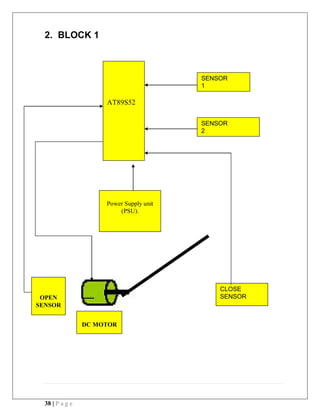

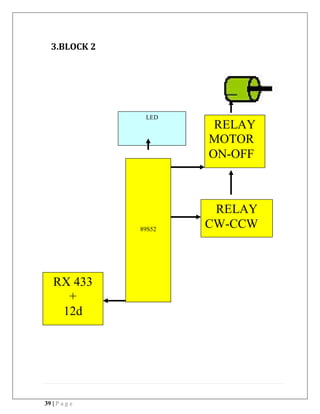

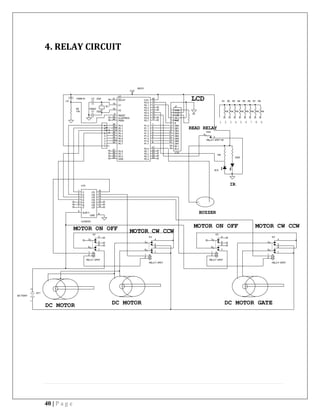

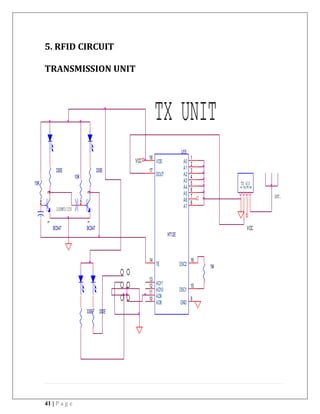

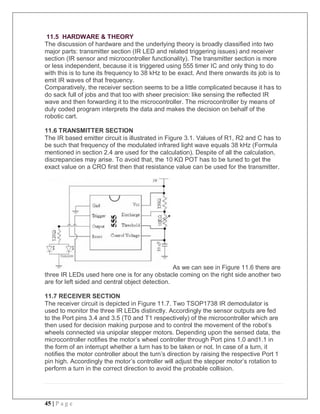

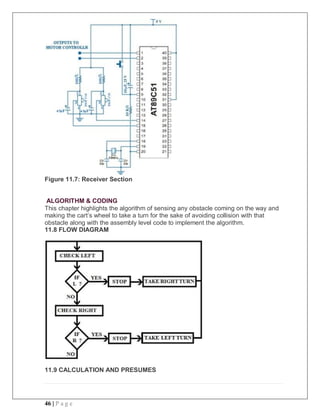

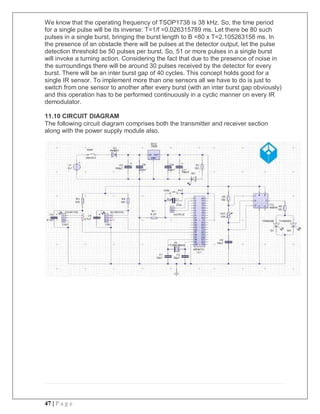

The document describes a student project on an automatic railway gate control system. It includes a declaration signed by four students stating that the work is original. It also includes an acknowledgements section thanking their supervisor and institution for support and resources. The abstract provides a brief overview of the system, which uses sensors to automatically open and close railway gates based on a train's proximity.