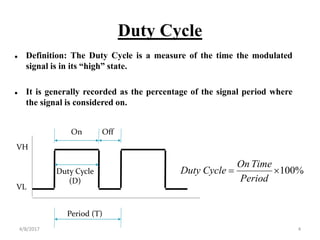

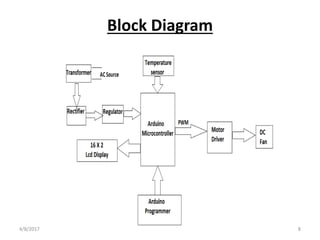

This document discusses speed control of a DC motor using pulse width modulation (PWM) technique. PWM controls the speed of a DC fan motor based on temperature readings from a DHT22 temperature sensor. The Arduino microcontroller measures the temperature and humidity using the DHT22 sensor and adjusts the duty cycle of the PWM signal to the motor to control its speed according to the measured temperature levels. By varying the on-off time of the PWM signal, the average power delivered to the motor can be adjusted to control its speed for different temperature ranges.