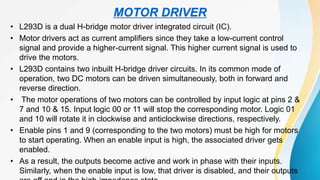

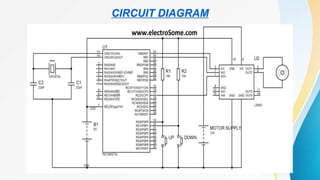

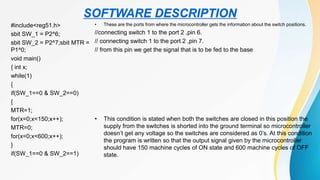

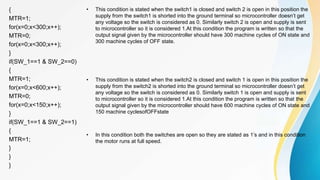

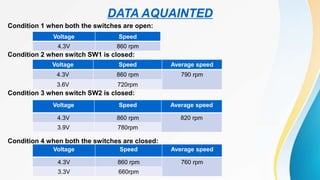

The document discusses speed control of a DC motor using a microcontroller. It describes how a microcontroller like the PIC16F877A can be used along with a motor driver IC like the L293D to control the speed of a DC motor. The circuit diagram and programming code for the microcontroller are provided to output PWM signals to the motor driver and thereby regulate the motor speed based on the position of two switches. Speed can be increased or decreased by adjusting the on/off times of the PWM signal sent to the motor.

![Share 'speed control_of_dc_motor_using_microcontroller.pptx'[1][1]](https://image.slidesharecdn.com/sharespeedcontrolofdcmotorusingmicrocontroller-181012151950/85/Share-speed-control_of_dc_motor_using_microcontroller-pptx-1-1-18-320.jpg)