private SubCommand2_Click()

MSComm1.Output= "A"](https://image.slidesharecdn.com/report-151204201542-lva1-app6891/85/INTELIGENT-RAILWAY-SYSTEM-60-320.jpg)