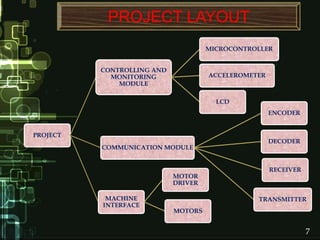

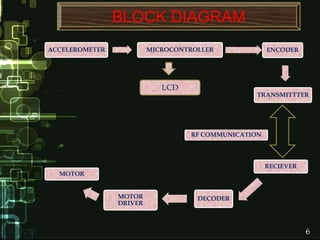

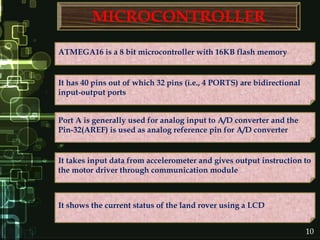

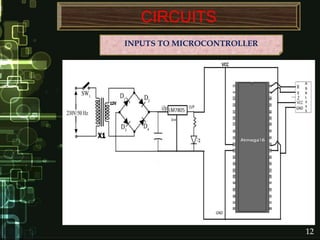

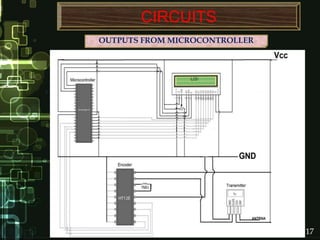

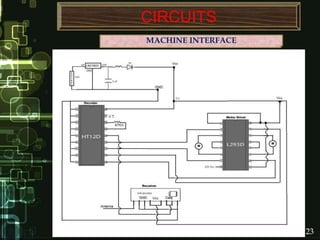

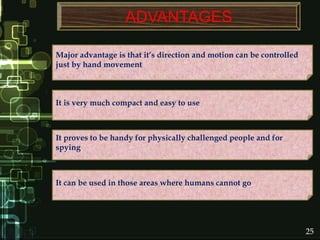

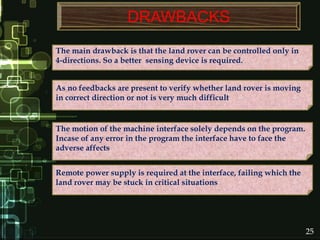

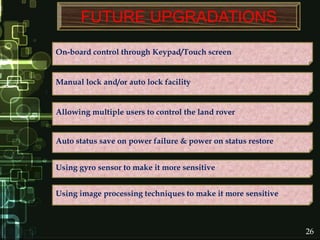

This document describes a hand gesture controlled wireless land rover. The project uses an accelerometer to detect hand gestures which are transmitted via RF to control motors and move the land rover in four directions. The key components are a microcontroller, accelerometer, encoder, transmitter, receiver, motor driver and motors. Programming is done using AVR studio to flash the microcontroller. Advantages include compact size and wireless control using natural hand gestures. Future enhancements could include onboard controls, image processing for improved sensitivity and gyro sensors.